The Problem We Solve

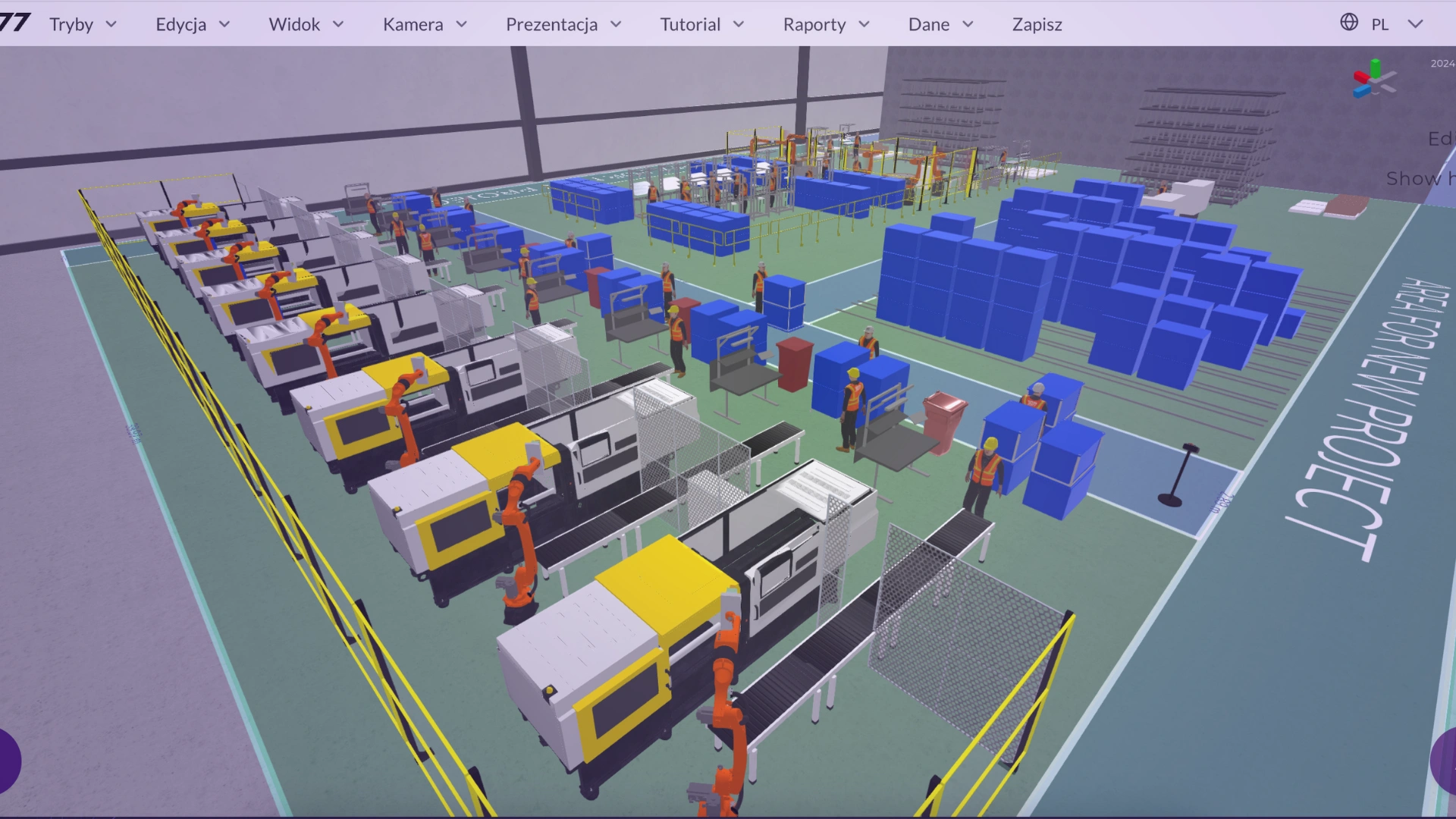

Planning and designing production facilities and logistics centers pose significant challenges, especially when building new facilities, modifying existing layouts, or purchasing new machinery. Without the right tools, companies risk planning errors that can lead to reduced efficiency and costly downtime. DBR77 helps companies design efficient production and logistics layouts, reducing risks and supporting process optimization.

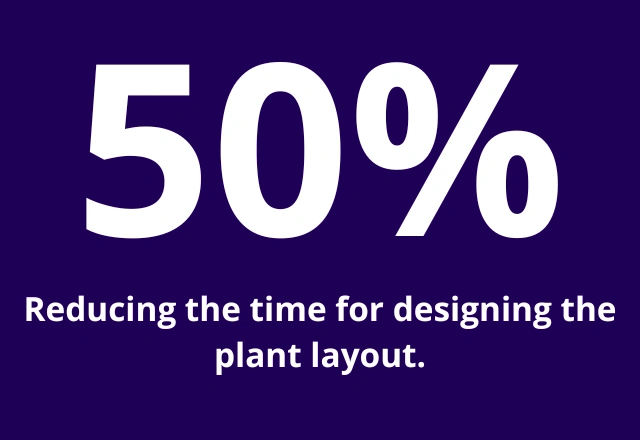

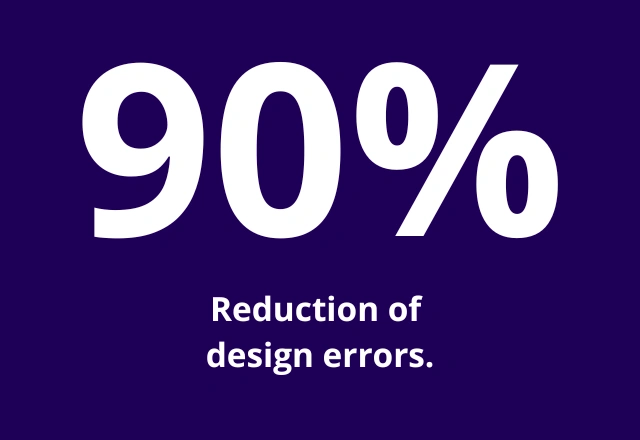

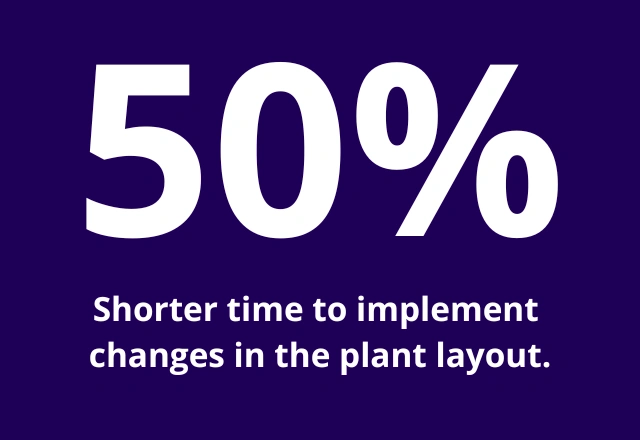

Results in Numbers

DBR77 Solutions

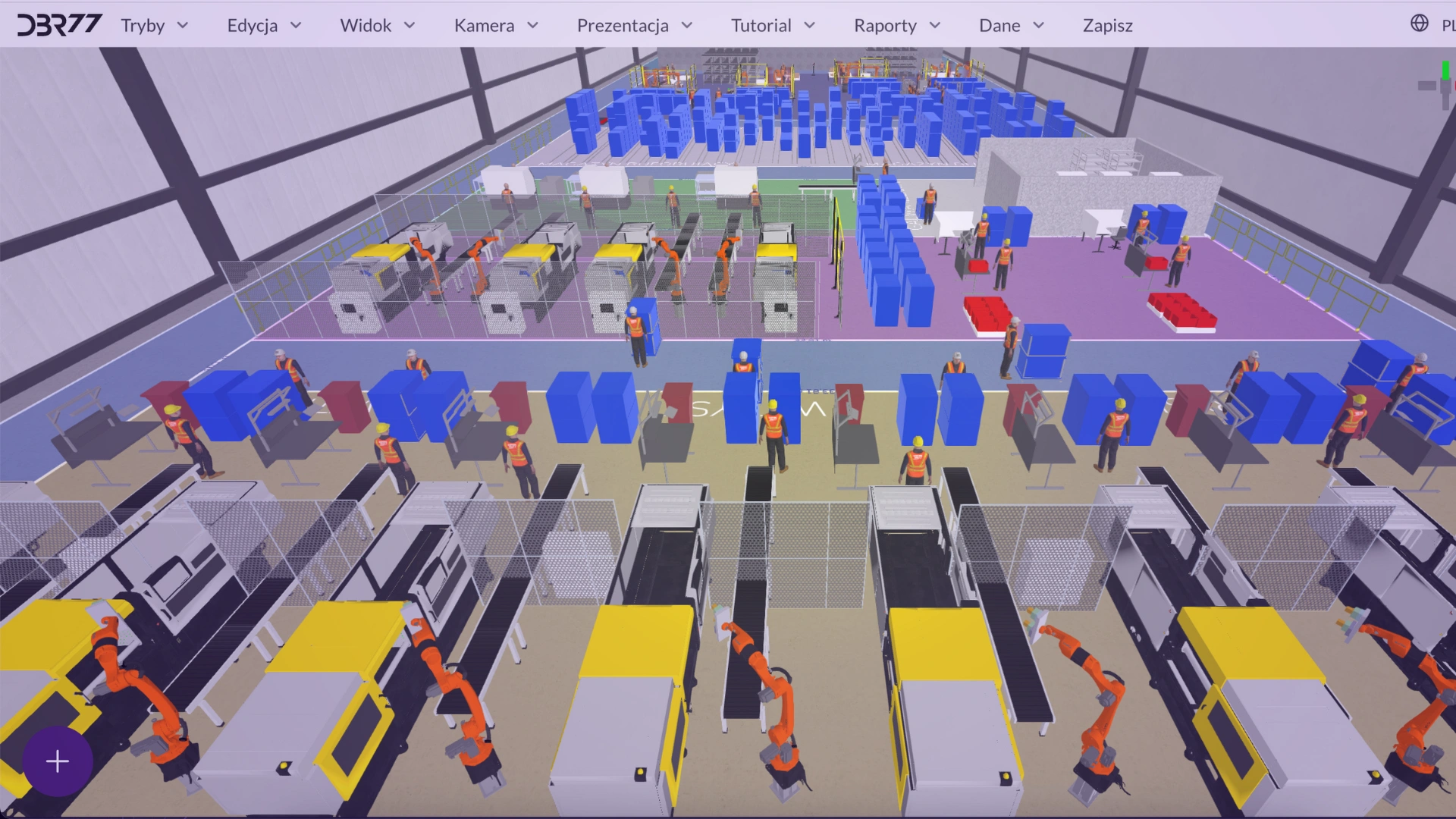

DBR77 provides comprehensive support for designing production facilities, offering dynamic 3D project analysis that far surpasses standard 2D tools. Our solution enables:

1. Creating Digital Models of Facilities

Accurately replicating production and logistics spaces in a virtual environment. Realistic models help companies effectively plan spatial layouts, avoiding issues in later stages.

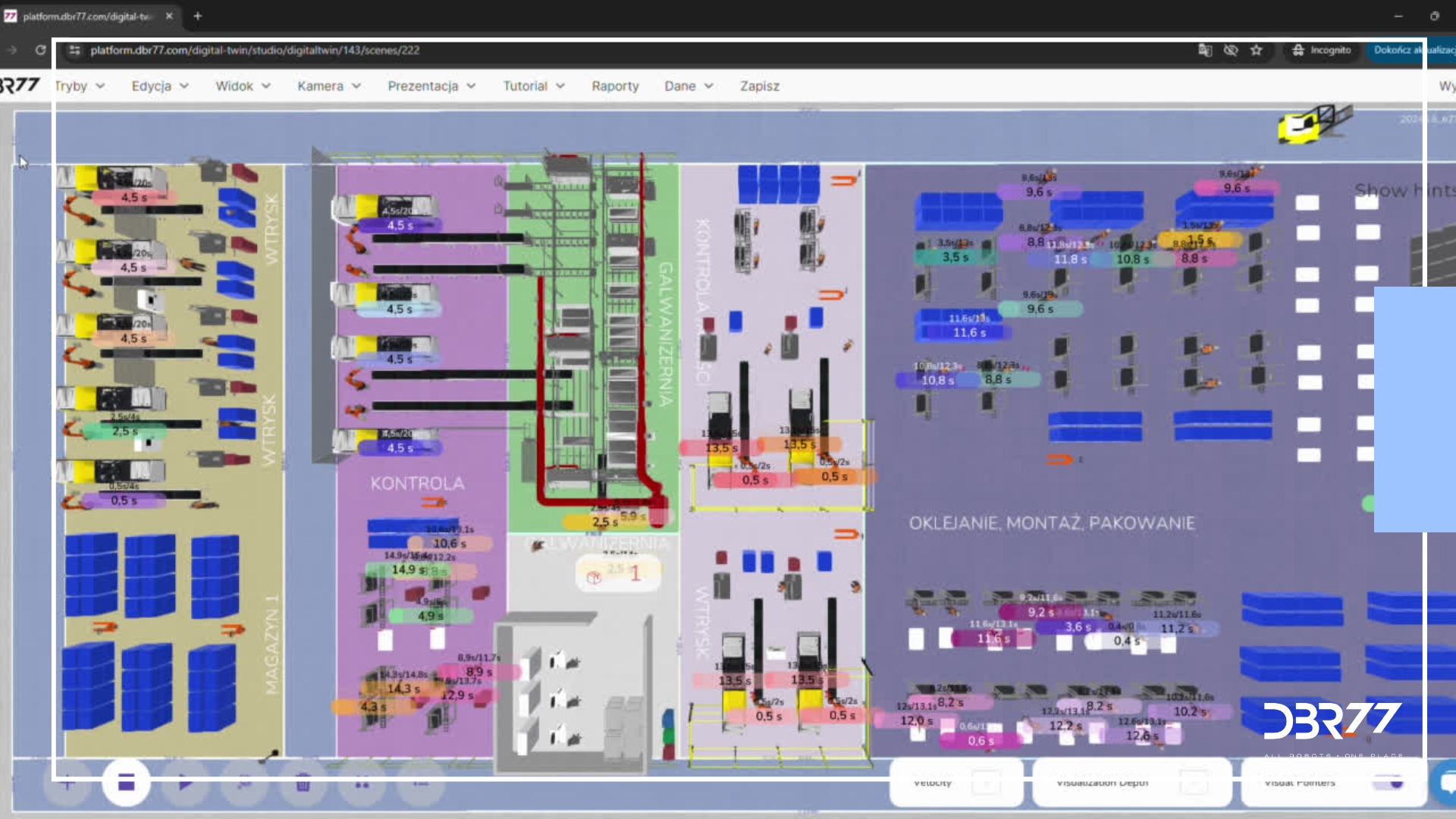

2. Analysis of Material Flows and Work Processes

The simulation of various scenarios enables efficient planning of production spaces. Through analysis, bottlenecks can be identified and eliminated, increasing operational efficiency and optimizing material flow.

3. Analysis of Production Capacity

Detailed capacity analyses allow for better resource management and more precise workload planning. The tool helps adjust production processes to changing demand, increasing flexibility and efficiency in the facility.

4. Planning the Purchase and Placement of Machines

Simulations analyze the impact of new machines on existing production processes. This minimizes the risk of poor investment decisions and maximizes the efficiency of integrating new equipment into the production facility.

Advanced Technologies

DBR77 utilizes Digital Twin technology and 3D tools for facility layout simulation and visualization. The platform enables precise replication of production spaces, and virtual simulations help identify optimal solutions. By integrating IoT and AI, users can perform advanced real-time data analyses, supporting accurate planning and operational optimization.

Why Choose DBR77?

Ease of Use and Layout Design

DBR77 requires only an hour of training. Its intuitive interface allows for quick design of production lines and facilities. The platform supports all design stages, from modeling to production space optimization.

3D Visualization and Cloud-Based Simulations

The tool enables a realistic representation of the production environment. Cloud accessibility facilitates flexible collaboration, remote planning, and quick access from anywhere, improving decision-making processes.

Optimization of Investment Costs

Analyzing the impact of new machines and layouts helps in precise budget planning. DBR77 minimizes the risk of incorrect investments, supporting optimal resource and production process management.

Case studies

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...