The Problem We Solve

Industrial companies often struggle with a lack of accurate and up-to-date data essential for optimizing processes and making real-time decisions. Collecting data from machines and production processes is challenging, costly, and often inefficient without the right tools for analysis. DBR77 helps companies overcome these barriers by offering integrated solutions for data collection and analysis, enabling process optimization and performance improvement.

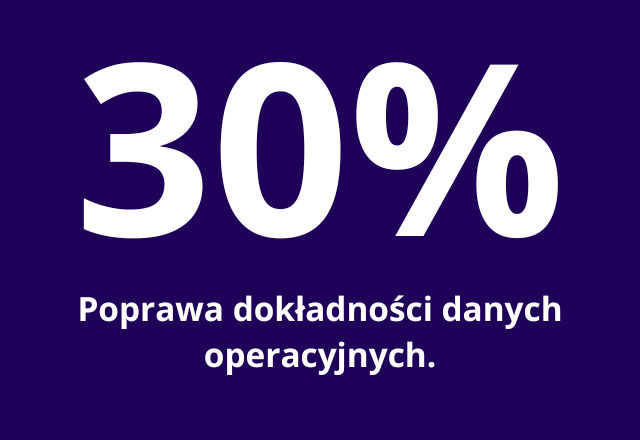

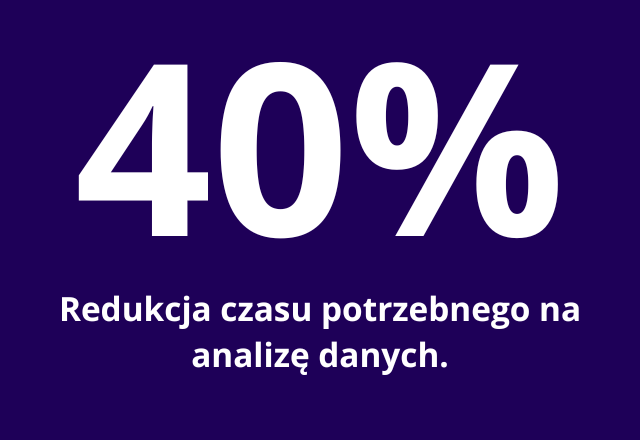

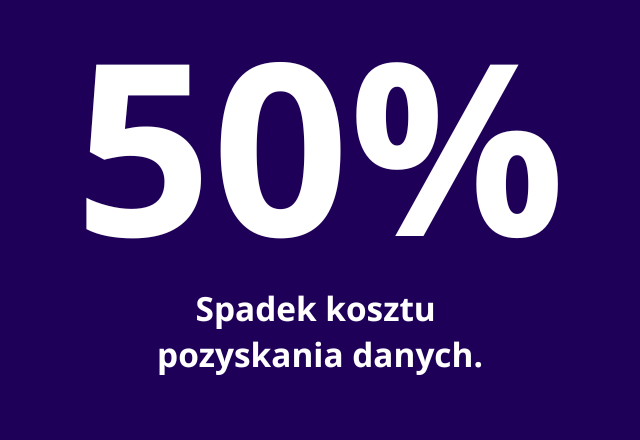

Results in Numbers

DBR77 Solutions

The DBR77 platform offers comprehensive operational data collection tools that enable:

Setting Standards for Operation Times

Automatic data collection precisely measures the execution time of each production stage. This facilitates process standardization, reduces deviations, and improves resource management and operational planning.

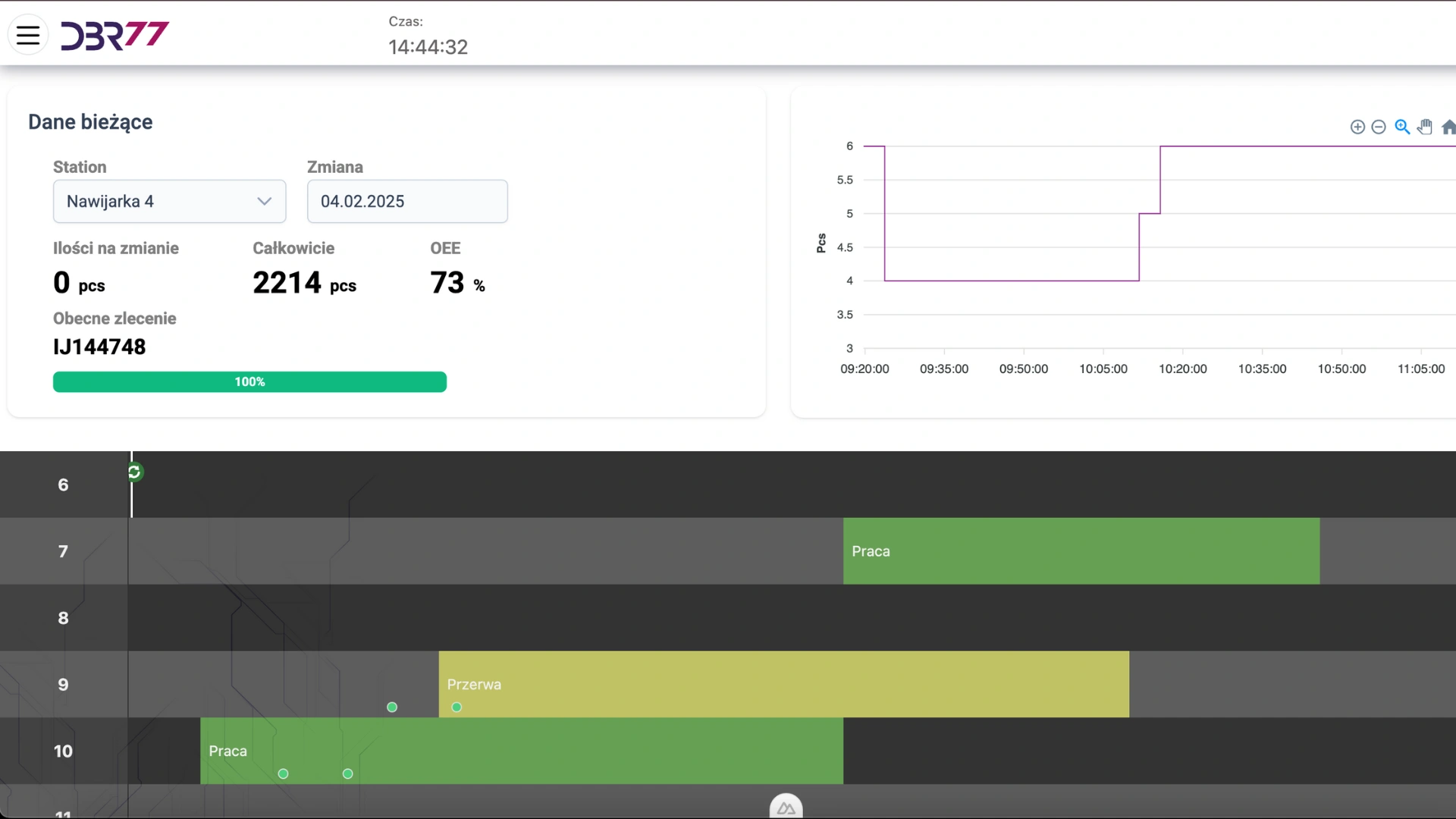

Increasing Process Efficiency

Visualization of results at workstations enables immediate response to problems. Real-time monitoring helps minimize micro-downtime, eliminate waste, and effectively enhance the overall operational efficiency of the production facility.

Production Capacity and Value Stream Analysis

Operational data allows for the identification of bottlenecks and areas needing improvement. Optimizing the flow of materials and resources increases work efficiency, reduces order fulfillment time, and enhances production performance.

Data Collection for Advanced Analysis

The platform integrates real-time data, which can be analyzed using AI and the Digital Twin. This enables not only the optimization of current processes but also forecasting future needs and planning strategic actions.

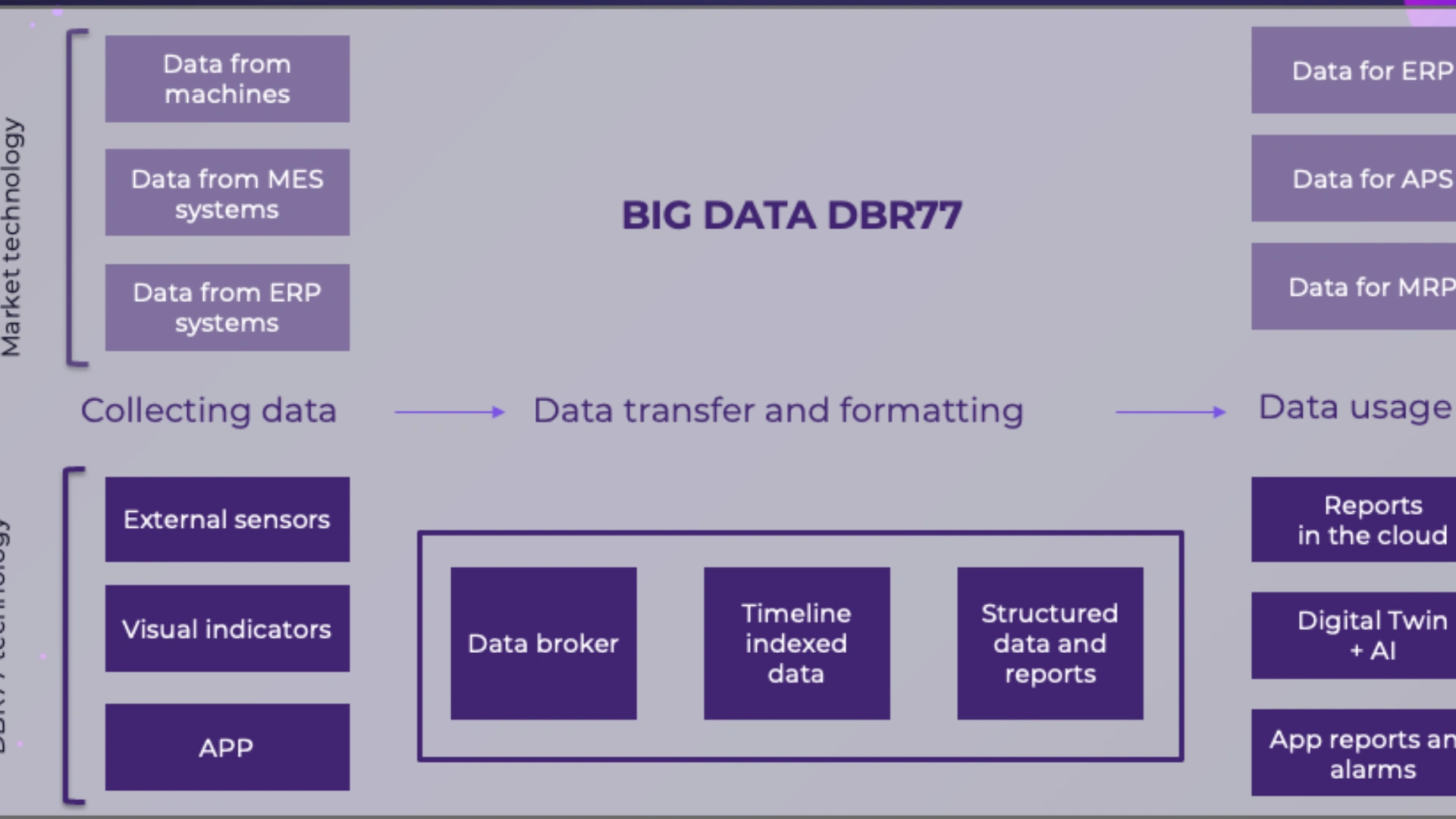

Technology

The DBR77 platform utilizes IoT technologies for precise monitoring of machines and processes. Dedicated systems collect data from production lines to support operational optimization. AI algorithms analyze data in real time, facilitating rapid decision-making and improving production facility efficiency.

Why Choose DBR77?

Comprehensive Data Collection and Analysis Solution

DBR77 provides complete visibility into operations by collecting data from every stage of the process. It enables precise performance measurement, result analysis, and report generation to support informed operational decision-making.

Flexibility and Integration

DBR77 integrates with various production devices and systems, adapting to the specific needs of each facility. Quick implementation ensures immediate access to real-time data, streamlining management and increasing process efficiency.

Data-Driven Decision-Making Based on OEE

The key OEE (Overall Equipment Effectiveness) indicator measures availability, performance, and quality of processes. By analyzing OEE, DBR77 identifies areas for optimization, enabling actions to maximize efficiency and minimize downtime.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...