Key Application Areas of AI in Industry

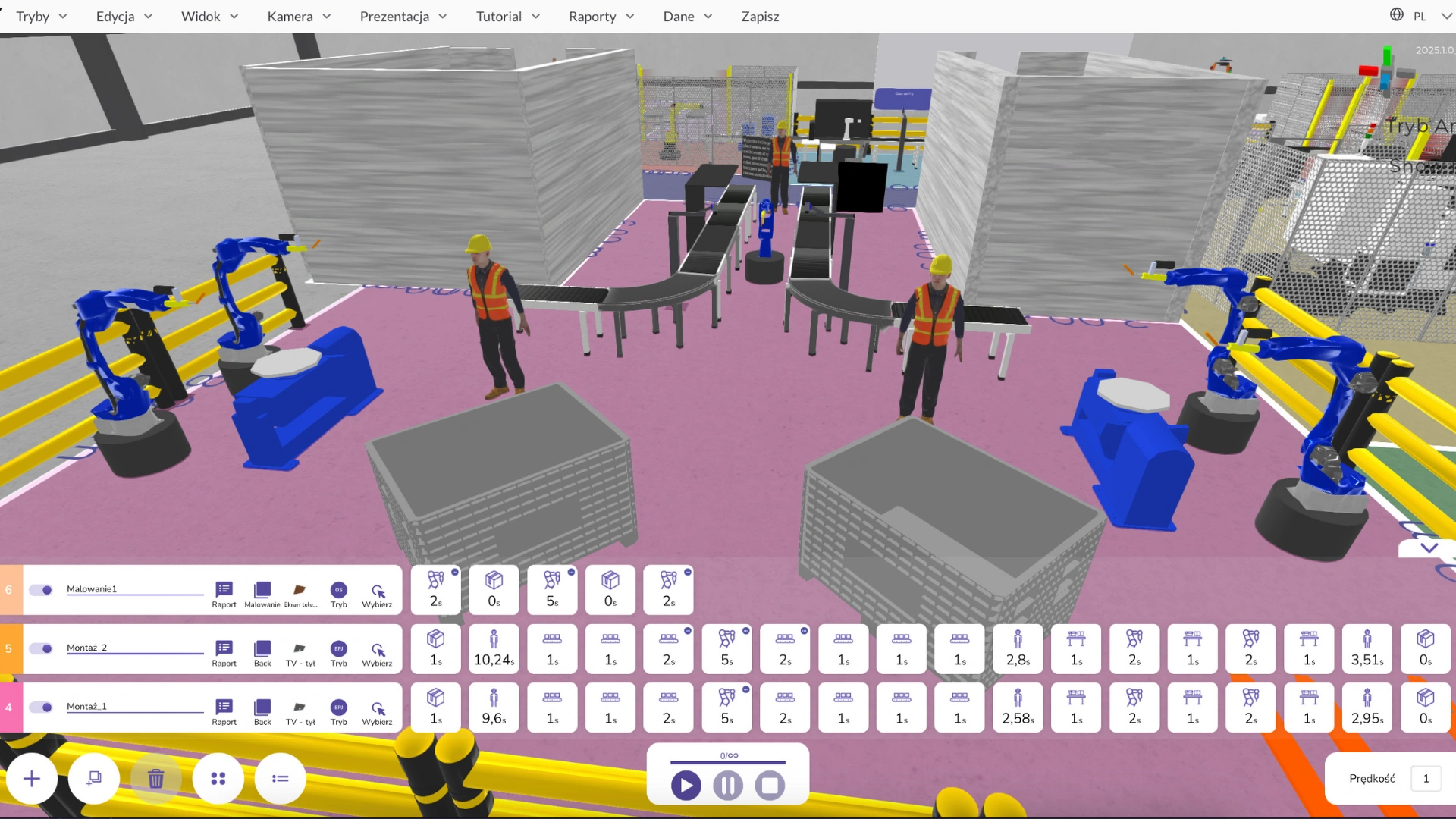

Simulation

AI DBR77 enables automatic simulation of various production scenarios, allowing companies to test solutions without disrupting real operations. This predictive capability helps businesses anticipate potential issues, optimize processes, and minimize risks when implementing new strategies.

Data Interpretation

Equipped with large language models (LLM), the AI on the DBR77 platform interprets complex simulation data to identify key insights and trends. This automated analysis saves time and provides targeted recommendations, focusing on efficiency improvements and identifying automation opportunities.

Support in Decisionmaking

DBR77’s AI utilizes machine learning algorithms trained on historical and synthetic data to deliver precise real-time recommendations. These insights enable managers to make faster, data-driven decisions, improving operational efficiency and flexibility in dynamic production environments.

Technology

Advanced AI Integration

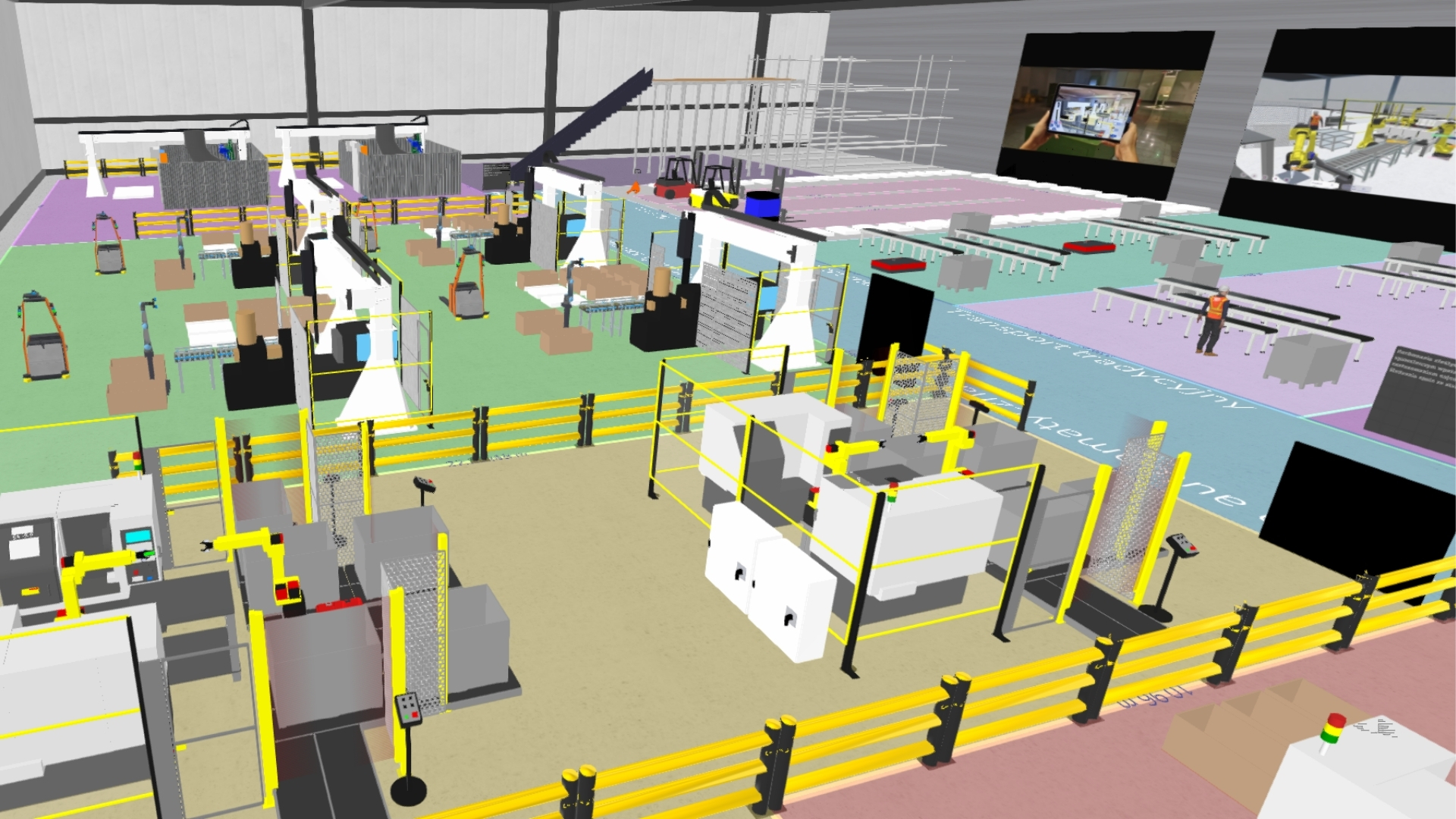

DBR77 incorporates state-of-the-art AI technologies, including scenario simulations and machine learning, to support production process analysis and automation. With large language models (LLM), the platform enables precise forecasting, process optimization, and data-driven decision-making.

Simplicity and Unique Benefits

DBR77’s AI technology is accessible to users without programming knowledge. A user-friendly interface allows anyone to leverage advanced functions, increasing business efficiency. The system focuses on cost savings and process improvements, standing out for its ease of implementation and scalability in industrial production environments.

AI DBR77 functionalities

Scenario Analysis

Using a stochastic digital twin environment, AI DBR77 performs multiple simulations based on various initial assumptions. The system identifies optimal operational strategies, helping organizations prepare for different scenarios. This enables risk identification and process optimization, delivering actionable insights for decision-making.

AI Assistant

Using LLM technology, the AI Assistant supports advanced analysis of visualizations and simulations within the Digital Twin. It enables Lean analysis, factory layout optimization, and automation potential assessment. This accelerates process identification and improvement, increasing efficiency and reducing operational costs.

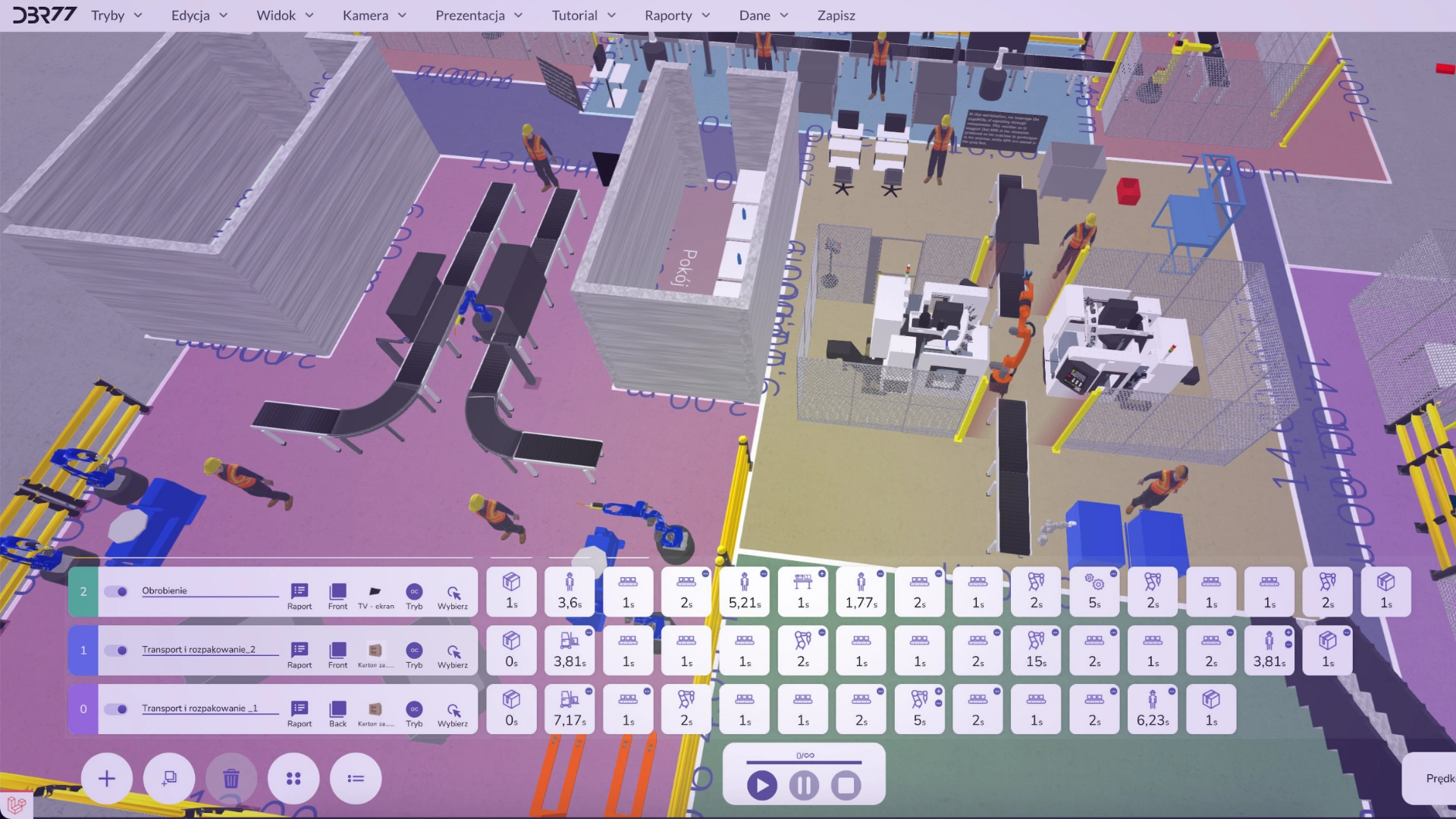

Decision Support with ML Algorithms

DBR77’s machine learning algorithms offer recommendations based on the analysis of current and historical data. Managers can make informed decisions, enhancing operational flexibility. The system allows for quick adaptation to market changes and supports strategic processes, ensuring a competitive advantage.

Workflow of AI DBR77

On the DBR77 platform, different AI tools are used for different purposes, and the way they work depends on the specific challenges they are supposed to address in manufacturing plants. In general, the process of how AI works is as follows:

Data Collection

The first step involves mapping processes by gathering data from machines and production systems. This data forms the foundation for creating a digital model of the facility, enabling precise process analysis and identifying potential optimization areas.

Scenario Simulation

The AI automatically conducts simulations of various scenarios within the Digital Twin, enabling the selection of optimal courses of action. These simulations support the creation of synthetic datasets, which are crucial for analyzing predicted performance and assessing the risks associated with implementing new technological solutions.

Analysis and Interpretation

Based on simulation results, AI generates reports and recommendations to enhance processes. The primary focus is on understanding the impact of changes on operations. This support helps managers design better solutions, minimize risks, and improve overall operational efficiency.

Decision Making

Ultimately, recommendations are provided to managers, who can dynamically implement changes in processes. Algorithms trained on historical and synthetic data support quick and accurate decision-making, allowing production to adapt flexibly to changing market conditions and strategic organizational goals.

Why Choose DBR77?

Comprehensive Optimization

DBR77 provides full control over processes, from data collection to simulation and analysis. The platform identifies bottlenecks, optimizes workflows, and predicts potential problems, enabling organizations to better manage resources, minimize waste, and increase operational efficiency at every stage.

Unique AI-Driven Simulations

DBR77 automatically creates digital twins, enabling precise scenario simulations and outcome predictions. These features support testing solutions before implementation, reducing the risk of errors. The platform provides essential data for informed decision-making, supporting long-term strategies and improving production process efficiency.

Intuitive Access

DBR77 combines advanced technology with ease of use, allowing seamless implementation across various organizations. Even users without technical expertise can take advantage of its advanced features. Thanks to scalability and flexibility, the platform adapts to evolving needs, enabling companies to achieve their operational goals efficiently.

Role in the Ecosystem

AI on the DBR77 platform seamlessly integrates with the Digital Twin and Marketplace modules, accelerating the entire ecosystem’s functionality while making it more intuitive for users. With advanced analytics and IoT integration, AI generates recommendations that significantly enhance decision-making processes, enabling operators and managers to act quickly and effectively.

News

DBR77 Robotics Closes Seed Investment Round – Launching GO GLOBAL Strategy!

DBR77 Robotics has successfully closed its Seed investment round, with the formal settlement completed on April 17, 2025. In this round, four...

The Fourth Industrial (R)Evolution 2025 is complete!

We have completed the 4th edition of the DBR77 Industrial (R)Evolution 2025 conference! Its keynote was: “The new shape of industry”. As every year,...

DBR77 at the Hannover Messe 2025

Hannover Messe 2025 is all about innovation, robotisation and the future of industry. At this largest trade fair for industry and innovation,...