The Problem We Solve

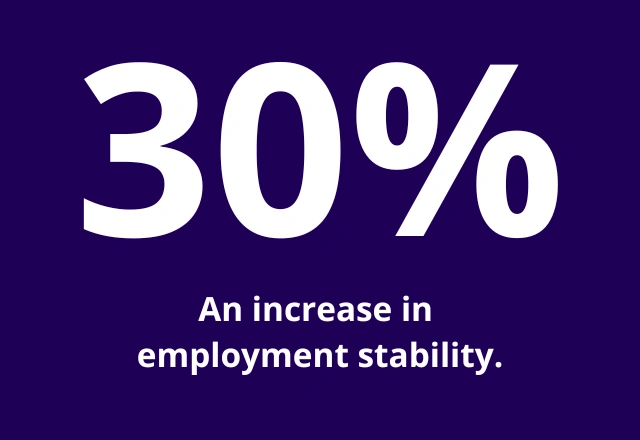

HR managers in manufacturing and logistics face challenges in ensuring stable working conditions and fostering the development of employees’ digital competencies. Increasing efficiency and automating processes are crucial for profitability, which directly impacts job stability. The lack of technology that supports the development of digital skills and improves operational efficiency limits a company’s competitiveness.

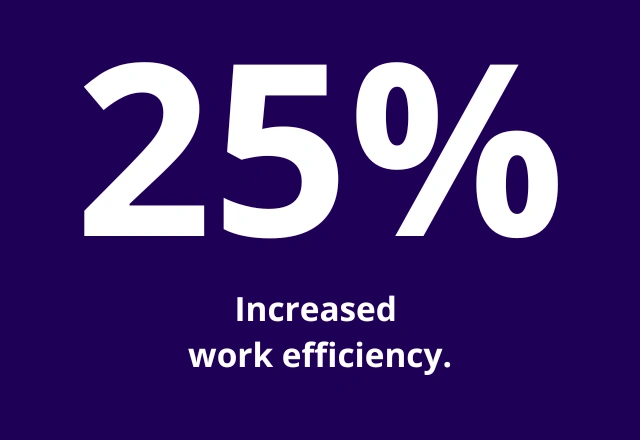

Results in Numbers

DBR77 Solutions

DBR77 offers support to HR Managers, supporting employee development and company stability:

1. Improving Working Conditions

Optimized processes and AI Assistant support create safer, more ergonomic work environments. Automation eliminates the most strenuous tasks, reducing accident risks. Comfortable workstations and better time management enhance employee satisfaction and engagement, leading to increased productivity.

2. Development of Digital Skills

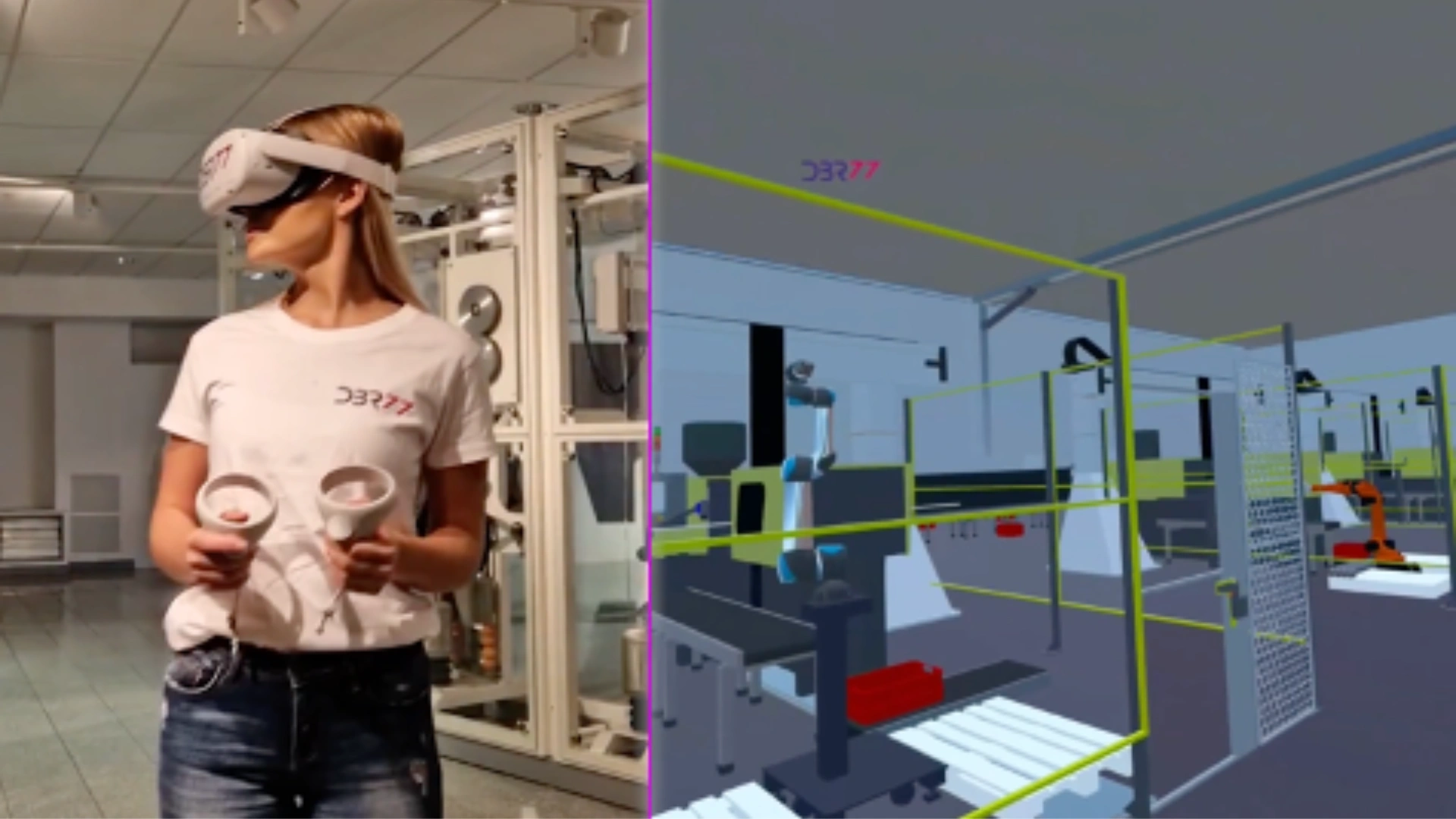

The digital twin and VR/AR technologies enable employees to develop digital competencies, preparing them for technological transformation. Through advanced training and simulations in a virtual environment, employees can gain practical experience without operational risks. The DBR77 AI Assistant supports learning by providing easy access to knowledge and facilitating adaptation to modern tools.

3. Improvement of Working Conditions

By optimizing processes and leveraging the DBR77 AI Assistant, employees can work in safer and more ergonomic conditions. Automation eliminates the most strenuous tasks, reducing the risk of workplace accidents. Comfortable workstations and better time management enhance employee satisfaction and engagement, ultimately boosting productivity.

Technology

DBR77 is a comprehensive platform consisting of three modules: data collection (IoT), digital twin, and automation (Marketplace). Operating in a cloud-based environment, VR/AR technology and the AI Assistant enhance employee digital competencies and boost the company’s operational efficiency.

Why Choose DBR77?

1. Ease of Implementation and Ergonomics

DBR77 offers a low entry barrier, allowing employees to quickly master new technologies. The platform’s intuitive tools ensure efficient solution deployment, increasing productivity and satisfaction. The digital twin optimizes processes and workplace layouts, ensuring safe conditions that positively impact health and team comfort.

2. Attracting Talent and Efficient Onboarding

Modern DBR77 technologies, such as the digital twin and VR/AR, attract young professionals by offering an innovative work environment. Realistic simulations streamline the onboarding process, boosting newcomers’ confidence and helping them quickly adapt to new tasks. This support strengthens teams in dynamic organizations.

Case studies

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...