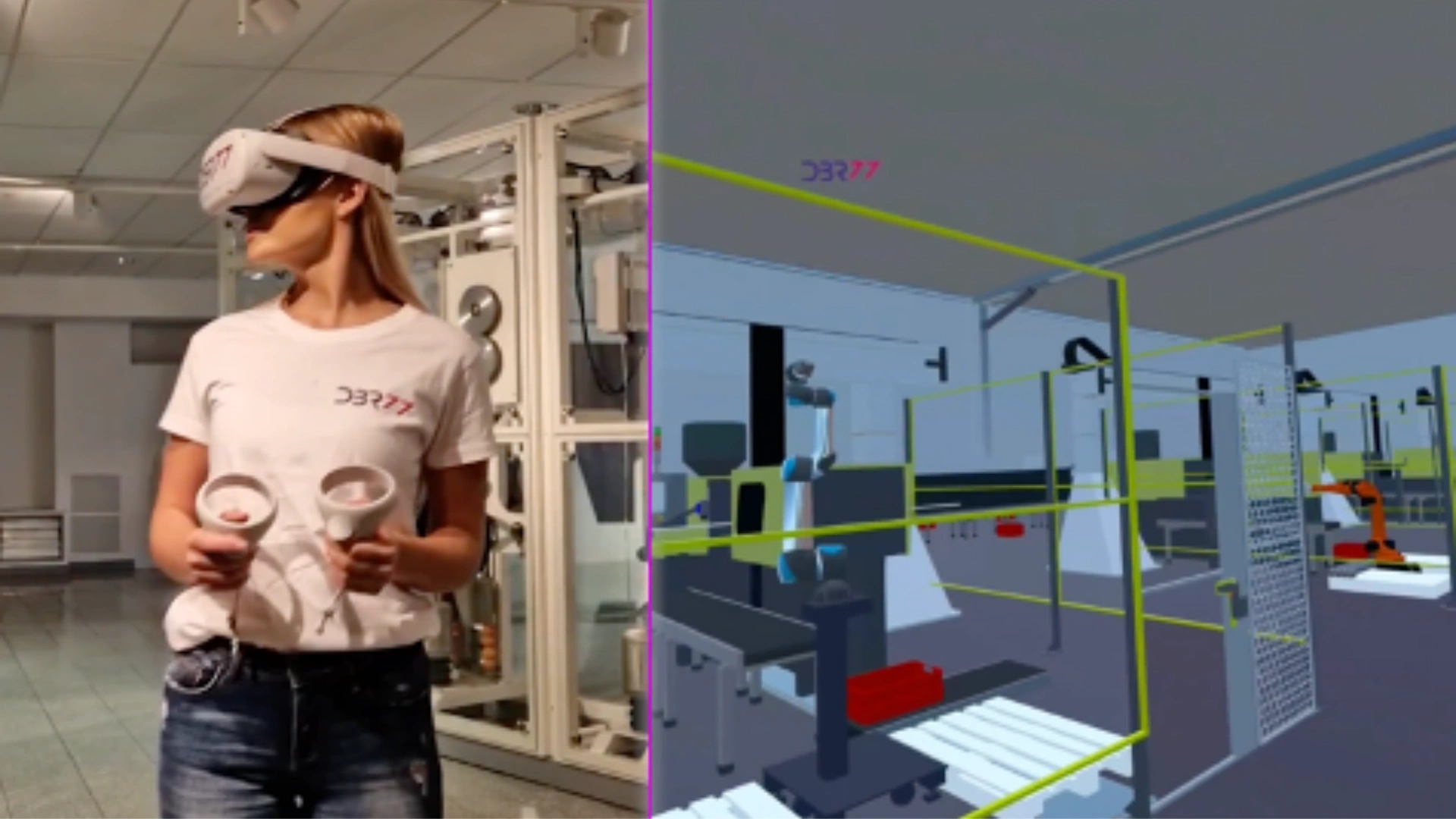

VR - Virtual Reality

Virtual Reality immerses users into a virtual environment using specialized headsets. DBR77’s VR functionality supports detailed visualizations of industrial processes, offering realistic representations of investments and enhancing project understanding before implementation, thereby minimizing risk.

AR - Augmented Reality

AR enhances the real world with computer-generated 3D models and text. In DBR77, AR integrates digital models with real spaces, facilitating interactive planning and investment visualization. Users can see how machines or production lines will look and operate before implementation.

Core Principles of Technology Development

The AR/VR technology in DBR77 is designed to complement the digital twin and marketplace by enabling users to realistically visualize their production projects and analyze machinery and equipment. Integrated with the 3D studio, all input data can be visualized in AR/VR, supporting precise planning and purchasing decisions.

Features

Full Immersion in VR

VR provides complete immersion in production or warehouse spaces. With realistic dimensions and proportions, users gain a comprehensive understanding of layouts and object functionality within the virtual environment. This feature supports better planning and minimizes the risk of errors before implementing changes in real facilities.

Real-Condition Analysis with AR

AR allows for the visualization of designed objects within an existing factory space. This helps users assess how components fit into the infrastructure, enabling efficient implementation planning. The tool minimizes design errors and supports better space management within the facility.

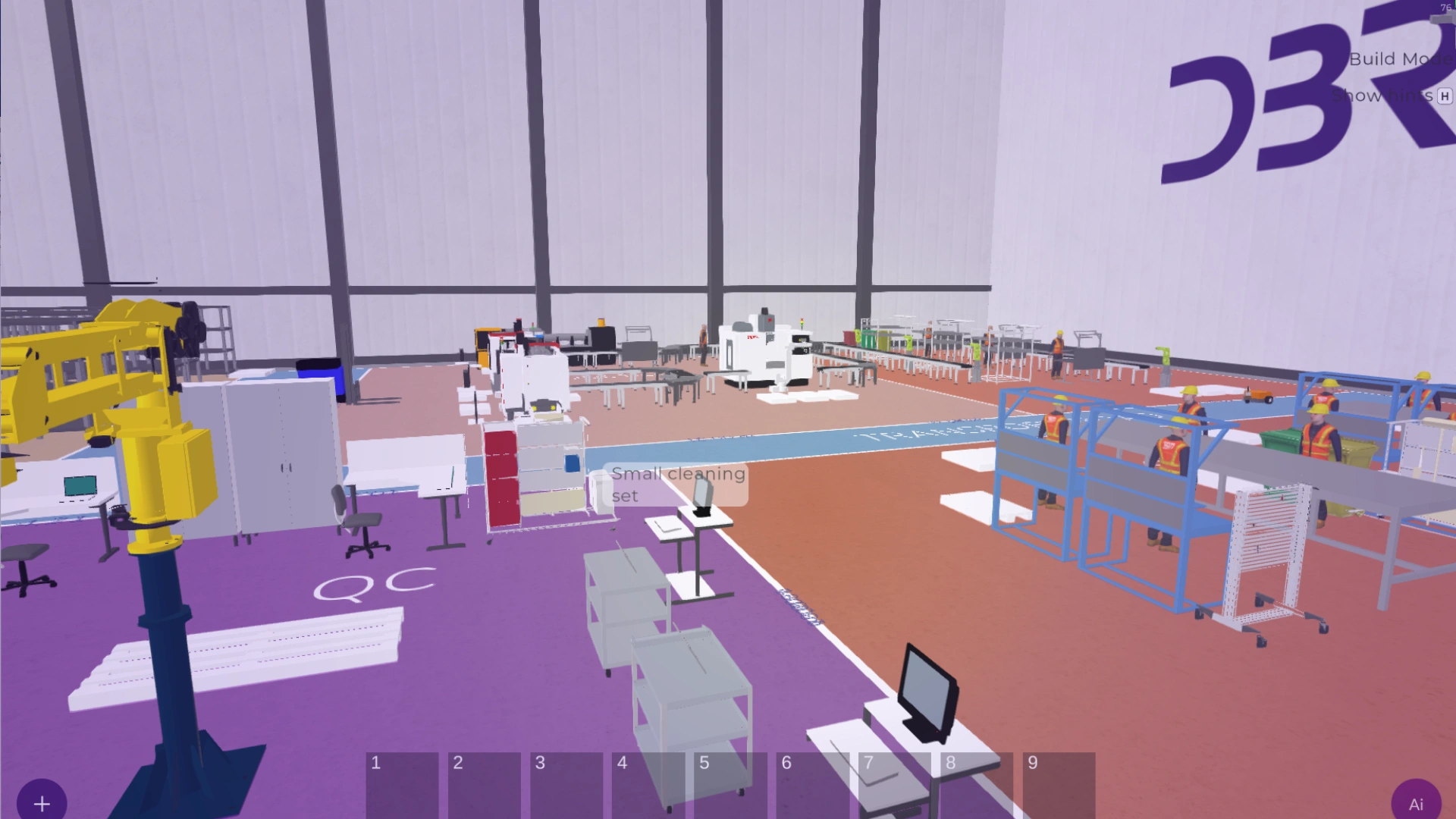

Machine and Showroom Presentation

Creating virtual showrooms enables the presentation of machines and products in full functionality. Specifications, videos, and pricing information can be added, enhancing both the purchasing and educational processes. This approach simplifies decision-making for clients and increases engagement in sales and project discussions.

How It Works

Scene Creation in 3D Studio

Begin by designing the space in the 3D studio, mapping out machines, equipment, and other elements. Users define the layout and dimensions of the production area, ensuring real-world proportions. This method facilitates accurate equipment placement and optimized space utilization.

VR Visualization

To view a scene in VR, users must wear VR goggles, install the DBR77 application, and enter the scene number. Once inside, users can freely navigate the virtual space, analyzing object details in full scale. This feature supports realistic design and the identification of potential issues.

AR Visualization

In AR, users utilize the DBR77 application on a tablet or smartphone to visualize objects in real space. By entering a scene number, models can be placed within the factory, allowing users to check their compatibility with the environment. This solution provides a better understanding of how components will function in practice.

Why Choose DBR77?

Omniverse Integration

All environments are connected into a comprehensive digital twin. DBR77 integrates VR, AR, and 3D modeling technologies, enabling full visualization of processes and spaces. Easy integration with existing infrastructure makes it the ideal tool for precise planning and operational analysis.

The Perfect Sales Tool

DBR77 enables realistic 3D space presentations for sales purposes. VR/AR visualizations help potential customers better understand the value of proposed solutions. This tool enhances negotiation effectiveness and fosters trust through interactive presentations.

Role in the Ecosystem

The AR/VR technology is a critical complement to the 3D studio on the DBR77 platform, supporting the digital twin and marketplace. It allows suppliers and integrators to create immersive experiences that simplify purchasing decisions and add value to the sales process.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...