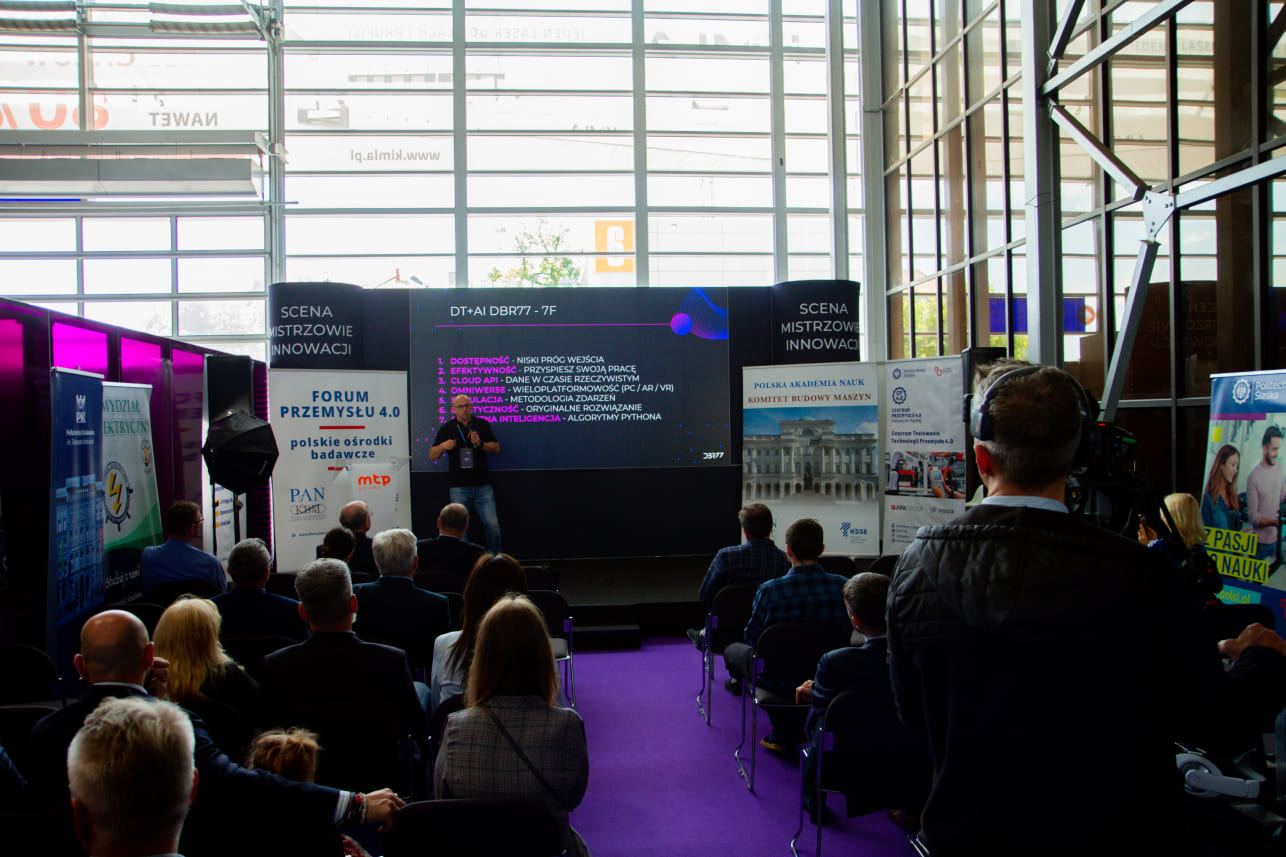

DBR77’s Factory of the Future at ITM 2025

DBR77 at ITM 2025

From 3 to 6 June 2025 at ITM Industry Europe in Poznań, we once again transported visitors to our stand into the fascinating world of tomorrow’s industry. At the heart of Pavilion 4 was the extraordinary Factory of the Future, a place where vision becomes reality and innovation takes shape.

What was waiting for you at Factory of the Future 2025? We focused around three key areas – the pillars of the modern factory:

- People of the Factory of the Future – including women at the centre of industry,

- Managing the Factory of the Future – with Artificial Intelligence in the background,

- Production processes of the Factory of the Future – with a special focus on automation and robotisation.

We invited you to visit this unique space and co-create the Factory of the Future!

SPEAKERS ON THE STAGE OF THE FACTORY OF THE FUTURE

Click on the photo and read a short bio

PILLARS OF THE FACTORY OF THE FUTURE

Day 1 – WOMEN OF THE FUTURE FACTORY

WOMEN OF THE FABRIC OF THE FUTURE: diversity and competence – this was the title of the conference held on the first day of the ITM INDUSTRY EUROPE trade fair (3 June). In the Zone: Factory of the Future DBR77, female experts discussed how team diversity, new competences and bold approaches are shaping the future of industry.

Framework Program – June 3, 2025

Introductory speech: ‘Industry of the Past and Diversity as an Advantage’.

Katarzyna Szwarocka, DBR77

03.06.2025

10:00-11:00

expert panel

Industry leaders and women leaders – what determines success?

Anna Kaczuba, Corning Optical Communications Polska

Monika Malciak, Ficomirrors Polska

Agata Szewc, Alucrom

Beata Praszczyk, SQDA

Katarzyna Marszałkiewicz, DBR77

host: Maciej Wawrzyniak. Schmalz Polska

03.06.2025

11:00-12:00

interview/strong>

Women experts in action

Katarzyna Czachowska, TZMO

Beata Praszczyk, SQDA

host: Maciej Wawrzyniak, Schmalz Polska

03.06.2025

12:00-13:00

workshop

How to effectively build authority in the tech industry? LinkedIn in the industry – practical advice

Agnieszka Wnuk, A&M Consulting Agnieszka Wnuk

03.06.2025

13:00-14:00

panel discussion

Diversity in industry – myth or real advantage?

Joanna Sławińska-Tupaj, WObit

Dr Barbara Pawełko-Czajka, Uniwersytet Dolnośląski DSW

Sylwia Król, SQDA

Kornelia Wójtowicz, SCHULZ INFOPROD

Agnieszka Wnuk, A&M Consulting Agnieszka Wnuk

host: Maciej Wawrzyniak, Schmalz Polska

03.06.2025

14:00-15:00

inspiring talks

‘The industry of the future is us’. – industrial marketing in a new guise.

Julia Mandziak, NIXAL

Marta Pawłowska, Troax

Katarzyna Kozłowska, d. Krispol i Krishome

Paulina Rosińska, Airpress

Katarzyna Szwarocka, DBR77

host: Maciej Wawrzyniak, Schmalz Polska

Day 2 – MANAGING THE FUTURE FACTORY

Our second day at the DBR77 Factory of the Future was dedicated to managing the industry of the future – smart, fast and data-driven. Above all, we highlighted the role of ARTIFICIAL INTELLIGENCE.

We showed how the digital twin of processes, IIoT and artificial intelligence are supporting decision-making, optimising production and building growth strategies for companies.

On our stage and in the exhibition space:

– you saw practical demonstrations of production process management,

– you learnt about solutions from DBR77 technology partners,

– you experienced demonstrations of DBR77’s digital twin in VR/AR,

– you learned how AI is changing business management.

At Factory of the Future, data management is the foundation of competitive advantage, including yours.

Framework Program – June 5, 2025

04.06.2025

10:00-11:00

presentation

AI in practice: how computer vision and LLM are changing everyday manufacturing

Sebastian Drygalski, Flyps

Marcin Biały, Flyps

04.06.2025

11:00-12:00

presentation

No fiction about artificial intelligence – how is it really changing production management?

Examples and effects

Aleksander Faleńczyk, PSI Polska

Michał Żelichowski, PSI Polska

04.06.2025

12:00-13:00

presentation

Data management underpinning the use of AI in industry

Łukasz Grala, TIDK

AI in business

Piotr Wiśniewski, DBR77

Justyna Łaskowska, DBR77

Digital Twin step by step – practical aspects of implementation

Bartłomiej Straszak, DBR77

Mateusz Ochman, DBR77

Day 3 – PRODUCTION IN THE FUTURE FACTORY

The third day of the DBR77 Factory of the Future was dedicated to production processes, because they are what give rhythm to any industrial plant.

On the stand and stage you could see:

– actual robotic workstations from our partners,

– practical applications of automation – from welding to palletising,

– what human-robot collaboration looks like,

– the new possibilities opened up by robotisation, automation and solution integration.

We also showed how the DBR77 marketplace connects companies with integrators and technologies that make a real difference to manufacturing efficiency and flexibility.

Because the future of industry is concrete processes that we can create today!

Our Co-Exhibitors

Click on the bio and read the job description

Click on the logo to see the job description

PROGRAMME – 5 June 2025

Smart factories of the future – IoT in industry

Piotr Wiśniewski, DBR77

Paweł Dera, DBR77

05.06.2025

10:00-11:00

expert panel

Human-Robot Interaction vs Lights-Out Manufacturing: two ways of automation. Safe collaboration or full human-process separation?

Magdalena Morze, Łukasiewicz – Poznański Instytut Technologiczny

Ireneusz Kapler, Troax

Arkadiusz Pietrowiak, Nixal

Karol Habryka, Universal Robots

host: Bartłomiej Straszak

05.06.2025

11:00-11:30

interview

Not just robots – about the role of manipulators in the modern factory

Adam Szlendak, Dalmec Polska

host: Katarzyna Szwarocka

05.06.2025

11:30-12:00

presentation

Cobots on the attack – how collaborative robots are conquering manufacturing facilities

Grzegorz Będkowski (Universal Robots)

05.06.2025

12:00-12:30

presentation

‘But there has never been an accident at our place’ That is, about the risks, consequences and negligence of production automation.

Marcin Lewandowski (Tech-system)

05.06.2025

12:30-13:00

presentation

From Tradition to Innovation: Transforming Welding with the Laser

Kamil Tyrała (IPG Photonics)

05.06.2025

13:00-13:30

presentation

Why will we no longer need MES systems in 2030?

Aleksander Geisler (RAION Software)

05.06.2025

13:30-14:00

presentation

Every second matters. How to combat ‘Muda’ through digitisation

Jacek Urbanowicz (FANUC)

05.06.2025

14:00-15:00

gala

TOP PARTNER DBR77 award ceremony

Our Partners

Ready for the Factory of the Future?

Let’s build it together!

Join us – together let’s show the world what the future of the industry looks like!

Read also on the ITM Industry Europe website:

– Fabryka Przyszłości DBR77

– filary targów ITM

– Kobiety Fabryki Przyszłości

– Agnieszka Wnuk: Kobiet w branży technologicznej będzie więcej

– Cztery dni inspiracji dla przemysłu, nauki i biznesu

Mateusz Ochman

Previous experience: He started his career in IT at Gamesformatic, where he worked on computer game development. He was involved in a project where he co-created advanced, realistic hair physics and was also responsible for designing and programming other gameplay elements. At a later stage of the game’s development, he took on the role of team leader, coordinating the development work and supporting the project’s development. His previous work experience was outside the IT industry in managerial roles, where he was responsible for managing teams and organising work.

Current role at DBR77: He has been with DBR77 since 2023, where he started as a developer. Since 2025, he has been Team Leader of the Unity team, focusing on the development and improvement of the Digital Twin platform. He is responsible for the design and implementation of the Digital Twin’s key functionalities, as well as for organising the team’s work and supporting its development. He is actively involved in the development of cutting-edge technology solutions to support Industry 4.0.

Marcin Lewandowski

Marcin Lewandowski

CEO, TECH-SYSTEM Group

For 17 years, he and his team of engineers have been supporting machine users, designers and constructors in the safe automation of production processes. These activities have resulted in thousands of machine audits and hundreds of educated participants of trainings on the subject of machine safety.

Privately, he is a lover of motorbike and bicycle tourism and high-risk but controlled sports.

Kamil Tyrała

Graduate of the Faculty of Mechanical Engineering at the Silesian University of Technology in the field of Materials Engineering. He has experience in automation, robotics, welding and material science. He is currently Product Manager for the LightWELD system – he is responsible for manual and automated laser welding on the Polish market and in the Baltic States.

Sebastian Drygalski

Sebastian Drygalski – founder and CEO of Flyps.io, a software house developing AI-based products in MedTech and ClimateTech, among other fields. He has been involved in AI for a decade, helping companies turn ambitious visions into working solutions.

He has co-created autonomous shops, AI-powered products (CV or LLM), working with both startups and large companies. He is passionate about innovation – he talks about real-world applications of AI, without marketing hype, focusing on results.

Sebastian Drygalski is the founder and CEO of Flyps.io, a software agency engineering high-tech products that push boundaries in medtech, climatetech, agritech and other areas.

With a decade of experience in AI, he helps companies turn ambitious ideas into scalable tech.

He has co-built autonomous retail systems, dozens of AI-powered products (CVs, LLMs), working with startups and enterprises to bridge the gap between concept and execution. Passionate about innovation, he shares insights on AI’s real-world impact, cutting through the hype to deliver results.

Marcin Biały

Marcin White – Partner at Flyps.io, responsible for business strategy, partnership development and scaling AI solutions. He focuses on linking innovation to business success, helping companies turn technology into real value.

From strategic negotiations to process optimisation to investing in new technologies-Mcin ensures that Flyps.io is always one step ahead of the competition.

Marcin White is a partner at Flyps.io, where he drives business strategy, partnerships, and scaling AI-powered solutions. With a sharp focus on technology-driven growth, he helps startups and enterprises bridge the gap between innovation and business success.

His expertise lies in turning complex tech into real-world value-from AI automation to next-gen digital products. Whether negotiating strategic deals, optimising operations, or navigating tech investments, Marcin ensures Flyps.io stay ahead of the curve.

Jacek Urbanowicz

Several years of experience in industrial robotics – helped make the most advanced robotisation projects in Poland a reality.

Over the past years, he has helped FANUC divisions across Europe to promote IoT products in their markets.

Recently, he returned to his home branch of FANUC to help manufacturers in Poland increase production efficiency through digitisation.

In his spare time, he creates inventions and explores cyber security topics.

Arkadiusz Pietrowiak

I am the founder and CEO of Nixal – a company that transforms manufacturing processes with modern technology. A mechatronics engineer by training and passion, I have always been fascinated by how automation can simplify and streamline our everyday lives.

I taught for 4 years at university, exploring the ins and outs of robotics and automation. Today, I share my knowledge and experience in the Automation in Manufacturing podcast, where I explain the intricacies of my world in an accessible way.

What drives me.

The team – creative minds working together to create extraordinary solutions.

The customer – their satisfaction is our priority and the driving force for continuous improvement.

Challenges – we face new and unique challenges every day that shape our development.

As a hyper-creative innovator (I have the papers to prove it!), I believe that the future of manufacturing lies in smart solutions. At Nixal, we strive to stay ahead of trends and innovate in ways that really matter.

Privately, I am a proud dad of two sons. I love sharing my passion for technology both at work and in my personal life.

Karol Habryka

Karol Habryka – Head of Applications Management EMEA at Universal Robots. Through technical meetings, production audits and workshops, his team helps companies get started with automation – analysing production needs and identifying areas that can be robotised. He is responsible for supporting implementation projects with collaborative robots in the EMEA region, working with partners, sales and marketing teams. He specialises in human-robot interaction issues and practical approaches to automation in real industrial settings.

NG Engineering Sp. z o.o.

NG Engineering Group is a trusted partner in providing cutting-edge engineering services in product development, manufacturing equipment, personnel and software solutions. With specialised companies, including NG Tools, the group supports a broad spectrum of industries, offering innovative technologies to increase efficiency and productivity.

As a key integrator within the group’s structures, NG Tools focuses on the design and production of special-purpose automated machinery for process steps such as machining and assembly, transportation, welding, testing and measurement, as well as team integration (plant engineering). A strong focus on robotics and automation allows NG Tools to provide solutions to support industrial processes and the transformation towards smart manufacturing, increasing productivity and reducing operating costs.

A team of more than 350 engineers and specialists in Poland, Germany and the Czech Republic allows NG Engineering Group to offer high-quality, customised solutions that comply with Industry 4.0 standards. Our experience supports customers in modernising their operations and building competitive advantage through advanced engineering and technology.

Irpark Sp. z o. o.

At IRPARK, we provide state-of-the-art intralogistics solutions based on autonomous mobile robots (AMR), which are revolutionising the way in which material handling is carried out in production plants and warehouses. Our robots autonomously move around the shop floor, avoid obstacles and dynamically adjust routes to ensure process continuity and increase operational efficiency.

We offer end-to-end integration of AMR systems into the customer’s existing environment – from needs analysis, through design, to implementation and service. Our solutions are scalable, secure and easily adaptable, making them an ideal choice for companies seeking to automate material handling without interfering with infrastructure.

At ITM, we will showcase working robots in action – come to our stand where we will demonstrate how AMR can improve your company’s logistics.

Laserion Sp. z o. o.

Laserion was founded by a team of technologists with many years’ experience in designing, implementing and running production processes using high-power lasers.

The company handles hundreds of orders a year, offering services in the field of laser hardening, welding and surfacing, as well as the design and supply of machines in this area.

The use of a robotic laser process allows Laserion to adapt efficiently to different application requirements. It is possible to work with a wide range of materials (from steel to non-ferrous metals) with almost complete freedom of machined geometry and dimensions.

The machines designed and supplied by Laserion are the result of daily engineering practice and cooperation with leading laser manufacturers. Our solutions are characterised by their adaptation to the customer’s needs and are successfully applied in numerous industries, including automotive, machine building, paper and electrical engineering.

Robot Partner Sp. z o. o.

Robot Partner Sp. z o.o. is a dynamically growing engineering company operating in the robotic applications market located in Lublin. Automated welding, palletising and machining machine operation account for 80% of our projects. We also realise non-standard solutions and special machines, built for individual customer needs.

Our product portfolio includes solutions for standard welding stations of the RP WeldBox series, based on welding systems from leading manufacturers, as well as individually designed robotic systems. Our offer is aimed at companies that are looking for process advice and implementation safety at every stage. We provide comprehensive support in terms of installation and commissioning of manufactured solutions, training and after-sales care in terms of service, spare parts and tooling. Our team provides support at every stage of the project from technology development and process testing to comprehensive application implementation and technical operational service.

More than 10 years of experience accumulated during the implementation of 87 key projects, guarantee our ability to carry out all tasks related to the automation and robotisation of production.

RobotSystem Sp. z o. o.

RobotSystem Sp. z o. o. is an engineering company specialising in the realisation of robotised welding stations, welding devices, automats and providing robot and PLC programming services. The many years of experience of the staff allows optimum solutions to be developed, making the company’s offer competitive and the machines supplied presenting a high technical level. Flexibility and focus on customer needs make cooperation a success for contractors.

At the trade fair, the company will present an optimised robotised MIG/MAG welding station for efficient and precise welding of small workpieces. High weld quality is ensured by a FANUC robot in combination with a Kemppi welding machine. Thanks to its well-thought-out design, the stand is highly functional, yet at a very competitive price range and available with short lead times.

We invite you to visit and check out our capabilities!

Lintegra – efficient automation starts here!

At Lintegra, we specialise in designing complete bespoke packaging lines that combine process innovation and care for the planet. At the fair, we present our mission: to revolutionise the logistics industry through technologies that minimise environmental impact, while increasing supply chain efficiency and security.

Our flagship cargo security system, reduces film consumption by up to 40%, while eliminating theft of palletised goods. This not only saves money, but is a real step towards a closed loop economy. We believe that ecology and business can go hand in hand!

At the stand, we are also demonstrating an autonomous robot in the form of a forklift truck, which replaces humans in simple, repetitive tasks. These solutions not only speed up transport processes and minimise errors, but also allow teams to focus on creative challenges. Automation is the future for us – more efficient, safer and environmentally friendly.

We invite you to discover how Lintegra transforms logistics challenges into opportunities by combining the latest technology with the idea of sustainability. Together, let’s build a future where every transport is not only efficient, but also responsible!

ALEKSANDER GEISLER

Aleksander, a senior sales engineer, is a practitioner who precisely manages the technical nuances of MES and machine monitoring system implementations. His involvement includes selling innovative IT solutions to corporate leaders such as Volkswagen, Samsung and Trumpf, as well as Polish family-owned businesses. Aleksander effectively manages projects, covering the areas of training, IT and manufacturing process optimization.

KAROLINA KILIJAŃCZYK

An expert with nearly 20 years of experience in IT consulting, sales and business process consulting. Over the years she has worked with leading organizations, successfully implementing numerous projects in the Data & Analytics area. She specializes in using data to create innovative solutions to support the digital transformation of businesses. Karolina is passionate about sharing her knowledge, helping companies discover the full potential of data to achieve strategic market advantages.

BEATA PRASZCZYK

Graduate of the Department of Environmental Engineering and Power Engineering at the Silesian University of Technology in Gliwice and the Department of Environmental Technology at the International Institute of Higher Education in Zittau (Germany). Associated with the automotive industry since 2000, initially as Supplier Quality Engineer (RDS), Quality Manager (Invenio), Integrated Management System Representative and Director of Infrastructure and Continuous Improvement Department (TRW Automotive). Since 2009, associated with TÜV NORD certification body as Lead Auditor (ISO 9001, ISO/TS16949) and Automotive Manager. Since 2012, associated with SQD Alliance Sp. z o.o. (formerly Team Prevent Poland Sp. z o.o.), where she serves as Director of the QS PACT Department. She cooperates with higher education institutions: EU in Katowice, WSH in Wroclaw and WSIIZ in Rzeszow acting as a content supervisor of postgraduate studies.

PIOTR STANECKI

I believe in a future where people are not afraid of technology – they just understand it and use it to work smarter, not harder.

That’s why I’ve been helping companies discover the potential of collaborative robots for years. I show that cobots are not the future – they are the present that can change the way their teams, processes and entire organisations work.

At Universal Robots, I build relationships that lead to real change – supporting key customers and integrators in the CEE region to create solutions that really matter.

MARTA PAWŁOWSKA

Marta Pawlowska | Marketing Coordinator:

I have over 10 years of experience in B2B marketing, with a specialization in product management, sales strategies and branding. I develop creativity and a fresh perspective through my passion for photography, and find balance in walks in the woods and mountain hikes.

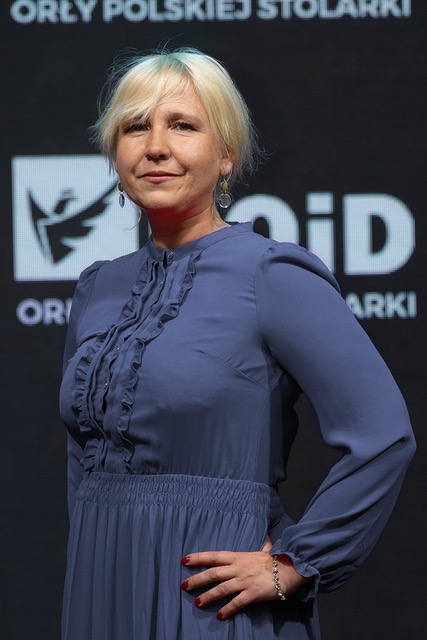

KATARZYNA KOZŁOWSKA

An expert in strategic marketing in the industry, she co-created the development of the Krispol and Krishome brands for more than a decade. She specializes in combining communications, sales and partnerships into a coherent growth strategy, thanks to which marketing in her performance ceases to be an expense and becomes a business driver. She has hundreds of campaigns to her credit, a successful rebranding of the company at a time of market uncertainty, and activities that have established the brand’s position in the B2B and sports sponsorship space. Over the years, she has been a Board Member of the POiD Association and the company’s representative in the Energy Efficient Ready Homes Association. She believes that the modern industry needs not only technology, but also emotion, narrative and trust – built with consistent storytelling. She is a graduate of Poznań University of Economics and Uppsala University.

PAULINA ROSIŃSKA

Paulina Rosinska, Marketing Manager at Airpress:

I’m an automation and robotics engineer by training, but it was marketing that stole my heart piece by piece – until it finally became permanent. For more than 10 years, I have been moving in the world of marketing in the industrial sector, where technology not only drives machines, but also changes the world.

I like challenges. Especially those where you have to dress a complex, technical solution in a clear, interesting and human message. Because even if the product doesn’t shine at first glance – every technology has a story. It just needs to be brought out. And the industry? That’s my environment: fast pace, innovation, real impact and zero room for stagnation.

BARBARA PAWEŁKO-CZAJKA

Dr. Barbara Pawlowko-Czajka

Experienced academic lecturer, trainer, consultant, mentor, researcher. Manager of the Management course at the University of Lower Silesia DSW in Wroclaw. Owner of Positivity training and consulting company. Doctor of jurisprudence, who for years has successfully combined theory and practice.

She specializes in labor law, personal data protection (RODO), employment of foreigners, civil law contracts and social security law. She supports companies, institutions and individuals, showing that even complicated regulations can be explained simply and clearly.

She has many years of experience in conducting trainings, workshops and academic classes. She cooperates with leading training companies, and has also been associated with the Moms’ Club for 10 years, additionally conducting educational workshops for children and teenagers in schools.

She holds a scholarship from the Herder-Institut in Marburg. Within the framework of scientific cooperation, she has carried out research projects and lectures at University College of London, Mykolas Romeris University in Vilnius and Lithuanian University of Educational Sciences, among others.

She believes that law does not have to be boring or bloated – it is possible to talk about it simply, concretely and with humor.

AGATA SZEWC

Experienced leader with more than 20 years of experience in the automotive sector and heavy industry. Specialized in change management, process optimization and implementation of modern quality and safety standards. She is a certified Lean Six Sigma Black Belt, with extensive experience in managing international teams and operational systems digitization and unification projects.

As Managing Director of Alucrom, she is responsible for the company’s strategy, finance and operational development, actively shaping the future of modern industry. She has been honored with the titles of Top Manager 2024 of the Automotive Industry. She is currently developing her competencies in the Executive MBA program at Wroclaw University of Technology.

Committed to promoting the role of women in industry and building strong, inclusive leadership in the manufacturing environment.

KORNELIA WÓJTOWICZ

Kornelia Wójtowicz – Head of Sales at Schulz Infoprod, combines sales and marketing in industrial automation. Strategic approach, partnership relations and synergy of activities are the foundation of her work. Enthusiast of AI and modern tools, looking for the “golden mean” in practice to optimize benefits for the organization.

IRENEUSZ KAPLER

Since 1997, I have been involved in the machinery industry and industrial automation.

I started my adventure with machinery in the technical department of a production plant (meat processing) and after a short time in food processing machinery (Inauen Machinen),

The big automation and robotics jobs are in COMAU and ConTeyor.

From 2015 …until now I take care of the safety of machines and the people working with them, in almost every industrial and manufacturing sector. In a word, In TROAX I managed to combine all my acquired experience and continue to learn new technologies – “making your world SAFE”.

SYLWIA KRÓL

Professionally, she has been in the automotive industry since 2004, where she worked for Tier 1 companies manufacturing fuel lines, steering wheels, car seats, airbag covers, automotive interior trim for brands such as Mercedes, VW, BMW, Volvo, Toyota. She has worked as a quality manager, quality specialist, continuous improvement coordinator, quality management system plenipotentiary, process and system auditor.

She has also worked in the textile industry in the positions of production manager, quality manager and continuous improvement manager.

She has successfully implemented quality management systems in manufacturing plants in Europe and Asia.

She is an ISO 9001 3rd party auditor, trainer and trainer of quality management systems, lecturer at postgraduate courses in quality management. She hosts and contributes to the #Autodrama podcast.

Her professional goal is to further develop in the area of quality management, share knowledge, and support and mentor both professionals and managers in the automotive industry to develop their competencies, increase awareness, and successfully achieve their goals in a demanding and ever-changing industry environment.

JOANNA SŁAWIŃSKA-TUPAJ

She is passionate about combining the world of advanced technology with effective marketing communications in the automation and robotics industry, where she has worked for more than 13 years. As a graduate of International Relations (specializing in Eastern Studies) at Adam Mickiewicz University in Poznan and postgraduate studies in Design Management at SWPS, she uses an interdisciplinary approach to create marketing strategies that effectively translate complex technical solutions into the language of customer benefits. She has authored numerous articles in the trade press on measurement, drive and robotics technology. Her passions are new technologies, innovation and personal development.

GRZEGORZ BĘDKOWSKI

He has been involved in the industrial automation and robotics industry for more than a decade. He gained experience both on the side of manufacturers and integrators of robotic systems, which allows him to comprehensively support companies in optimizing production processes and building competitive advantage. Currently, he is responsible for the development of the market of collaborative robots (cobots) in Polish companies, helping them to effectively implement modern solutions in the field of Industry 4.0.

He graduated from Silesian University of Technology with a degree in Mechatronics and a master’s degree in Business Management.

Privately a father of two children, passionate about new technologies and ADV motorcycles.

ADAM SZLENDAK

Adam Szlendak – Managing Director of Dalmec Poland:

My name is Adam Szlendak and I have been involved in the industrial solutions industry for many years. I manage Dalmec Polska, which specializes in the design and implementation of industrial manipulators. On a daily basis I am responsible for the development of the company’s business in Poland and the Baltic countries. I support customers in the selection of appropriate systems for material handling and improvement of work ergonomics.

In my work I focus on a practical approach – I care that the proposed solutions are not only technically refined, but also realistically respond to the needs of users. I have had the opportunity to work with companies in various industries, such as automotive, household appliances, logistics or food industry, together with teams looking for the best ways to improve production and assembly processes.

ŁUKASZ GRALA

Łukasz Grala – Mentor and futurologist. Promotes knowledge about artificial intelligence. Passionate about finding knowledge in data. Experienced in building analytical solutions, from data warehousing to highly advanced platforms using artificial intelligence. President of TIDK, where on a daily basis he manages a team of experts in data engineering, building analytical platforms and modern data warehouses, Big Data solutions, or AI. Author of podcasts and webinars: “Resistance is futile. Here comes AI!“, ‘Analytics in Business’,” Arena of Architects”.

MICHAŁ ŻELICHOWSKI

Michal Żelichowski, Director of Business Development and Product Management, PSI Poland

Manager with more than 20 years of experience in the area of advanced IT systems for production management, supporting the Lean Management philosophy using APS, MES and IoT/SCADA class solutions. He currently serves as Director of Business Development and Product Management in the area of manufacturing solutions at PSI Polska. With many years of experience in implementing digitization tools in Poland’s largest manufacturing companies, he has a keen understanding of customers’ development needs and goals. Together with project teams, he supports them in effective digitization of processes – without unnecessary waste of resources. In his work, he relies on consulting and a partnership approach, believing that true understanding and a common course of action bring the best results.

ALEKSANDER FALEŃCZYK

Aleksander Faleńczyk, Sales Director, Systems for Production, PSI Polska Sp. z o.o

Has 20 years of experience in sales and implementation of IT solutions for manufacturing companies. He has participated in numerous projects for leading companies in Poland – both in the area of unit and mass production. He specializes in systems supporting the optimization of production processes, such as MES, APS and SCADA. Thanks to his expert knowledge and ability to thoroughly analyze each case, he can accurately identify key areas for improvement, which has translated into real business benefits for many clients.

JULIA MANDZIAK

Julia Mandziak: Marketing Specialist in NIXAL

Industrial marketing expert specialising in building bridges between advanced technology and people. In her daily work, she translates the complex language of automation and robotics into messages that inspire and engage and shows the industry to the world.

With a background in psychology and marketing and experience in the high-tech industry, she proves that a human approach to technology is the key to success in industrial marketing. He wants to show that the industry of the future needs not only engineers, but also specialists to make technology more accessible and understandable.

AGNIESZKA WNUK

Agnieszka Wnuk: B2B marketing consultant and interim marketing manager

Industrial marketing is her passion and her work. She works with companies in various industries such as robotics, automation, steel, wood, furniture, electrical machinery, chemicals, glass, electrical engineering, machine building, food, cosmetics and much more. He combines B2B marketing and sales. He is a B2B marketing consultant and professionally trains with LinkedIn and Sales Navigator. She supports companies in organising their marketing, sets marketing activities through a marketing strategy and plan. She runs ambassador programmes with LinkedIn. Conducts LinkedIn workshops for employees from sales, HR, marketing. Provides training for salespeople, for companies who want to learn and understand LinkedIn.

MACIEJ WAWRZYNIAK

Maciej Wawrzyniak

Key Account Manager | Robotics and Vacuum Automation Expert, Schmalz Polska

Maciej Wawrzyniak is an experienced engineer specialising in the automation of production processes, with a particular focus on vacuum technology and robotic gripping systems.

As an expert at Schmalz Polska, he supports integrators and end users in the design and implementation of tailor-made solutions that increase efficiency and reliability in demanding industrial environments.

A graduate of the Poznan University of Technology, a participant in the Erasmus programme in Barcelona, and a former resident of the state of Michigan in the USA, where he lived and worked for an extended period of time – Maciej brings a broad international perspective and openness to a variety of technological approaches to his work.

Valued for his collaborative partnership approach, he leads projects comprehensively – from needs analysis and technical advice, to component selection, to integration and after-sales support.

Easily translates complex technologies into practical business benefits and finds himself working in teams at the interface of engineering, sales and customer development.

Passionate about travelling and exploring new cultures, an active host of industry events, a theatre actor and a lover of dance – these experiences develop his creativity, interpersonal and stage skills, which he also successfully applies in his professional work.

MAGDALENA MORZE

Magdalena Morze – deals with the subject of human robot interaction (HRI), in the context of researching how people collaborate with robots, whether robots can be workmates, what factors influence effective human-robot collaboration, and whether the way teams work is also changing as robots become more autonomous.

As part of her implementation doctorate, which is being prepared at Poznan University of Technology, she carried out research in companies in Poland, the UK and Australia on methods of managing human-robot teams. She works at ŁUKASIEWICZ – Poznan Institute of Technology, in the Digital Transformation Centre.

She conducted research in Australia as part of a research internship at the University of Technology in Sydney, Centre for Advanced Manufacturing – Australian Cobotics Centre. She has authored scientific and popular science publications in the field of HRI.

Currently, she is creating a research project, funded by the National Science Centre, to study trust in human-robot interaction in the environment of social care homes in Poland.

KATARZYNA CZACHOWSKA

Graduate of MBA studies at the Poznań University of Economics and Georgia State University in Atlanta as well as law studies at the Nicolaus Copernicus University in Toruń. She has been using her experience in law, finance and business processes for 25 years at TZMO Group responsible for the area of communication and public relations.

She is Vice-Chairwoman of the Toruń Women’s Council at the Mayor of Toruń and a member of the Kuyavian-Pomeranian Women’s Council. She organises and leads the Regional Congress of Women in Toruń.

She is a speaker at the Polish Investment and Trade Agency (PAIH) and Welconomy Forum debates where she discusses the topics of global business and wise leadership.

She publishes columns in ‘Nowosci Dziennik Toruński’ (Polska Press) on social, cultural and psychological issues.

She firmly believes in the power of communication based on mutual respect and understanding the needs of others. She believes that conversation is the foundation of successful projects and effective cooperation between people.

MONIKA MALCIAK

Monika Malciak has 17 years of experience in the automotive industry at a strategic and operational level. Her entire professional career has been associated with Ficomirrors Poland, a company that manufactures car mirrors. Currently, Monika is the Director of the Continuous Process Improvement Programme at the Ficosa Group’s Northern European plants. Her work focuses on developing the competence of the teams and improving the production processes, which brings her great satisfaction. Monika loves working with people, observing their development and progress.

In her free time, Monika is passionate about horse riding and spending active time with her family, enjoying every moment. She is an example of a woman who strives for excellence with determination, inspiring others to act and grow in the rapidly changing world of industry.

ANNA KACZUBA

Anna Kaczuba is a graduate of the University of Łódź, where she majored in Marketing and Management. Since 2004, she has been working for Corning Optical Communications Polska Sp. z o.o., where she started her career as an Export and Import Specialist.

Over the years, she has held a number of key management positions within the company, including:

– Head of Import-Export: Responsible for the coordination of processes related to the import and export of goods, ensuring compliance with customs and tax regulations and operational efficiency.

– Logistics Manager: Managed the entire supply chain, optimising logistics and transport processes to increase efficiency and reduce costs.

– Planning Manager: Was responsible for strategic production and procurement planning, ensuring production continuity and timely availability of raw materials.

– Supply Chain Director: Managed the entire supply chain comprehensively, obtained AEO certification, simplified customs and economic procedures and introduced modern technological solutions.

– Production Director: Coordinated all production processes, ensuring they were agile, flexible and of high quality, which resulted in high customer satisfaction.

In her day-to-day activities, Anna Kaczuba supports the strategy of Corning Optical Communications Polska Sp. z o.o., whose overriding goal is to maintain agile and flexible production processes, guaranteeing quality, speed and reliability of deliveries and full customer satisfaction. Thanks to her commitment and professionalism, the company achieves these goals, taking care of the efficiency of operations and constantly striving to optimise processes.

BARTŁOMIEJ STRASZAK

Education: Bartłomiej Straszak holds a master’s degree in nanotechnology engineering from École normale supérieure Paris-Saclay (2010-2012), a master’s degree in materials science from the Wrocław University of Technology (2007-2012) and a master’s degree in production management from the Poznan School of Banking (2014-2015).

Previous experience: Bartholomew’s career includes positions as a senior consultant at McKinsey & Company and as a process and product engineer at Autoneum Holding AG. He has extensive experience in consulting, management strategy and engineering.

Current role at DBR77: Bartlomiej is Executive Director for Central Europe and Wsochnia of DBR77 Robot Platform, responsible for leading the sales and implementation teams in Poland.

KATARZYNA MARSZAŁKIEWICZ

Previous experience:

Expert in the automation and robotisation of manufacturing and warehouse processes in the spirit of Industry 4.0. She is responsible for business development strategy and commercial operations, as well as relationships with key partners and technology providers, including global robot manufacturers and system integrators.

He helps manufacturing plants prepare for digital transformation using technologies such as Digital Twin, IIoT and DRD strategy, supporting companies to optimise processes and increase operational efficiency. She has extensive experience in leading projects for the automotive, aerospace, pharmaceutical, food, metalworking, furniture and logistics industries. For more than 12 years, she was responsible for implementing the financing of large investments in machinery and production lines in industrial plants.

Current role at DBR77: Catherine is Country Commercial Manager at Platform DBR77, where she oversees commercial operations and business development strategies.

She is the creator of the “Dating with Technology” series, in which she shares her knowledge of cutting-edge solutions for industry by inviting experts and market leaders to speak.

PIOTR WIŚNIEWSKI

Education: Piotr Wisniewski holds a PhD in Management from the Poznań University of Economics (2005-2009). He also completed the General Management Program at Harvard Business School (2015-2016) and a Master’s degree in Financial Management at the Nicolaus Copernicus University in Toruń (1996-2001).

Previous experience: Peter has extensive experience in leadership and strategic management. He has served as CEO of the Maflow Group, overseeing plants in multiple countries and leading strategic initiatives that significantly improved operational efficiency and financial performance. He also served as Chairman of the Supervisory Board of Hutmen S.A. and President of the Management Board of Boryszew S.A. Elana Branch in Toruń.

Current role at DBR77: Peter is the founder and global CEO of DBR77, where he leads the company in process automation for various enterprises through innovative digital transformation solutions. He is also a lecturer on digital transformation in MBA programmes and a regular contributor to renowned business magazines.

PAWEŁ DERA

Education: Paweł Dera holds a master’s degree in Electronics and Telecommunications and an engineering degree in Computer Science. Additionally, he completed postgraduate studies in advanced project management. He is currently a PhD student, working on artificial intelligence in intelligent industrial sensors.

Previous experience:

Has over 20 years of experience in the defence industry, reverse logistics and manufacturing. Experienced expert in managing engineering teams. Has worked on management systems, process automation, data analysis and predictive systems. He has spearheaded optimisation projects, dealing with B2B, reporting, RPA and visual inspection. He has also developed support systems for hardware repair.

He has experience in designing systems for electric vehicles, including battery and drive systems. He has led implementation projects related to energy storage and vehicle approval.

Current role at DBR77: Currently in R&D, he focuses on product development, Big Data and IoT technologies.

KATARZYNA SZWAROCKA

She is involved in digital transformation, new technologies and the implementation of innovative solutions in industry. She specialises in development strategy, marketing and financing of innovations, achieving a high success rate in raising funds for research and development projects. She has experience in numerous projects related to digitalisation and Industry 4.0, bringing together the worlds of business, science and institutions.

At DBR77, she is CMO & R&D Specialist, responsible for:

1. marketing strategy – DBR77 brand development, market positioning and digital communication.

2. organisation of key industry events, including the Industrial (R)Evolution Conference – one of the most important events about industry digitisation and automation or DBR77’s presence at ITM Industry Europe, where the latest robotisation and digitalisation solutions are presented.

3 R&D projects in the field of digitisation, automation and AI, supporting innovative implementations in industry.

She is a graduate of the NEXT MBA, among others, where she gained knowledge from global marketing leaders such as Philip Kotler, Seth Godin and Martin Lindstrom. She has also completed numerous courses in AI, Industry 4.0, design thinking and R&D project management, continuously expanding her competences in the area of innovation and technology.

She combines experience in marketing, R&D and implementation strategy, focusing on the real impact of new technologies on the future of industry.

On LinkedIn, she hosts the #BTS (Behind the Scenes) series, in which she reveals the behind-the-scenes of her work and shares her experiences of digital transformation in industry.

JUSTYNA ŁASKOWSKA

Education: Justyna Łaskowska graduated from the Faculty of Law and Administration and completed postgraduate studies in Financial Management and Marketing at the Nicolaus Copernicus University in Toruń. She also completed postgraduate studies in Intellectual Property Management in Business at the Wrocław University of Technology and holds a diploma in IT technician.

Previous experience: Justyna has extensive experience in intellectual property management, project coordination and technology transfer. She was the Director of the Centre for Academic Entrepreneurship and Technology Transfer at Nicolaus Copernicus University, overseeing intellectual property management, entrepreneurship and innovation competencies, knowledge and technology transfer, research team management and fundraising for CPATT activities.

Current role at DBR77: She is responsible for administrative processes as well as sourcing new technology providers and collaborating with universities around the world.

Complete and submit the form or write directly to: katarzyna.szwarocka@dbr77.com

Contact form

By submitting the contact form, you agree to be contacted by telephone to handle this application. You agree to receive commercial information by means of electronic communication sent by www.dbr77.com and to the use of email communication for marketing purposes (Privacy Policy).