The Problem We Solve

COOs face challenges in ensuring high efficiency, reliability, and operational security. Downtime, inaccurate data, and a lack of integrated tools can significantly impact production stability and incur high costs. DBR77 addresses these needs by offering integrated solutions for measuring, optimizing, and automating processes, supporting production continuity and minimizing downtime risks.

Results in Numbers

DBR77 Solutions

DBR77 supports COOs by improving efficiency, reliability, and operational stability. Key benefits include:

Real-Time Monitoring

DBR77 enables constant oversight of performance metrics like production time and throughput, allowing quick responses to deviations and ensuring operational continuity.

Operational Optimization

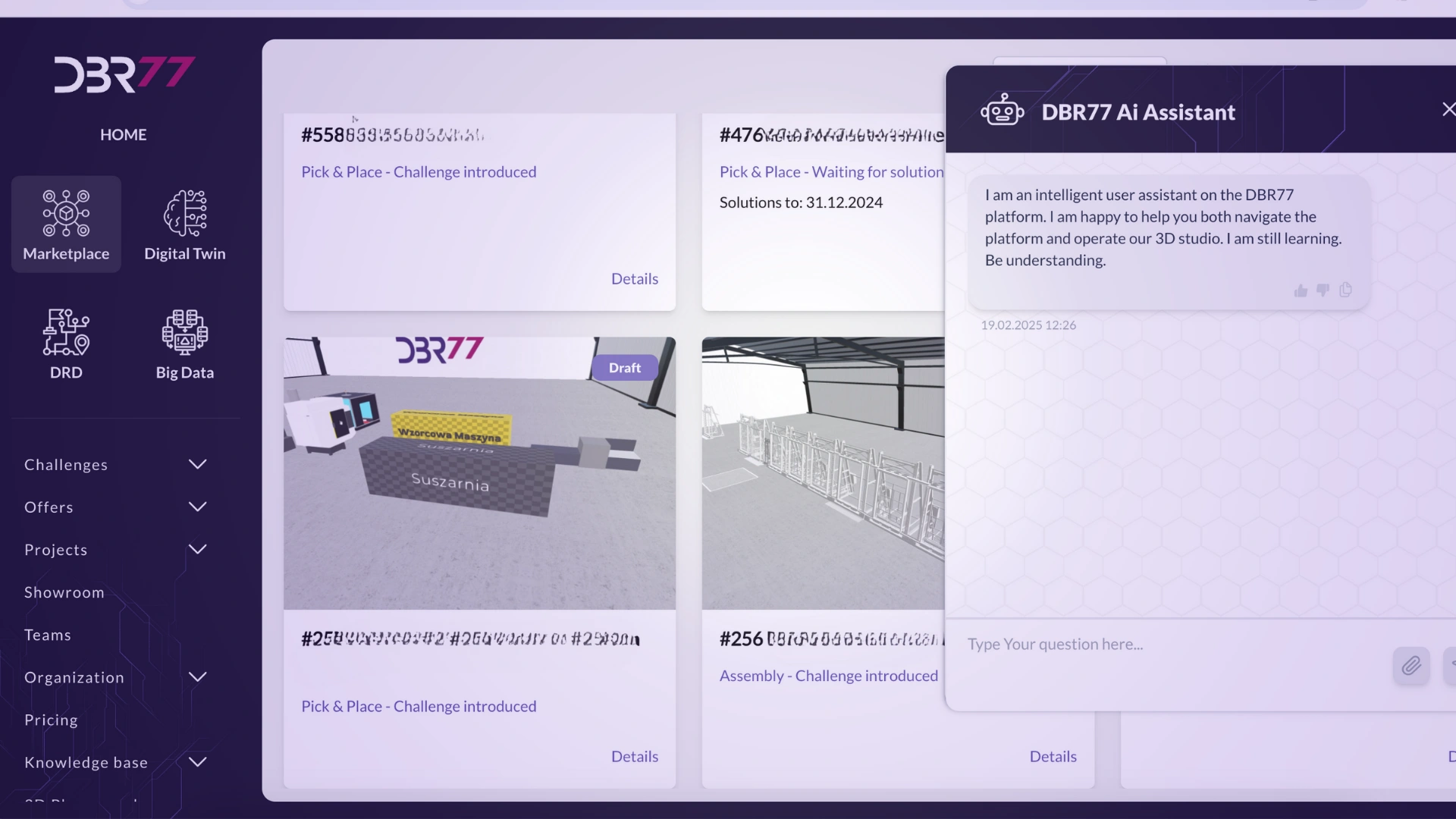

The digital twin and advanced AI algorithms analyze production processes, identifying bottlenecks and loss areas. The tool suggests precise improvements that enhance operational efficiency, optimize performance, and minimize downtime while reducing costs.

Efficient Process Automation

The DBR77 platform supports the automation of production and logistics processes, eliminating manual tasks and reducing error risks. Automation increases operational reliability, improves production stability, and optimizes resource utilization, fostering long-term business growth.

Cost Transparency

DBR77 ensures complete transparency of costs related to automation and process optimization. Financial analyses enable informed budget decisions and eliminate unnecessary expenses. This allows companies to plan investments accurately and maximize the return on investment from their projects.

Technology

DBR77 is a marketplace that provides cost transparency and access to top solutions. The AI module supports analysis and operational decisions. The integrated environment, featuring Digital Twin technology and a 3D studio, optimizes processes, enhances efficiency, and supports automation.

Why Choose DBR77?

Efficiency and Reliability

DBR77 provides tools for monitoring and optimizing processes, reducing downtime, and supporting operational continuity. Real-time monitoring enables COOs to respond quickly to changes, improving operational stability and the quality of process management.

Extensively Tested Solution

DBR77 is a trusted tool used by companies across various industries and countries. It has been tested in multiple production environments, ensuring high quality and efficiency. The platform effectively supports process optimization, minimizes errors, and enhances operational performance.

Flexible and Scalable Implementation

DBR77 enables flexible automation and easy scalability of implementations based on a company’s growing needs. Projects can be developed gradually without requiring significant financial investments. The platform supports dynamic adaptation to changing operational and budgetary requirements.

Case studies

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

News

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine...

AFT AG: Pioneering Precision in Conveyor Technology

On the DBR77 Platform we welcome Advanced Feeding Technologies AG (AFT) and its pioneering solutions in conveyor technology. AFT AG is a Swiss...

Neobotix – new Partner on the DBR77 Platform

We are thrilled to announce that all Neobotix AMR and Cobot platforms are now available on the DBR77 Platform. This partnership marks a significant...