Blog

Latest expert articles from the world of modern technology (AI, Big Data, Digital Twin) and industrial robots related to DBR77

Smart Industry Readiness Index (SIRI): The Global Gold Standard for Technical Benchmarking

In the high-stakes world of global manufacturing, intuition is no longer enough. Decisions involving millions of dollars in CAPEX require rigorous, data-backed justification. Enter the Smart Industry Readiness Index (SIRI) - a framework that has transcended its origins to...

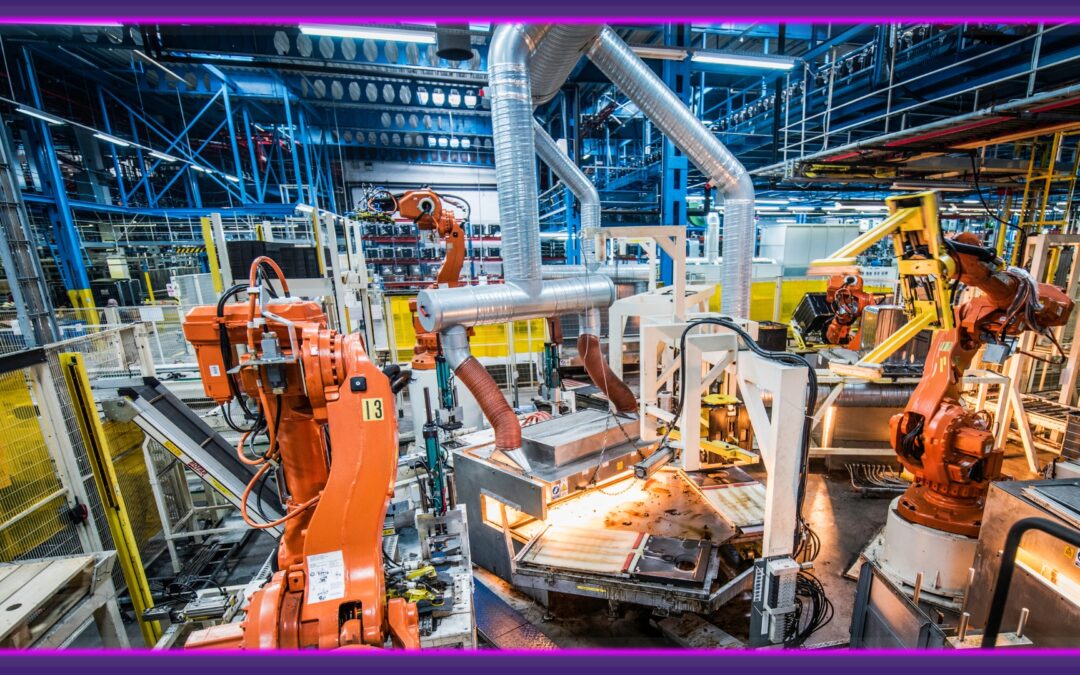

How has the direction of robotization changed over recent years?

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes. Today, the competitiveness of your plant no longer depends solely on the number of robots you have, but on the intelligence of the...

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely technocratic view toward a holistic vision that integrates sustainability and human talent. For European manufacturers, particularly Small...

RoadMap: Why Industrial Intelligence Begins with Measurement, Not a Robot Purchase?

Industrial Intelligence: Measure – Optimize – Automate. Path to success - Digital Development RoadMap We are entering 2026, a year where technology is no longer a barrier - it is a standard. However, true competitive advantage does not lie in simply owning machines; it lies in...

Robotics Trends 2026: Physical AI, Humanoids & The “Simulate-then-Procure” Shift

Discover the top robotics trends for 2026. From Physical AI and Agentic Workflows to the rise of the "Digital Nervous System." Learn how to de-risk your automation strategy. Industrial Robotics in 2026: It’s No Longer About the Machine. It’s About the Brain. By 2026, the...

From Data to Dividends: How to Measure and Maximize ROI from IoT in Manufacturing

The return on investment (ROI) from the Industrial Internet of Things (IoT) is about translating collected data into measurable savings and increased efficiency. The key is to focus on three areas: reducing maintenance costs, optimizing performance (OEE), and smart energy...

Industry 5.0 is about people. What role do cobots play in it?

Cobots in Industry 5.0 are partners for humans, not their replacements. Their key role is to augment human capabilities, take over monotonous and non-ergonomic tasks, and create a flexible, safe production environment where humans and machines work together effectively. What...

Workplace Safety in the Era of AMRs, Digital Twin, and IIoT

Introduction – Production Automation Meets Safety Innovations such as Autonomous Mobile Robots (AMRs), Digital Twin, and Industrial IoT (IIoT) are transforming how companies protect employees on the shop floor. These technologies allow businesses to increase production...

Autonomous Operations

How Generative AI, Robotics, and Digital Twins Are Creating the Self-Correcting Factory Introduction For years, the promise of Industry 4.0 has been about data. We connected machines, gathered metrics, and built dashboards. But data alone is not the endgame. The true revolution...

Determining Production Capacity and Setting Realistic Work Standards

Accurately determining production capacity and establishing realistic work standards are critical for efficient manufacturing. Without precise data, companies risk overloading resources, missing deadlines, or underutilizing equipment. This post explores how simulations and data...

Understanding the Causes of Low OEE

Many production managers know their OEE (Overall Equipment Effectiveness) is too low-but they don’t always know why, or how to react quickly. Identifying the root causes of low OEE is essential for improving operational efficiency and profitability. In this post, we’ll explain...

OEE Under the Microscope – How to Identify and Eliminate Losses

Overall Equipment Effectiveness (OEE) is a critical metric for evaluating manufacturing efficiency, combining availability, performance, and quality. While many companies track OEE, the real value lies in identifying and addressing hidden losses. Modern technologies like IoT,...

Increasing Visibility of Production Processes

Without full visibility into production processes, companies make decisions based on incomplete or outdated information-leading to wasted time, resources, and money. Real-time access to key data like OEE (Overall Equipment Effectiveness) and cycle times is now essential for...

Improving Product Quality and Reducing Defects

Defective products generate not only direct financial losses but also damage a company’s reputation and lead to customer churn. In today’s competitive market, quality is more than just a final check-it’s a continuous process supported by technology at every stage. In this post,...

Reducing Operational Costs in Manufacturing

High operational costs-energy, materials, and labor-are among the biggest barriers to improving profitability in manufacturing. Many companies struggle to maintain margins as expenses rise, but with the right data and tools, it’s possible to cut costs and use resources more...

Optimizing Production Processes for Greater Efficiency

Many manufacturing companies lose significant resources-time, money, and energy-due to inefficient processes. Issues like bottlenecks, downtime, and suboptimal workflows often remain hidden without thorough analysis. In this post, we’ll explore how data analysis and process...

Predictive Maintenance – Ending Unplanned Downtime

Unplanned equipment failures are one of the most significant hidden costs in manufacturing. Every unexpected stoppage not only brings direct financial losses but also disrupts order fulfillment and puts strain on the entire supply chain. Predictive maintenance is transforming...

How to Minimize Unplanned Machine Downtime? – A Practical Guide for Manufacturing Leaders

Unplanned machine downtime is one of the most costly and disruptive challenges in modern manufacturing. Every unexpected breakdown leads not only to direct financial losses, but also to operational and organizational disruptions. In this episode, we’ll explore how advanced...

How to Effectively Monitor Production in Real Time – A CEO’s Guide to Data-Driven Manufacturing

In today’s fast-paced manufacturing world, success depends on having immediate access to accurate, up-to-date information about your production processes. When you lack full visibility into what’s happening on the shop floor, delays, unplanned downtime, and declining...

IoT in manufacturing – sensors in the data collection process.

This is another article in our series on IoT in manufacturing and its practical applications in industry. In previous texts, we discussed machine monitoring and production data analysis. Today we will focus on one of the key performance indicators - cycle time. How exactly do...

Cycle time – the key to efficient production

So how can cycle time be measured and optimised automatically? What is cycle time and why is it important in manufacturing? Cycle time is the time required to complete the entire production process for a single product unit at a given workstation, including both work operations...

Industrial IoT – automatic collection of production data

Why is production data collection important? Modern production facilities operate in highly volatile conditions, where short production runs and product customisation are becoming the norm. Uncertainty in supply and global disruptions in logistics chains further complicate...

Impact of the COVID-19 pandemic and the conflict in Ukraine on the robot market

The COVID-19 pandemic and the conflict in Ukraine had a decisive impact on the robot market between 2021-2023. They revealed the complexity and challenges faced by the global robotics industry. Both events contributed to significant disruptions in global supply chains, directly...