All-in-one platform for the best digitalization of Your Factory

Everything you need for the digitalization of your plant.

We have one goal – to guide you through the entire digital transformation process in the most straightforward and efficient way so that your company can reap long-term benefits, and you and all employees can find satisfaction in your work.

The digital transformation of your manufacturing plant is a journey that leads from data collection, through optimization, to process automation. This journey requires a plan, methods, tools, and partners, all of which you will find on the DBR77 Platform.

Digital Transformation

in Four Steps

Digital Development Roadmap

Diagnosis and Development Plan

Big Data DBR77

Data Processing

Digital Twin and AI

Visualization and Production

Marketplace

Automation and Robotics

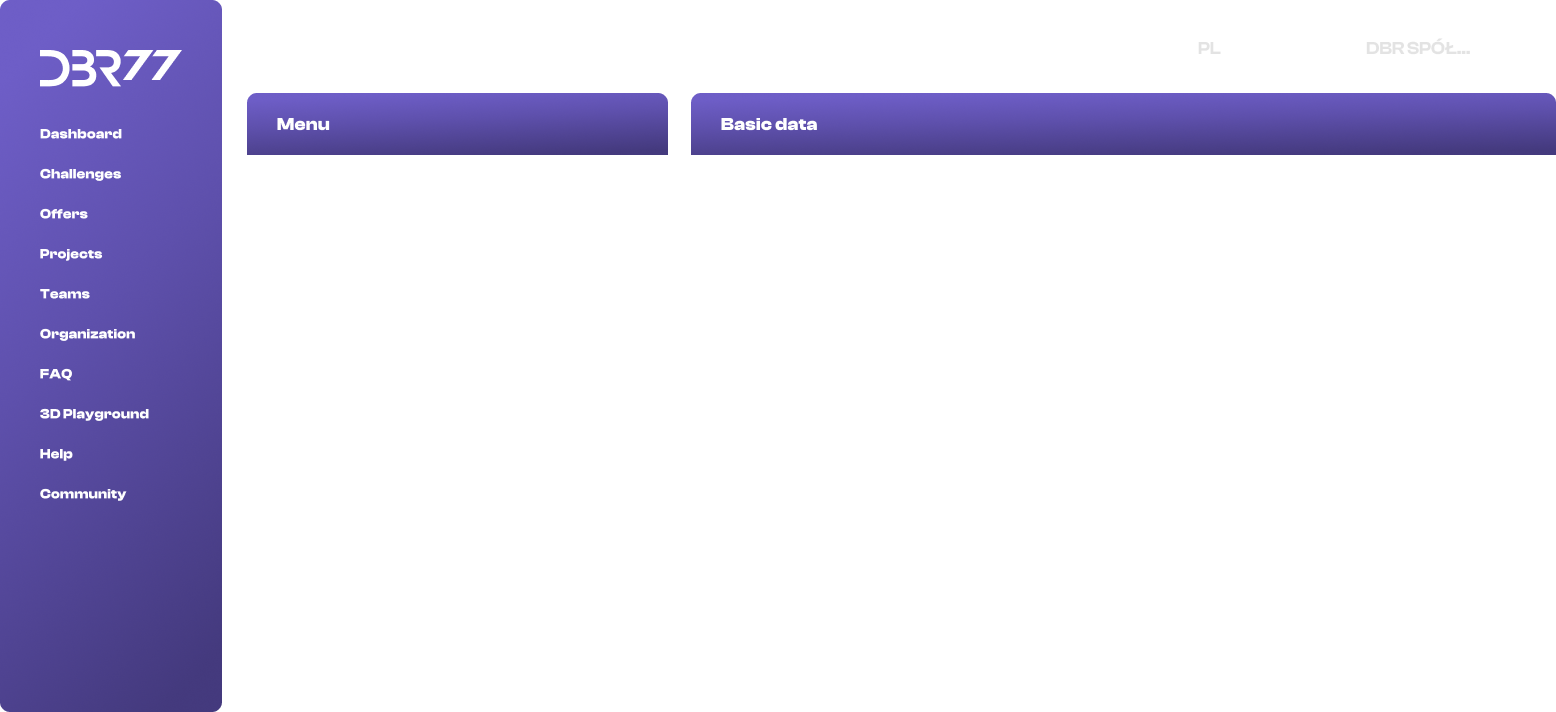

Digital Development Roadmap

Plan your transformation and take meaningful steps.

The Digitalization Roadmap by DBR77 is a tool used by practitioners to create a comprehensive and long-term plan for the transformation of a manufacturing company from the analog to the digital world. It is your e-strategy for the digital era. Conduct an analysis of the current state and discover the next meaningful steps to take!

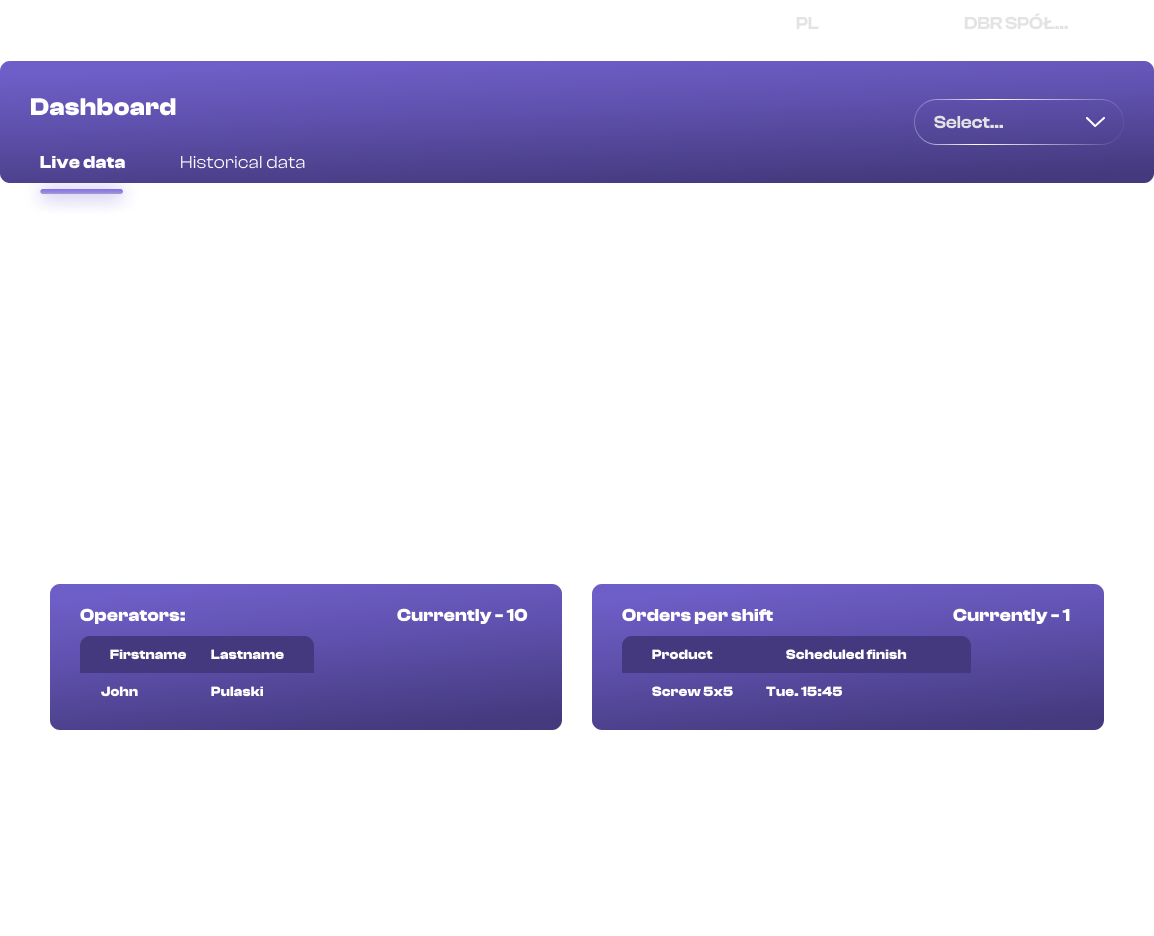

Big Data DBR77

Thoroughly Diagnose Production

Data is the foundation and starting point of digital transformation. Utilize your production Big Data to optimize processes and make informed decisions in a rapidly changing market. Precisely assess the efficiency of individual units or complex production lines. Analyze anomalies and optimize product flow. Monitor, set, and objectively analyze machine and employee KPIs. Empower your workforce with an AI-powered early warning system. Embrace the power of data-driven decision-making and lead your organization to new heights of productivity and success.

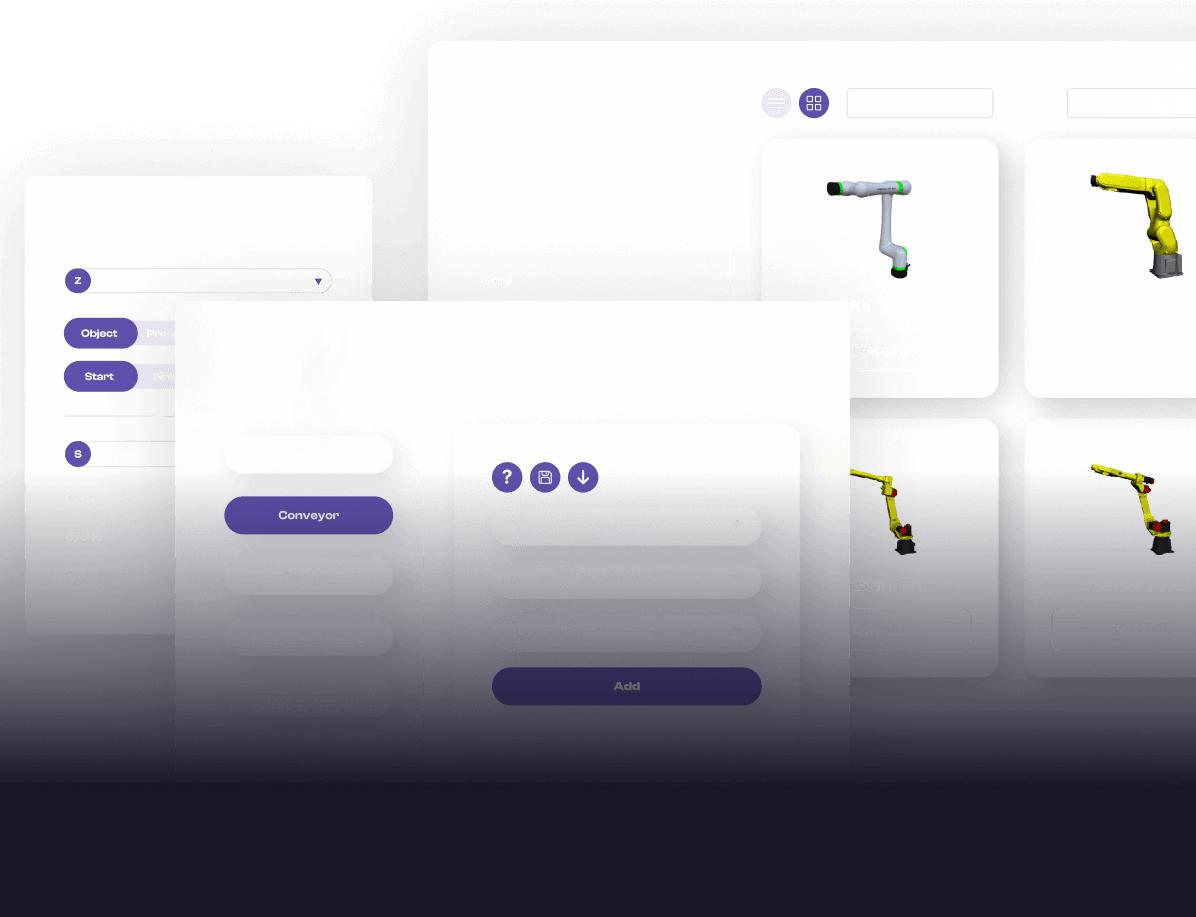

Digital Twin plus AI

Enhance the Efficiency of Your Entire Facility

Virtual representation of the production world and algorithmic support for manufacturing processes lead to a significant increase in your efficiency and effectiveness on the production lines. The digital twin of your facility is not just a symbol of successful digitalization, but also the dream of many production managers and executives. With our solution, even small and medium-sized manufacturing plants can access this technology. Elevate your competitiveness, production efficiency, response time to unexpected challenges, planning accuracy, and gain real insight into what is happening on your production floors in just a few weeks.

Marketplace DBR77

Automate and Robotize

DBR77 Platform is a place that connects manufacturing facilities (Investors) with Integrators and technology providers. Visualizing the production process at an Investor’s facility can be achieved through either Digital Twin technology or by connecting to our proprietary tool called Studio 3D, available on the Marketplace. Both methods enable Integrators to select suitable technological solutions. This allows for optimal matching, procurement, and implementation of technological solutions for automation or robotization of your production and logistics.

What benefits we provide at DBR77 Platform

%

Reduction of project time

Thanks to the DBR77 platform, our customers have the opportunity to reduce the optimization and robotization time of their production stations by 50%.

%

Reduction of robotization CAPEX

Thanks to the DBR77 platform, the cost of robotization and automation of a production station can be reduced by up to 30%.

%

Increase in production productivity

The utilization of the DBR77 platform contributes to an average increase in productivity of manufacturing plants by 20%.

Discover what our customers are saying

We set the standards

in the digitalization process

We know exactly the challenges that entrepreneurs face when embarking on the path of digital transformation because we are practitioners ourselves. Platform DBR77 has one goal – to guide you through the entire process of digital transformation – from building the Digital Development Map, financial programs, simulating production processes, exploring new technologies, all the way to implementing robotization and automation processes.