The Problem We Solve

Modern industrial and logistics companies face challenges such as rising operational costs, a shortage of skilled labor, and the need for rapid adaptation to changing market conditions. DBR77 enables effective digitization of processes, helping businesses transition seamlessly to automation and robotics-based solutions, ensuring long-term stability and a competitive edge.

Results in Numbers

DBR77 Solutions

DBR77 provides a comprehensive set of actions aimed at improving work efficiency and reducing operational costs. Through its holistic approach to digital transformation, DBR77 supports businesses in optimizing production and intralogistics processes. The key implementation steps include:

1. Implementation of an Automatic Measurement System

This solution enables the precise determination of standard times for all operations within a facility. For example, in electronic module assembly, standardization has led to a 20% increase in efficiency. Additionally, it allows for the calculation of efficiency coefficients (OEE), providing a complete picture of process performance and identifying areas that require improvement.

2. Optimization of Production Area Organization

By utilizing a digital twin, it is possible to create an optimal factory layout and balance tasks on production lines. This process typically takes 4 to 6 weeks and requires digital tools, but it offers significant precision and the ability to simulate various scenarios. It improves workflow, minimizes downtime, and increases overall production efficiency.

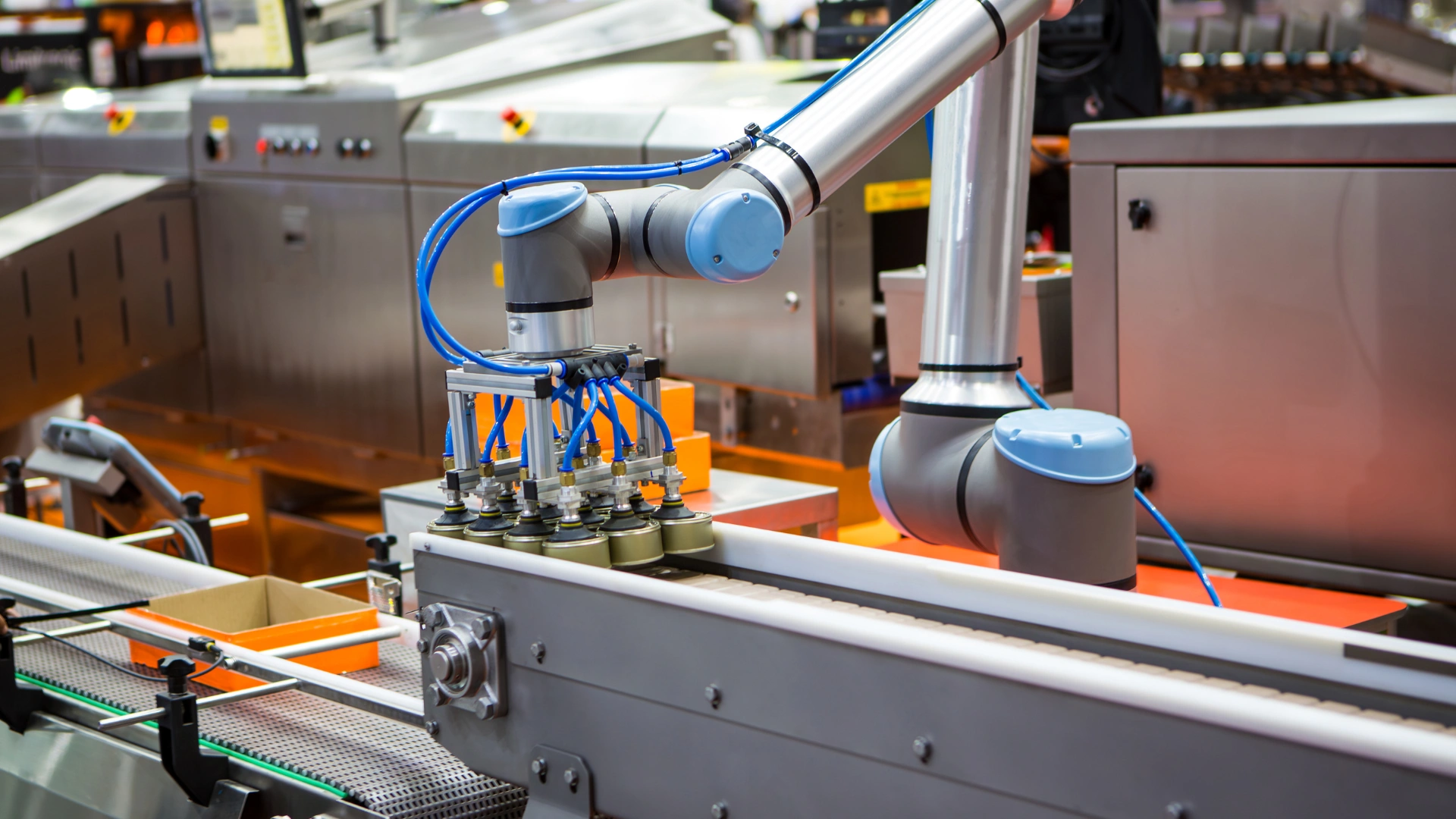

3. Automation of Production and Intralogistics Tasks

Production processes are executed with less human intervention, significantly increasing productivity. Automation reduces operational costs, eliminates human errors, and allows for more flexible resource management. The most commonly automated tasks include internal transport, packaging, sorting, and assembly line operations, which accelerate processes and enhance their accuracy.

Integrated Solutions for Industry

DBR77 offers a range of interconnected solutions that create a comprehensive digital transformation environment. From precise IoT measurements and advanced Digital Twin technology to an extensive Marketplace platform, DBR77 provides exceptional tools to support every stage of digital transformation. VR and AR technologies allow for accurate process replication, while artificial intelligence facilitates optimal operational decisions, enhancing efficiency and flexibility.

Why Choose DBR77?

DBR77 Benefits for Industry:

DBR77, developed by production management experts, addresses specific industrial challenges such as eliminating downtime, optimizing material flow, and reducing costs associated with manual logistics operations. Its flexible IoT and Digital Twin technologies adapt to any type of production, supporting businesses of all sizes in optimizing processes and boosting efficiency.

Access to Global Technologies:

The DBR77 platform allows businesses to select the best robots and tools from leading suppliers, supporting digital transformation efforts. Advanced AI-driven data analyses facilitate quick, optimal production decisions, such as analyzing production line efficiency, predicting machine failures, and optimizing inventory management, enhancing competitiveness and streamlining processes in dynamic industrial environments.

Business Case

DBR77 delivers tangible benefits to the industrial sector, supporting digital transformation at every stage of the production process. Example applications include:

1.Operational Cost Reduction

With automation and IoT, companies can reduce labor and energy costs while boosting productivity.

2. Process Optimization

The Digital Twin enables detailed analysis of production layouts, allowing for precise planning and reducing downtime and errors.

3. Faster Innovation Implementation

DBR77 shortens the time required to implement new technologies by 50%, enabling faster adaptation to changing market needs.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...