The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes. Today, the competitiveness of your plant no longer depends solely on the number of robots you have, but on the intelligence of the entire ecosystem that connects machines, data, and people.

A decade ago, robotization meant putting a machine in a safety cage that performed a single task for years. Today, as indicated by the latest reports from the International Federation of Robotics (IFR) and DBR77 market analyses (The Automation Gap: Why the U.S. is Losing the Robotics Race (and How to Win It Back)), we are entering the era of “AI-native production.” Machines not only operate, but also see, predict failures, and generate the code necessary for their operation themselves.

What is “Intelligent Robotics” and why are you losing out by not knowing about it?

The traditional definition of a robot as a “dumb machine” is becoming obsolete. The IFR report “AI in Robotics” clearly indicates that artificial intelligence is transforming from a supporting technology into a key enabler of implementation.

How does this work in practice? Modern robotization is a fusion of three elements that transforms factories into autonomous ecosystems:

- Physical robotics – which is becoming cheaper and more accessible.

- Artificial Intelligence (AI) – which allows robots to “see” (vision systems) and “think” (machine learning).

- Data and Digital Twins – which allow you to test processes virtually before you spend a single dollar on equipment.

Why is this a critical moment for C-level executives?

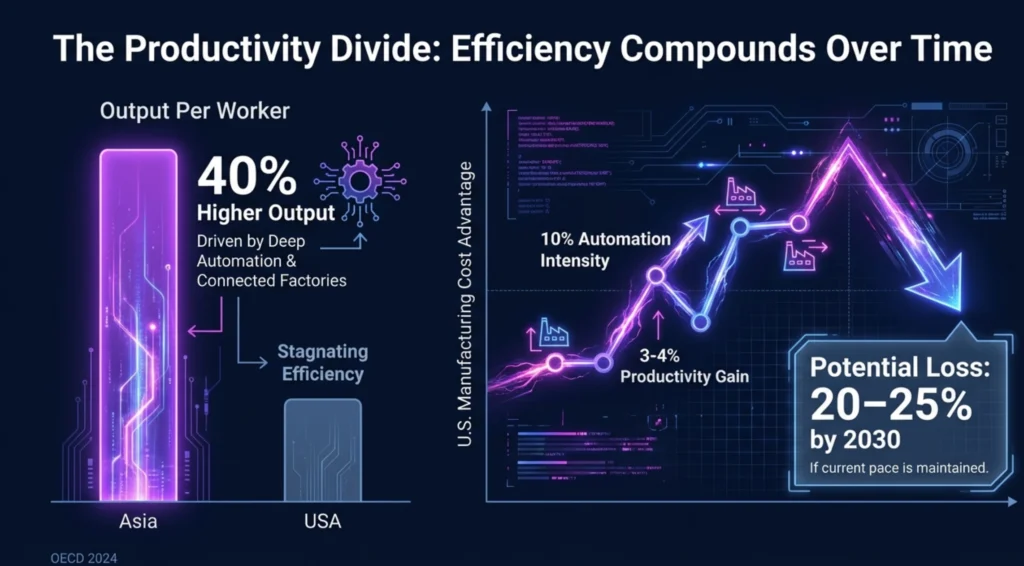

The data is compelling. Plants that implement deep automation and connected factories achieve up to 40% higher productivity per worker than their less automated competitors. What’s more, every 10% increase in automation intensity translates into a 3–4% increase in productivity. If your plant relies solely on cheap labor rather than technology, you risk losing a cost advantage of 20-25% by 2030.

Deep automation and connected factories in Asia result in 40% higher output per worker, signaling a critical need for US industrial modernization to avoid a 25% cost disadvantage by 2030.

Traditional robotization or AI-supported robotization – which to choose?

You are faced with a choice: a classic, rigid robotic workstation or a flexible, data-driven solution? The key to making this decision is understanding the so-called “Digitalization Deficit.”

Table Comparison of approaches: Old School vs. New Wave (according to IFR and DBR77)

| Feature | Traditional (Mechanical) Robotization | Modern (Cognitive/AI) Robotization |

| Main task | Repeatability (the same action millions of times). | Adaptation (dealing with variable products). |

| Programming | Requires expensive experts and complex code. | Generative AI – robots create code based on natural language commands. |

| Maintenance | Reactive (repair after failure). | Predictive Maintenance – AI predicts failure before it occurs. |

| Implementation | Trial and error on a physical machine. | Digital Twin – simulation and optimization before purchase. |

What are the hidden costs and risks?

Many CEOs fear that robotization is a “bottomless pit.” This is true – but only if you automate chaos.

Problem: Only 28% of American SMEs use IoT systems to manage production. Without data, you can’t optimize.

Risk: Implementing a robot in an unmeasured process is a recipe for failure.

Solution: DBR77 methodology “Measure → Optimize → Automate”. Data first, machines second.

Trends that are changing the rules of the game

- Generative AI in programming: The barrier to entry is falling dramatically. New tools allow robots to be programmed using voice or text, reducing dependence on expensive integrators.

- Collaborative robots (Cobots): Thanks to AI, they are becoming safer and can work side by side with humans without cages.

- Cybersecurity: Because robots are now connected to the cloud, they are becoming targets for attacks. Modern implementations must take this aspect into account.

How to implement robotization and not lose out?

Choosing the best solution in 2026 is not about buying the fastest robot, but about building the smartest process.

3 steps to a safe decision

- Start with a process simulation (Digital Twin)

Don’t buy a pig in a poke. Reports show that using digital twins for simulation reduces downtime by up to 50%. Test your workstation in the virtual world before investing in physical equipment.

- Focus on AI and prediction

Look for solutions that offer predictive maintenance. These systems analyze sensor data to detect errors before they stop the line. It’s a saving that pays for itself in no time.

- Choose an ecosystem, not just a supplier

Avoid fragmentation. Use platforms (like Marketplace) that bring together certified integrators, technology providers, and project management tools in one place. This reduces implementation time from months to weeks.

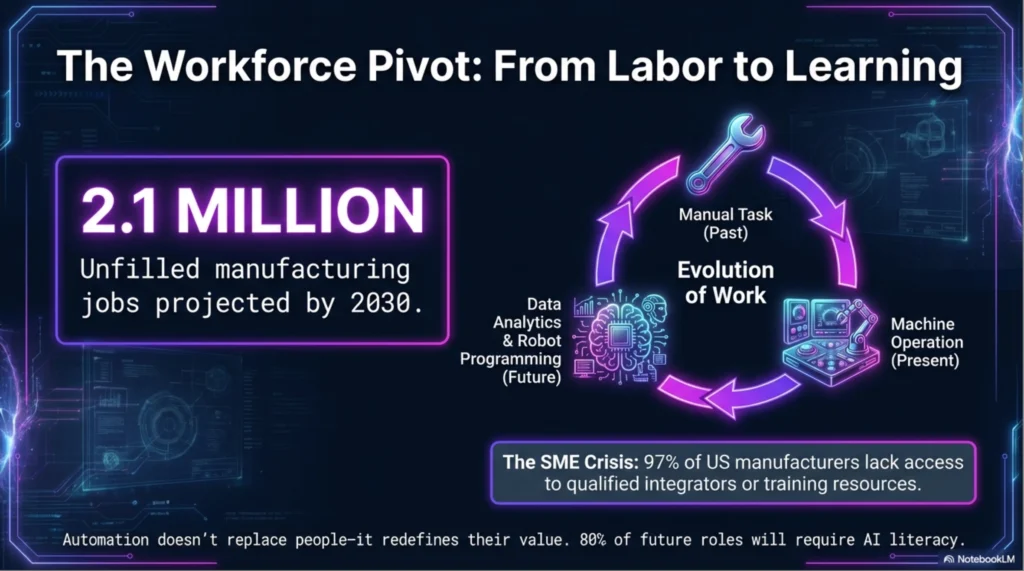

By 2030, the manufacturing sector faces a 2.1 million worker shortage, shifting the focus from manual labor to data analytics and robot programming.

Where to look for savings?

Not in cheap equipment, but in integration. Systems combining IIoT (Industrial Internet of Things), AI, and simulations can increase productivity by 15-25%. This is where the real return on investment (ROI) lies.

FAQ – Questions you are afraid to ask

No, statistics say otherwise. Countries with high robotization density have seen a 15-20% increase in employment in technical sectors. Robots take over boring and dangerous tasks, while people are promoted to supervisory and analytical roles. This is an evolution of work, not its end.

Yes, provided you don’t act “blindly.” The cost of robots is falling, but the cost of implementation errors is high. That’s why it’s crucial to use tools such as the DBR77 Platform, which allows small and medium-sized companies to access technologies previously reserved for giants.

It’s already happening. Experts predict that between 2030 and 2035, general AI systems for robots will be developed that will allow them to adapt to any task. However, generative algorithms (LLM) are already helping to create code for robots, which makes them much easier to use for people without a PhD in computer science.

The main challenge is the so-called “black box” (lack of transparency as to how AI made a decision) and cybersecurity. That is why it is so important to choose proven partners and solutions that comply with new regulations.

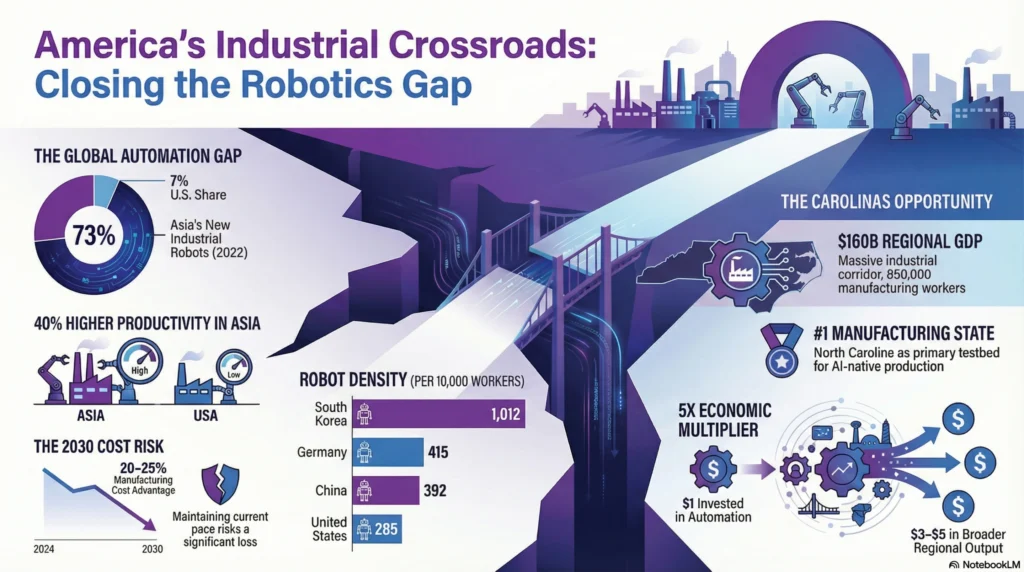

The United States faces a significant robotics gap compared to Asia, but regions like the Carolinas are positioned as key hubs for AI-native production and industrial growth.

Don’t let your plant remain in the analog era

The world is accelerating. Asia currently installs 70% of all new robots worldwide, treating automation as critical infrastructure. Faced with a productivity gap, inaction is the most expensive decision possible.

Want to explore the potential of robotics in your plant without risk?

Use the DBR77 methodology: Measure, Optimize, then Automate. Schedule a meeting with our expert.

Start a free analysis on the DBR77 Robot Platform and enter the era of Industry 4.0.