The Problem We Solve

Today, logistics companies face challenges such as rising operational costs, the need to optimize processes, and dynamic market changes. Additional difficulties stem from a lack of human resources, high employee turnover, and the unpredictability of tasks. DBR77 supports logistics organizations by enabling automation and digitization to meet the demands of modern supply chains.

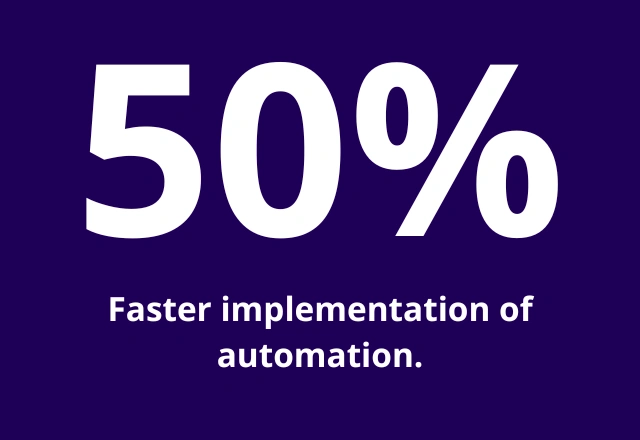

Results in Numbers

DBR77 Solutions

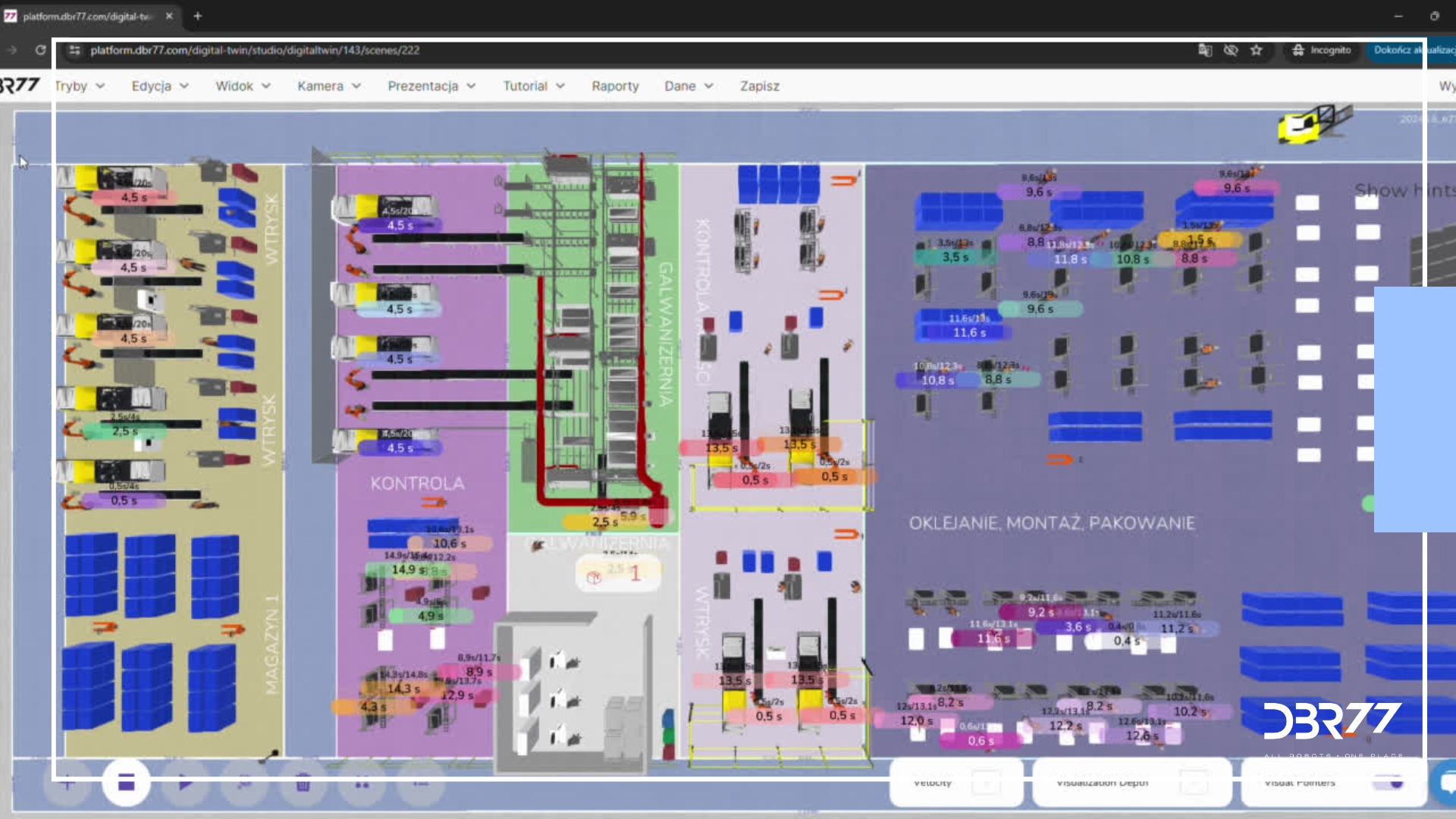

Automatic Measurement of Logistics Processes

Precise measurements of operation times and efficiency analyses of logistics activities allow for identifying areas that require improvement. This enables the optimization of material flows, elimination of bottlenecks, and improvement of overall process efficiency.

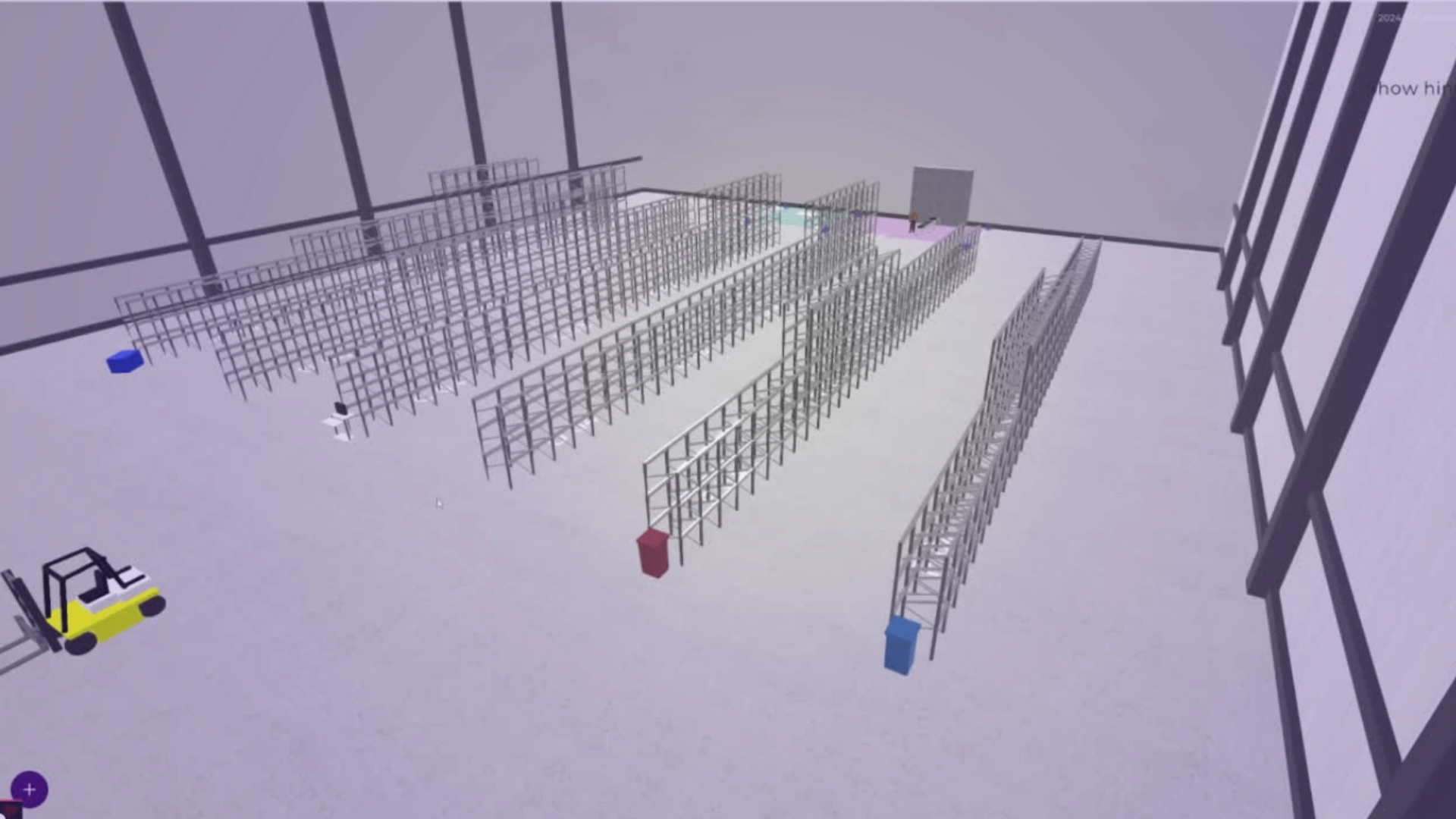

Optimization of Warehouse Layout and Transport Routes

The digital twin enables realistic simulations of various warehouse layouts and the analysis of transport routes for goods movement. Virtually testing alternative configurations helps reduce operational time, optimize space utilization, and lower logistics costs.

Automation of Intralogistics Tasks

The implementation of advanced robots for goods transport, order picking, and inventory management reduces dependence on manual labor. Automation positively impacts operational costs by minimizing labor expenses while improving work quality through error elimination and increased precision. Additionally, it allows for better scalability of logistics processes.

Advanced DBR77 Technologies for Logistics

The DBR77 Digital Twin is an ideal solution for visualizing and simulating warehouse areas and logistics operations within warehouses and logistics centers. It enables companies to model and analyze processes for better planning and optimization. Furthermore, VR technology supports precise space design and detailed analysis of logistics flows, enhancing resource and operation management efficiency.

Why Choose DBR77?

Tailored Expertise for Logistics Operations

DBR77 is a platform developed by experts who understand the unique needs of logistics companies. It offers precise tools for automating, monitoring, and optimizing processes, helping to effectively manage logistics operations and boost their efficiency.

Flexibility for Any Type of Operation

IoT and digital twin solutions are designed for a wide range of logistics processes. These systems can be easily adapted to the specifics of any operation, from warehouse management to complex transport networks, ensuring cost and time optimization.

Decision Support with AI

nalysisAdvanced AI-based analytical tools process data in real time. This enables companies to make more informed operational decisions, identify bottlenecks, and predict trends, leading to higher efficiency and cost savings.

Case study

DBR77 enables logistics companies to achieve measurable benefits through the digitization and automation of processes:

1. Optimal Material Placement in Warehouses

The DBR77 Digital Twin enables analysis and optimization of resource placement, streamlining material flow and reducing operation times.

2. Standardization of Work and Resource Planning

DBR77 allows for the establishment of work standards for warehouse tasks and determining workforce requirements, supporting effective human resource management and improving operational efficiency.

News

Robotics Trends 2026: Physical AI, Humanoids & The “Simulate-then-Procure” Shift

Discover the top robotics trends for 2026. From Physical AI and Agentic Workflows to the rise of the "Digital Nervous System." Learn how to de-risk...

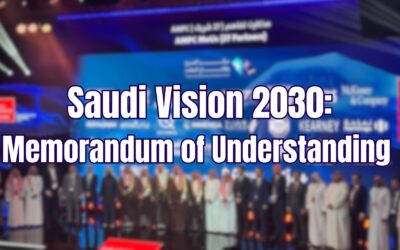

DBR77 Signs Strategic MoU with Saudi Ministry of Industry to Support “Future Factory” Program and Vision 2030

Riyadh / Berlin / Warsaw / Charlotte - December 2025. It is a defining moment for our global expansion. DBR77 has officially signed a strategic...

IEX 2025 Recap: DBR77’s Historic Charlotte Launch Ignites “From Lean to AI” Conversation

Thursday, October 16th, 2025, marked a historic milestone for DBR77. Inside a packed PORTAL Atrium at UNC Charlotte, the inaugural IEX: Innovation...