Problem We Solve

3D Studio DBR77 is an advanced tool for digitally replicating production and logistics facilities, enabling interactive visualization and process analysis in a 3D environment. Powered by Unity technology, 3D Studio offers realistic space modeling, facilitating precise planning and implementation of changes in your facility.

Technology

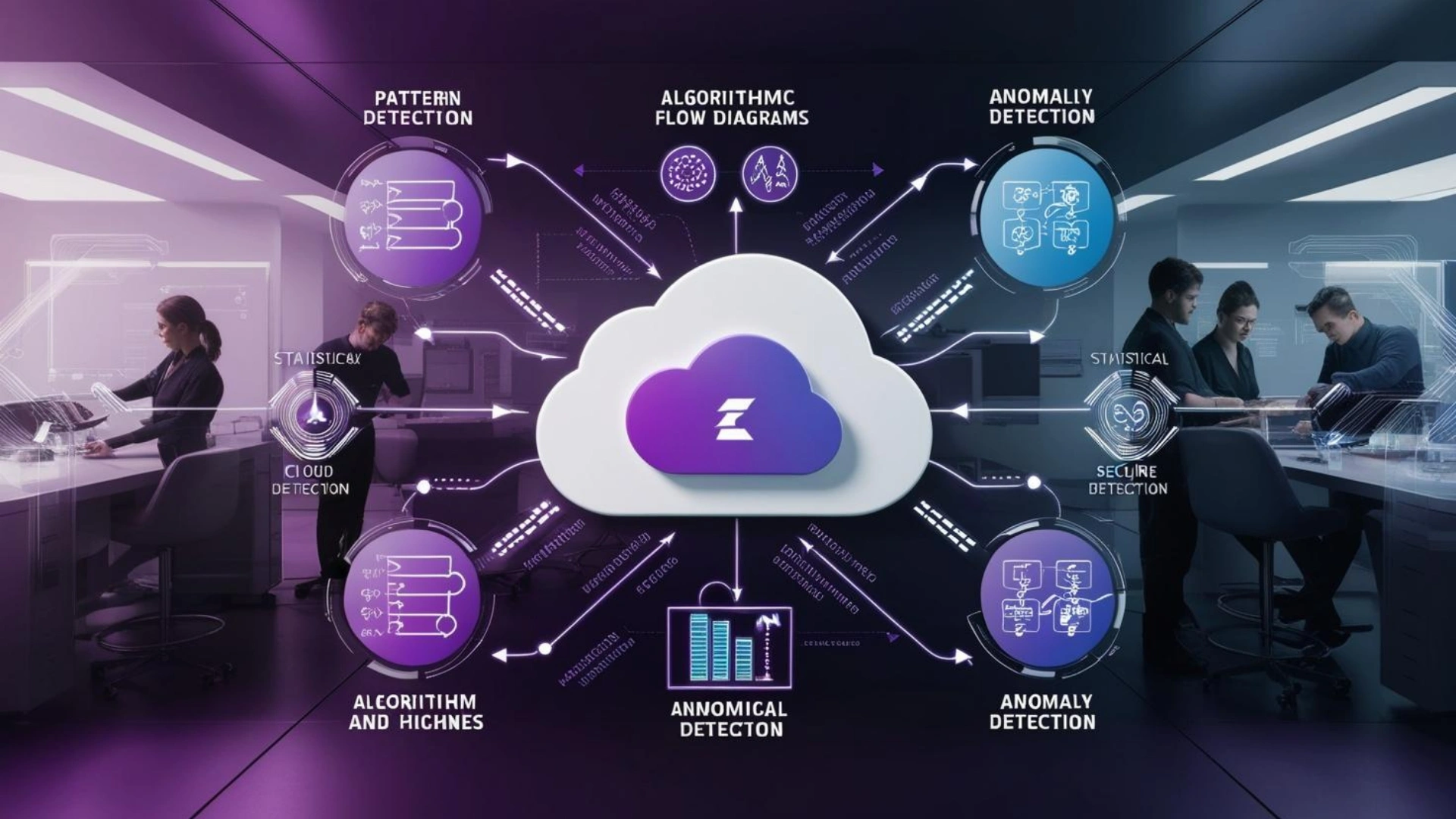

3D Studio DBR77 integrates visualization, simulation, and process analysis in a 3D environment. Designed to transform traditional 2D tools into a metaverse-like space, it enables accessible simulations from anywhere, supporting precise and efficient process design.

Simple and Intuitive Operation

The studio is designed so that any user can start designing after just one hour of training. With an intuitive interface and a new approach, even individuals without experience in industrial design can use the system. This reduces implementation time and enables faster results.

Cloud Accessibility

The studio operates in the cloud, providing access from any device. This allows teams to work on projects simultaneously in real time, accelerating decision-making processes, enabling seamless collaboration, and eliminating the need for costly on-premise infrastructure.

Integration with VR and AR

All projects created on a computer are compatible with VR and AR. 3D models are optimized for performance, even at the expense of minor graphical details. This ensures smooth virtual reality visualizations, enhancing planning precision and engaging project teams.

How 3D Studio Works

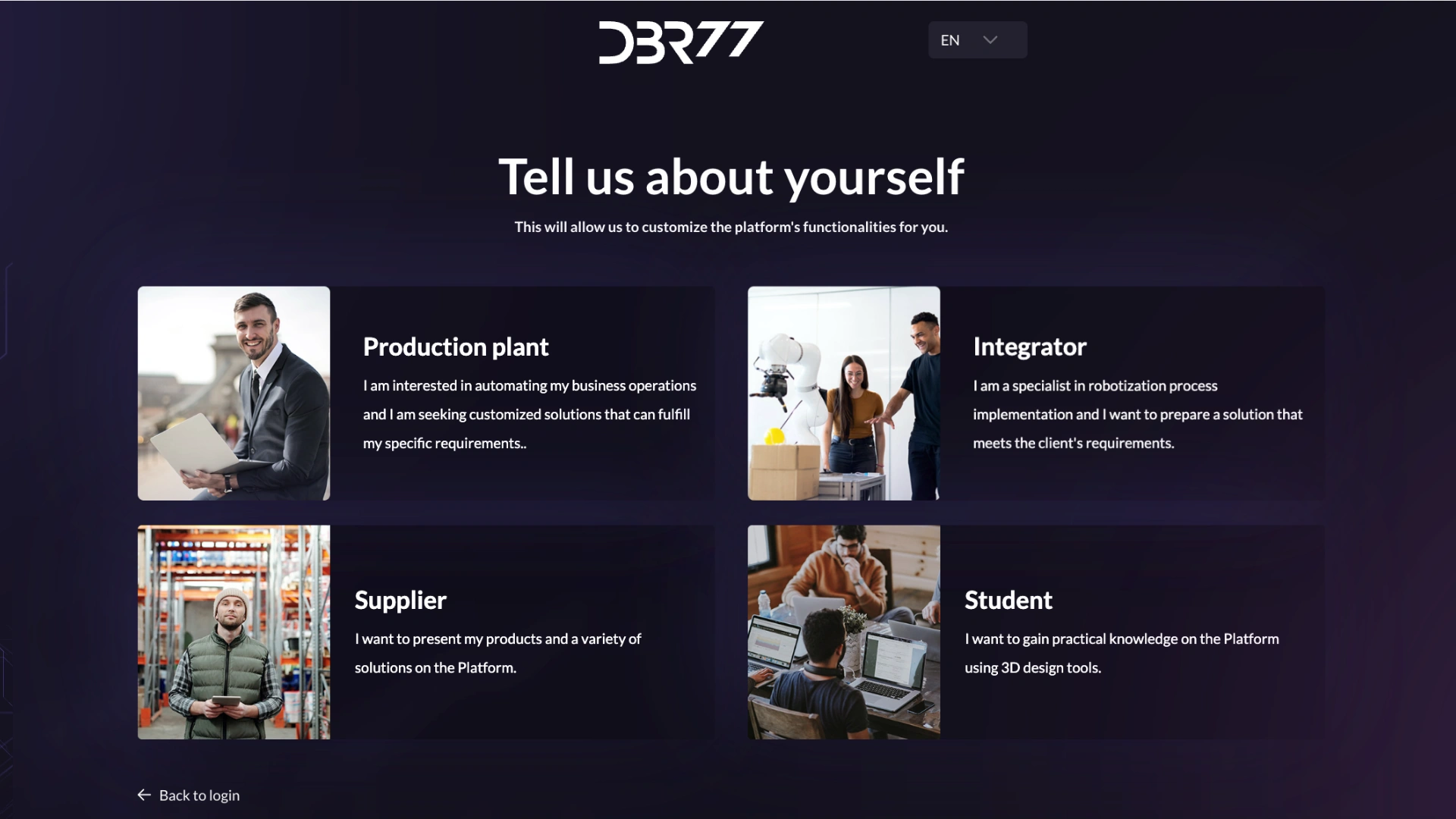

Login and Mode Selection:

After logging into the DBR77 platform, users select their preferred usage mode. The studio provides a variety of functionalities tailored to specific needs, as detailed in the technical documentation.

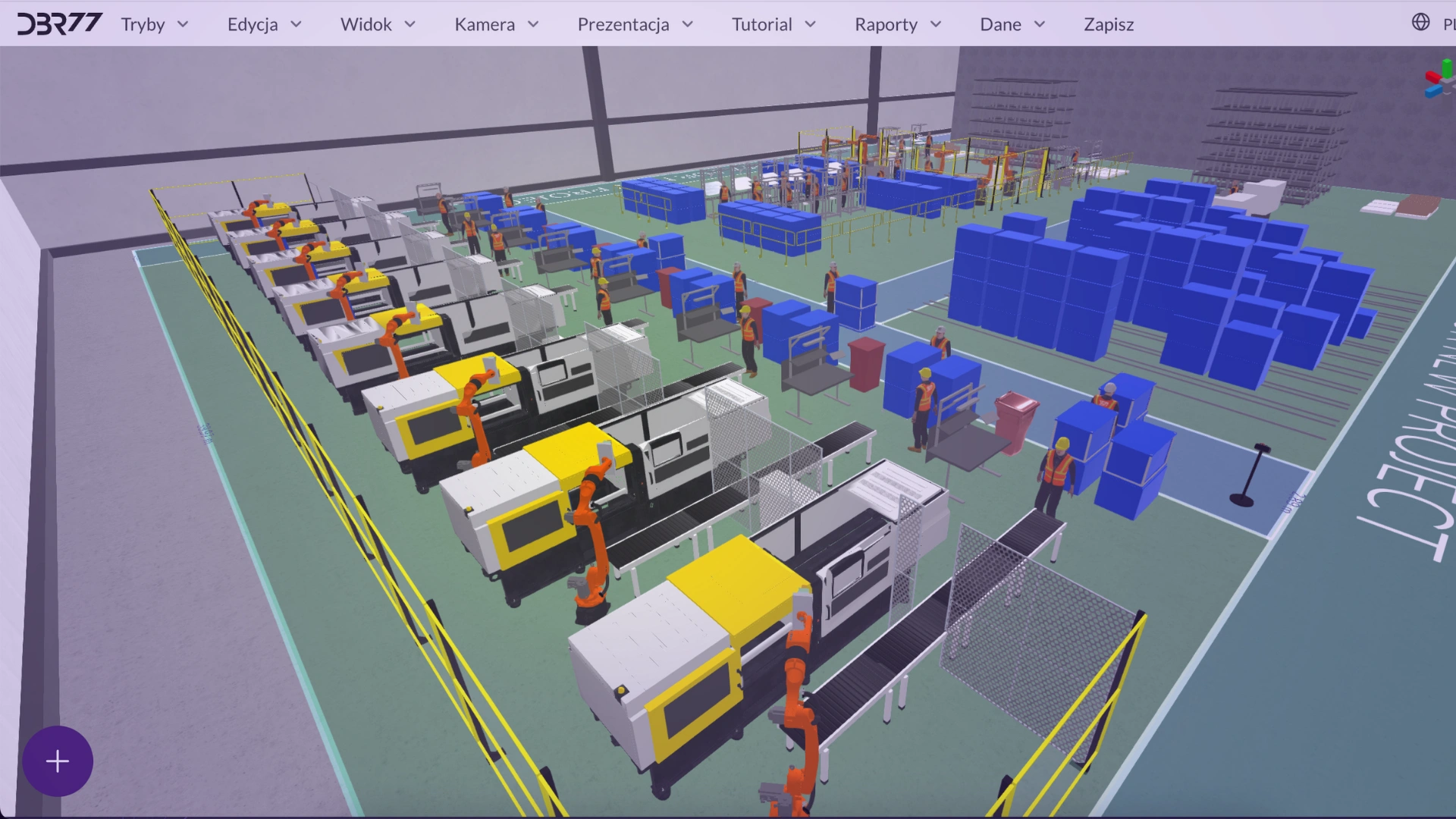

Factory Hall and Layout Design

Work in the 3D Studio can begin by replicating the production space. The user defines the dimensions and shape of the facility and then designs the plant layout, arranging key elements such as communication pathways, storage zones, and production areas to reflect the real factory setup.

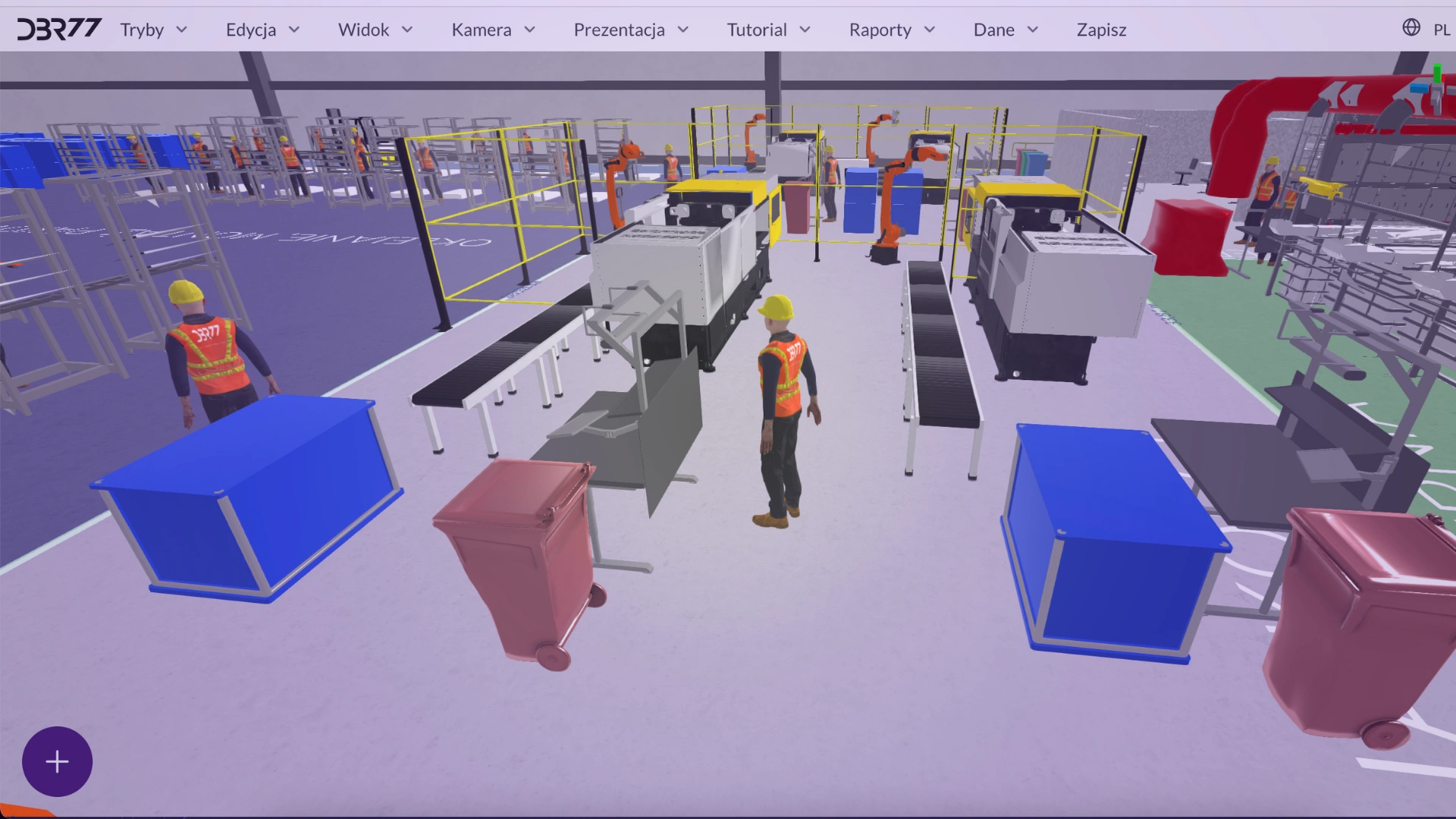

Process and Task Modeling

After designing the layout, the user places 3D models of machines, equipment, and other objects. Then, they define the processes and tasks performed in the facility, assigning them to specific workstations. This allows for a full simulation of workflow dynamics, operational paths, and interactions between production elements.

Why Choose DBR77?

3D Studio DBR77 is a cloud-based platform incorporating a Digital Twin with AI support. It collects IoT data and offers VR/AR integration for precise modeling and visualization. These capabilities streamline decision-making and align production processes with modern facility requirements.

Role in the DBR77 Ecosystem

3D Studio is an integral part of the DBR77 ecosystem, supporting the Digital Twin and Marketplace. By visualizing and simulating production processes, it predicts events, supports data-driven decisions, and optimizes management to enhance the efficiency of digital transformation in production facilities.

News

DBR77 Robotics Closes Seed Investment Round – Launching GO GLOBAL Strategy!

DBR77 Robotics has successfully closed its Seed investment round, with the formal settlement completed on April 17, 2025. In this round, four...

The Fourth Industrial (R)Evolution 2025 is complete!

We have completed the 4th edition of the DBR77 Industrial (R)Evolution 2025 conference! Its keynote was: “The new shape of industry”. As every year,...

DBR77 at the Hannover Messe 2025

Hannover Messe 2025 is all about innovation, robotisation and the future of industry. At this largest trade fair for industry and innovation,...