Problem We Solve

IRIS is the world’s first Plant Operation System (POS) – an operating system for factories that manages people, machines, and processes in real time. It connects the entire automation pyramid: from data from IoT sensors, through MES, WMS, QMS, HRM, CMMS, and MRP modules, to APS, Digital Twin, and artificial intelligence, which ties everything together into a single organism.

This is not just another MES or ERP. It is the brain of the factory that learns, analyzes, and automates.

Why IRIS? – 6 pillars of uniqueness

The complete automation pyramid

IRIS covers the entire ecosystem: from IoT sensor data, through MES, APS, and AI, to strategic planning. All layers of automation operate in a single, coherent system.

AI without limits

IRIS utilizes the entire spectrum of artificial intelligence – from machine learning, through simulations and synthetic data, to language models (LLM). This combination guarantees real transformation.

Task-driven production

Real-time data is converted into precise tasks for people, robots, and machines. Operators receive automatic tasks on tablets and mobile applications—the foundation of autonomous production. We are waiting for humanoid robots.

End-to-end process integration

One system for all operational areas: production, logistics, quality, maintenance, and planning. IRIS eliminates information silos and ensures complete transparency.

Software–hardware–communication combination

IRIS is more than just software. It provides sensors, operator panels, and communication systems to ensure that the right data always reaches the right person at the right time.

Software–hardware–communication combination

IRIS is more than just software. It provides sensors, operator panels, and communication systems to ensure that the right data always reaches the right person at the right time.

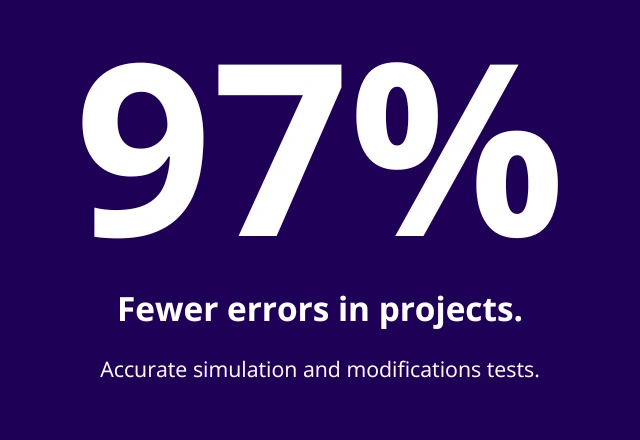

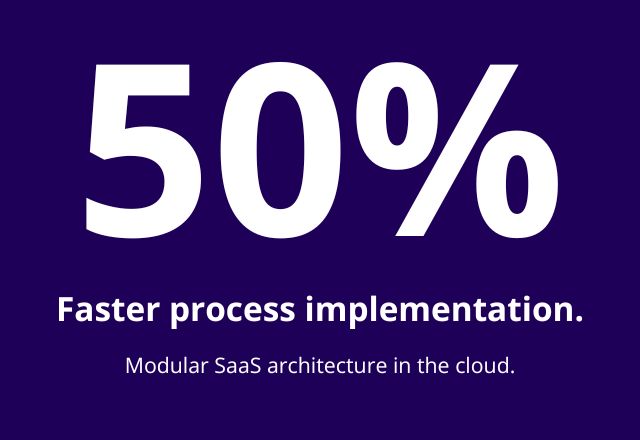

Benefits in numbers

How does IRIS work?

IRIS77 is the world’s first operating system for factories. It connects people, machines, and processes into a single intelligent ecosystem that learns and grows with the organization.

Its operation is based on four steps:

- Data collection – IoT sensors, machines, robots, and IT/OT systems transmit data in real time.

- Analysis and context – information is interpreted by MES, WMS, QMS, CMMS, HRM, and MRP/APS modules.

- Decision and recommendation – AI (Machine Learning, Digital Twin, LLM) transforms data into specific tasks and scenarios.

- Execution and optimization – operators, technicians, and robots receive personalized tasks in mobile applications and on production screens.

IRIS77 turns data into action. This makes the factory a learning and autonomous system.

IRIS77 features and capabilities

IoT & Data Hub – Internet of Things & Data Hub

Collects data from machines, sensors, and production systems, ensuring IT/OT consistency.

- Integration with PLCs, robots, sensors, and ERP.

- Data synchronization with other systems in the plant.

- Dedicated hardware for real-time data collection and communication.

- AI detects anomalies and patterns in data streams.

IRIS77 creates a single central data hub – ready for analysis and automation.

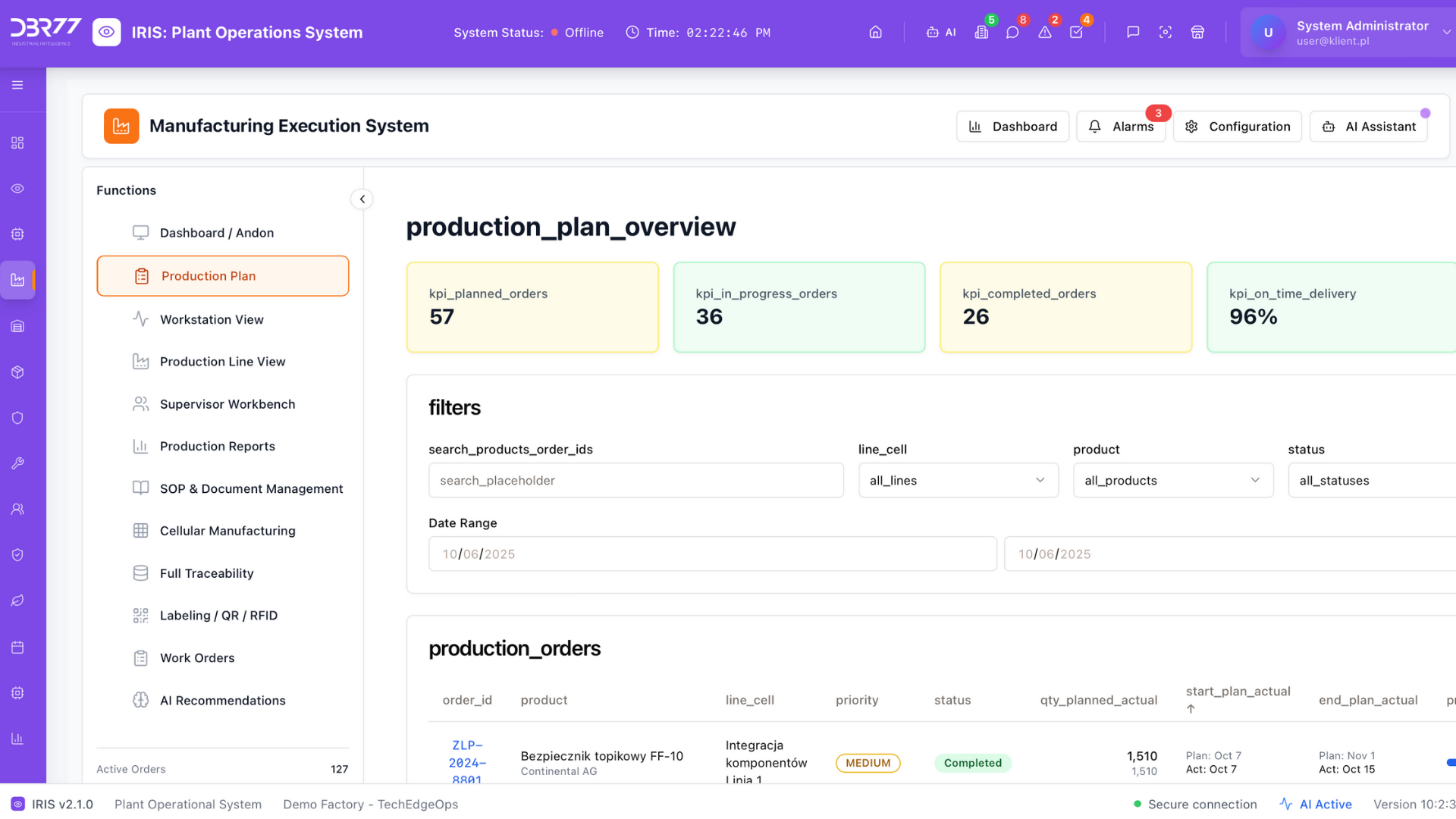

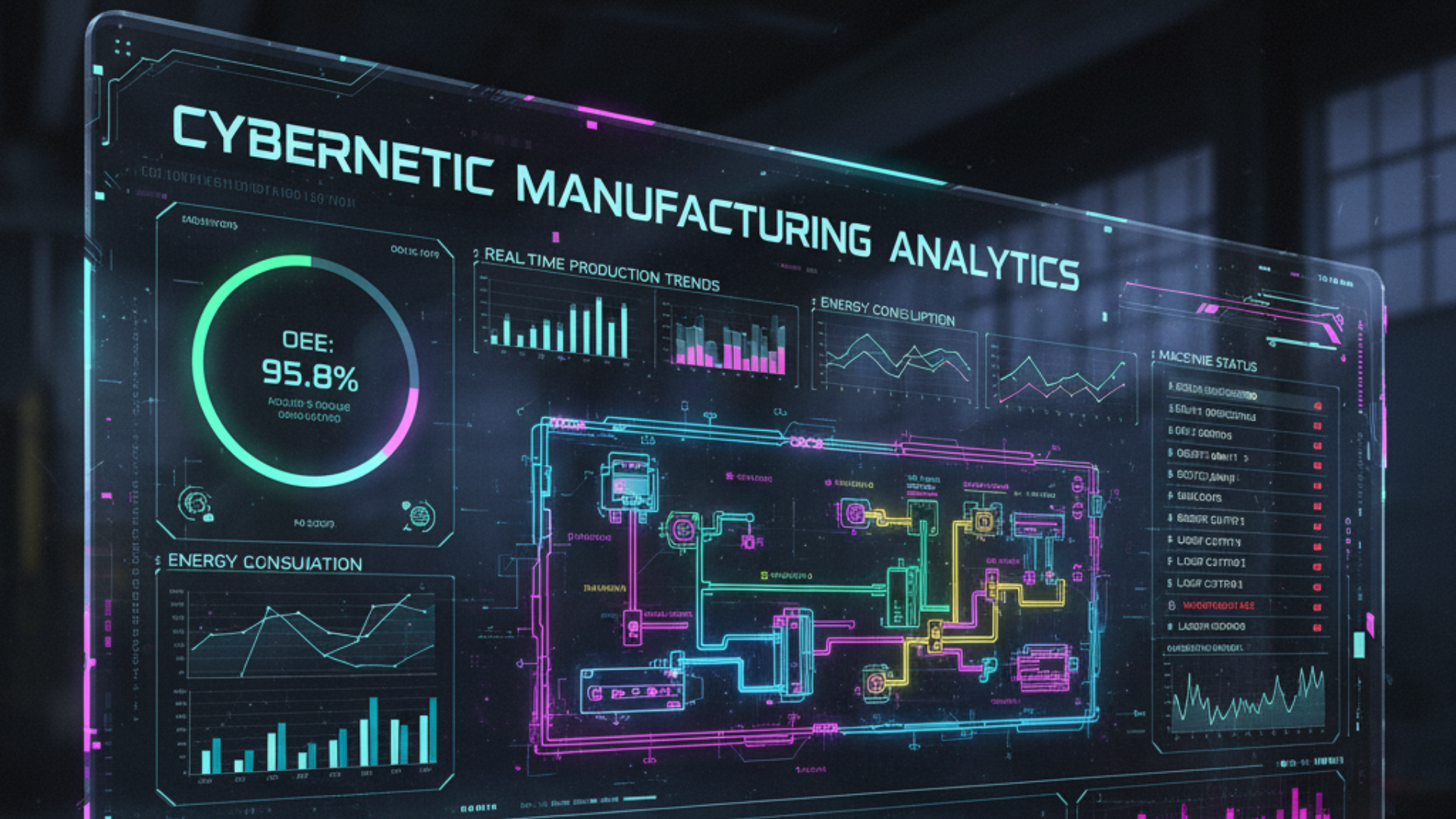

MES – Manufacturing Execution System

Monitors and optimizes the production process in real time.

- Monitoring cycles, downtime, and OEE.

- Reporting on line quality and efficiency.

- Collaboration with operators via mobile apps and tablets.

- AI predicts downtime and optimizes machine schedules.

IRIS77 supports managers and operators – decisions are made based on data.

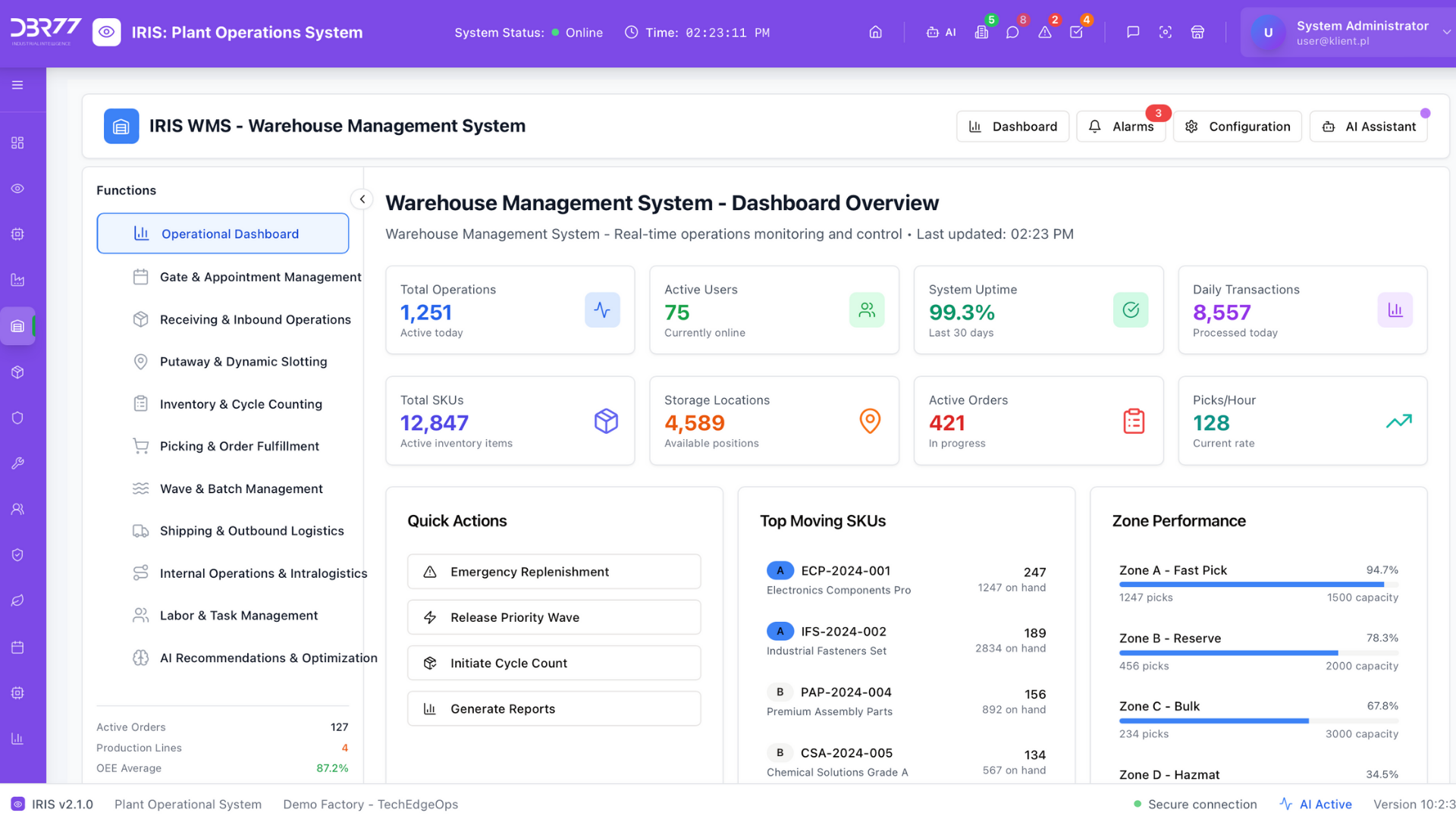

WMS – Warehouse Management System

Manages the warehouse and material flow directly from the POS level.

- Automatic receipt, release, and tracking of materials in real time.

- Integration with production and intralogistics (AGV/AMR, robots, manual transport).

- Determination of routes, locations, and rotation of materials using AI simulation.

- Management of delivery times and windows.

IRIS77 treats the warehouse as part of production – with no delays between the plan and the physical movement of materials.

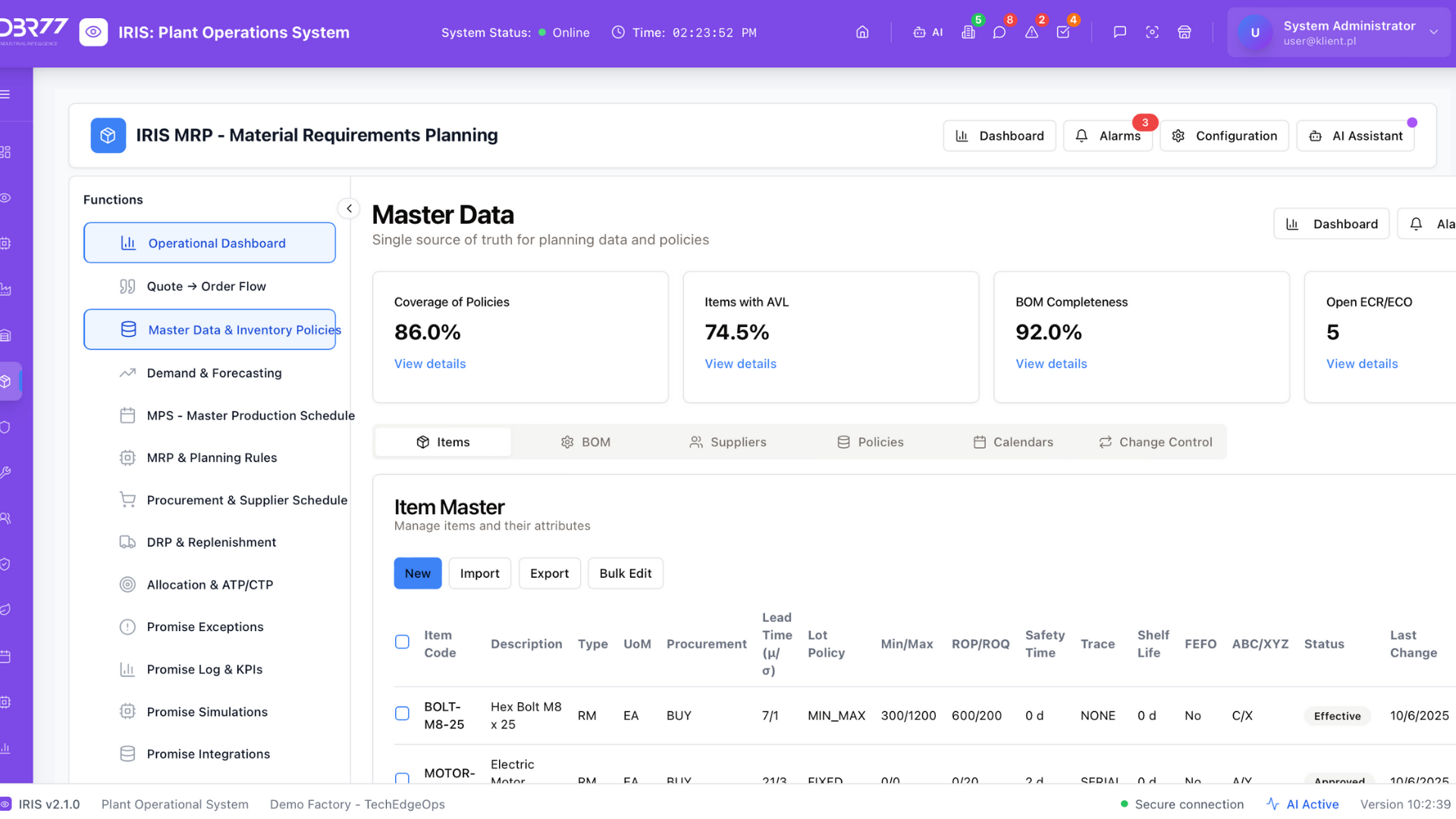

MRP – Material Requirements Planning

Planning material requirements in advance.

- Automatic balancing of materials and components.

- Integration with production and purchasing schedules.

- Dynamic response to changes in orders and deliveries.

- AI forecasts demand based on historical data and trends.

IRIS77 ensures that materials are available at the right time and place.

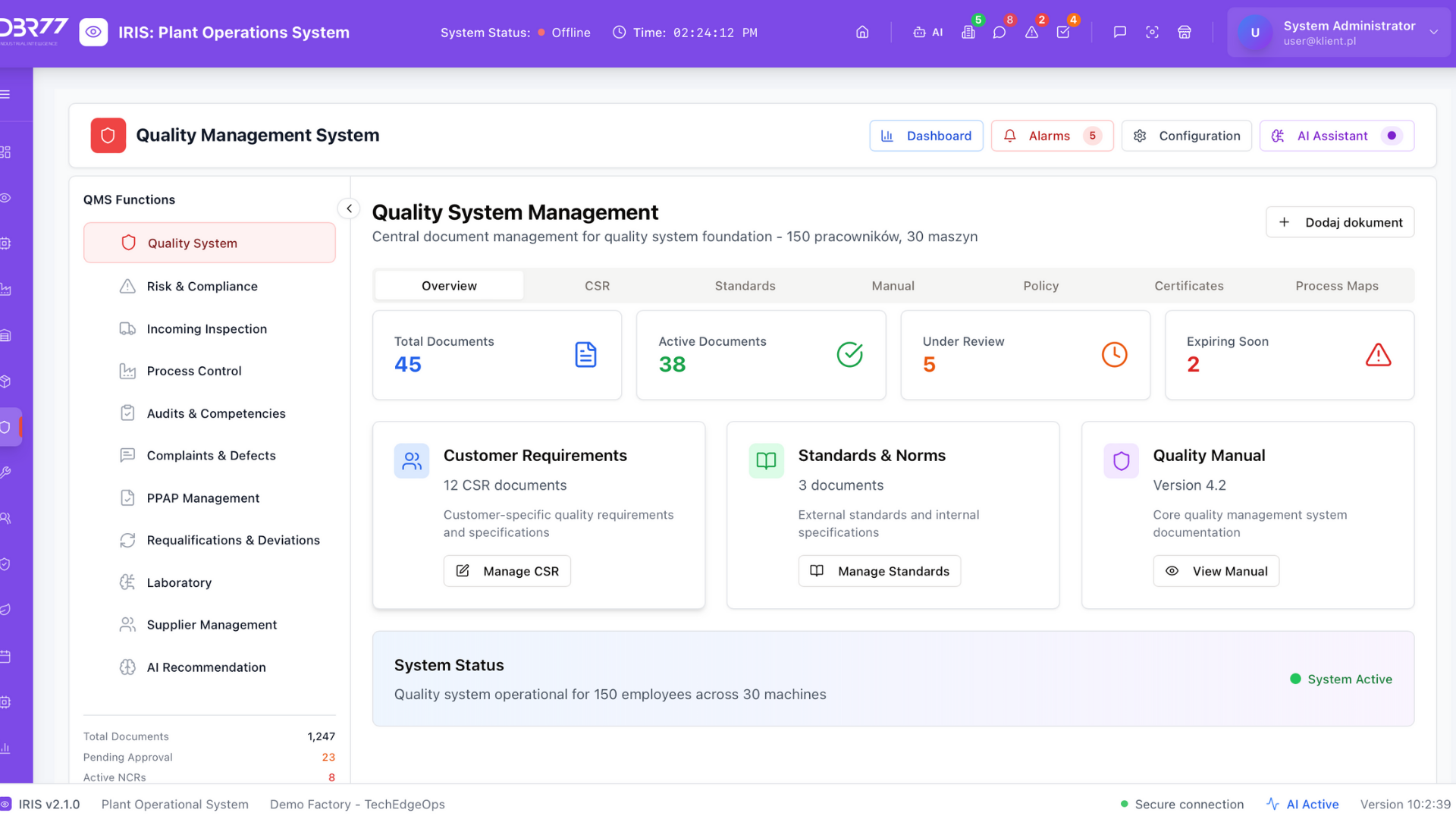

QMS – Quality Management System

Quality control of processes and products at every stage.

- Automatic records of inspections and quality tests.

- Root cause analysis of errors and non-conformities.

- Integration with reporting and certification systems.

- AI supports defect detection, analyzes images, and suggests corrective actions.

IRIS77 improves quality, reduces losses, and minimizes the risk of complaints.

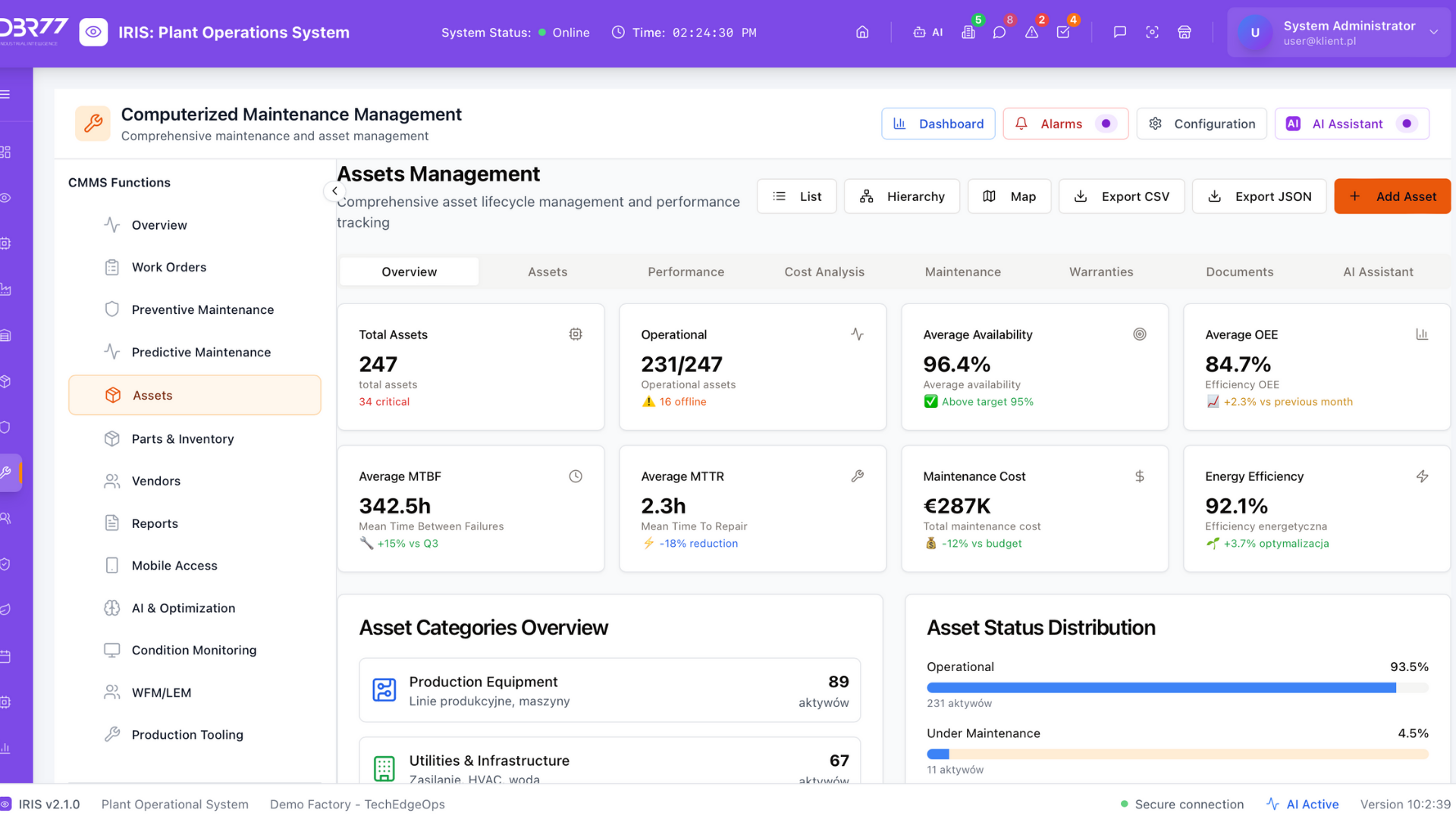

CMMS – Computerized Maintenance Management System

Maintenance management and predictive maintenance.

- Planning and monitoring service tasks.

- Failure prediction through IoT data analysis.

- AI-supported machine performance analysis – early detection of deviations.

- Recording of fault history and corrective actions.

IRIS77 reduces downtime and extends machine life.

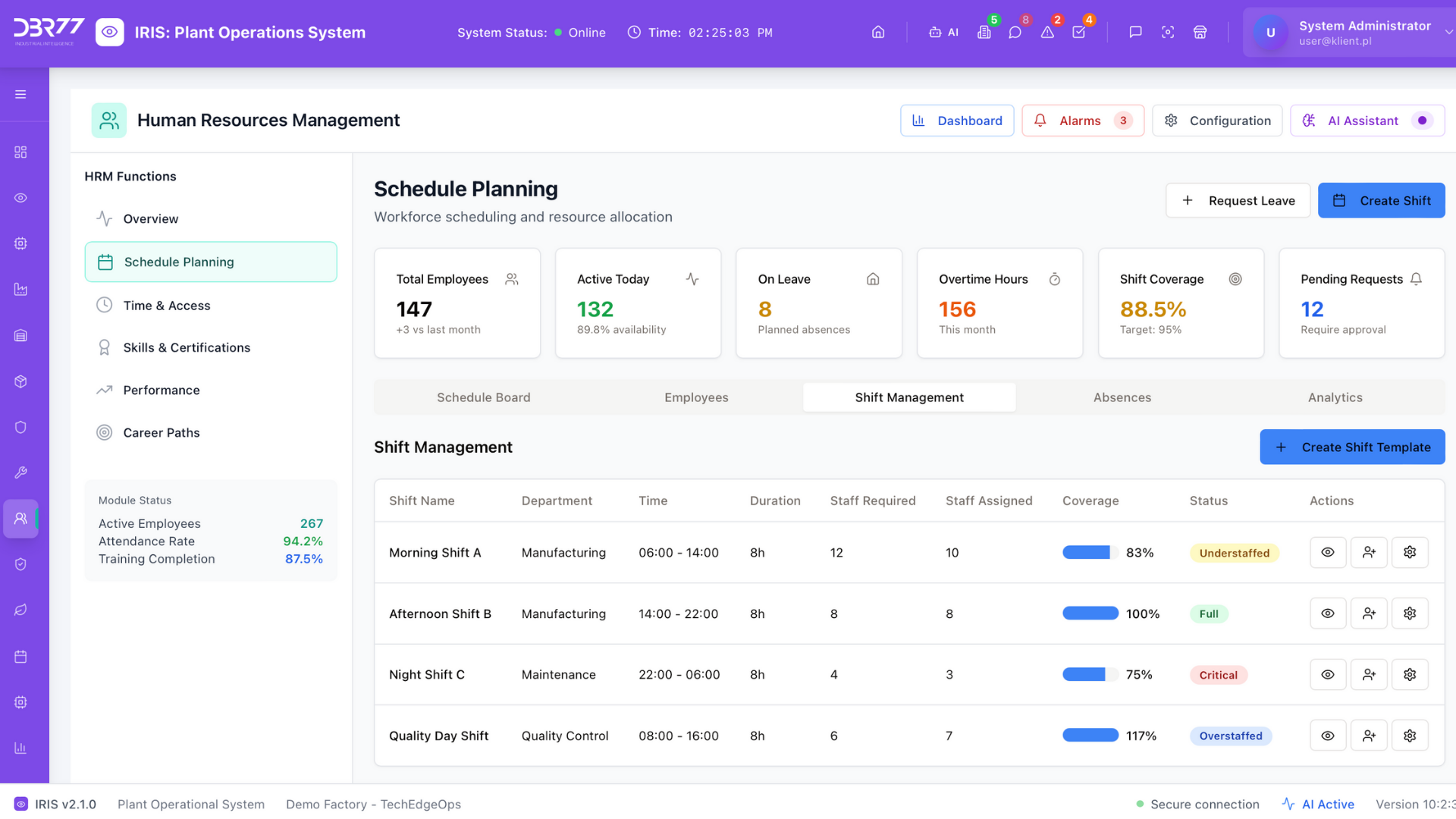

HRM – Human Resource Management

Optimization of team work and competencies.

- Recording of working time and attendance.

- Automatic assignment of tasks and shifts.

- Competence analysis and matching operators to positions.

- AI supports shift planning and forecasts staffing needs.

IRIS77 connects people and technology – increasing employee efficiency and satisfaction.

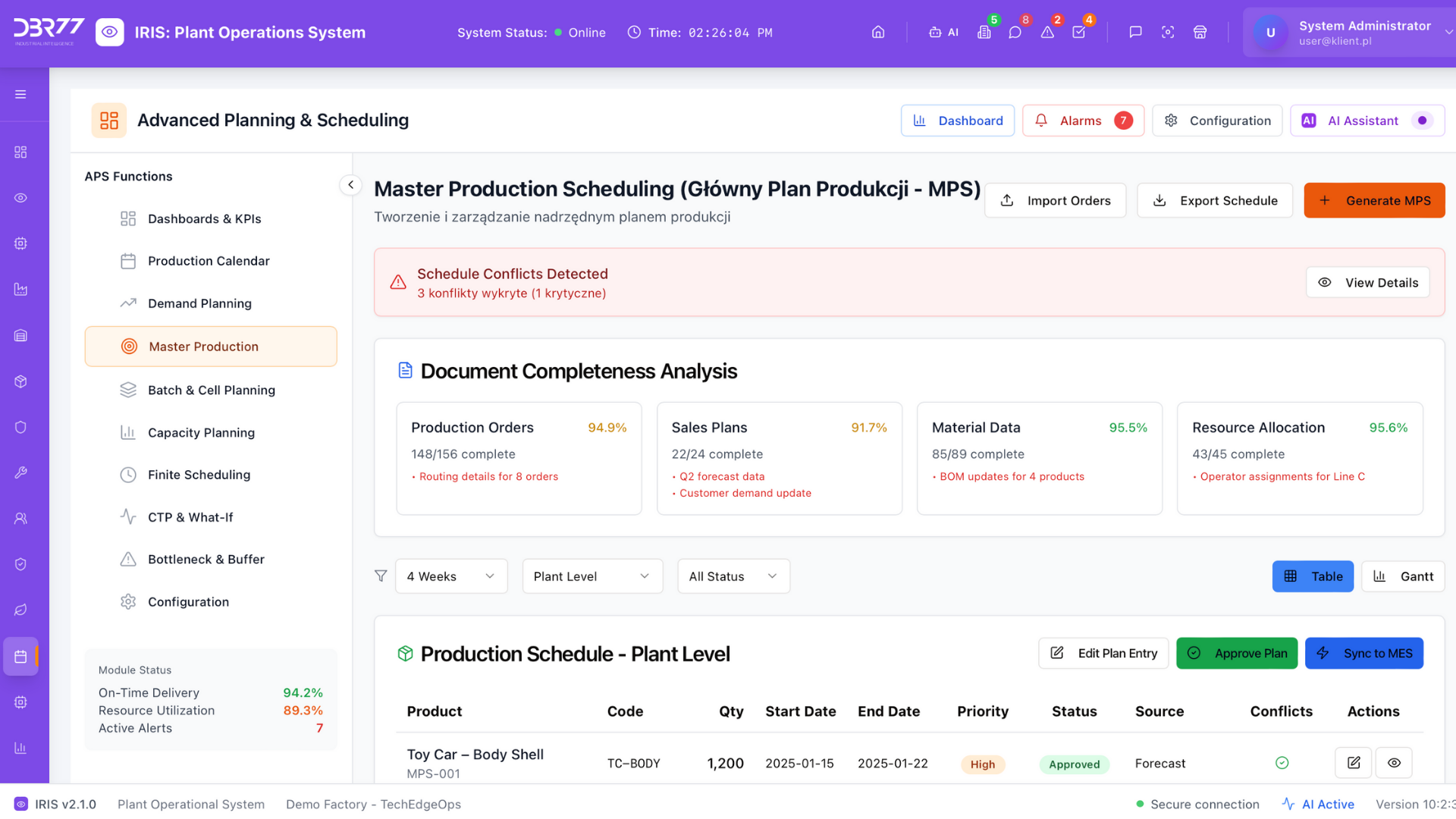

APS – Advanced Planning & Scheduling

Zaawansowane planowanie i harmonogramowanie produkcji.

- Tworzenie harmonogramów zgodnych z terminami dostaw.

- Symulacje scenariuszy „co-jeśli” w Digital Twin.

- Optymalizacja obciążenia linii i maszyn.

- AI rekomenduje najlepsze scenariusze produkcyjne.

IRIS77 zwiększa przewidywalność i terminowość procesów.

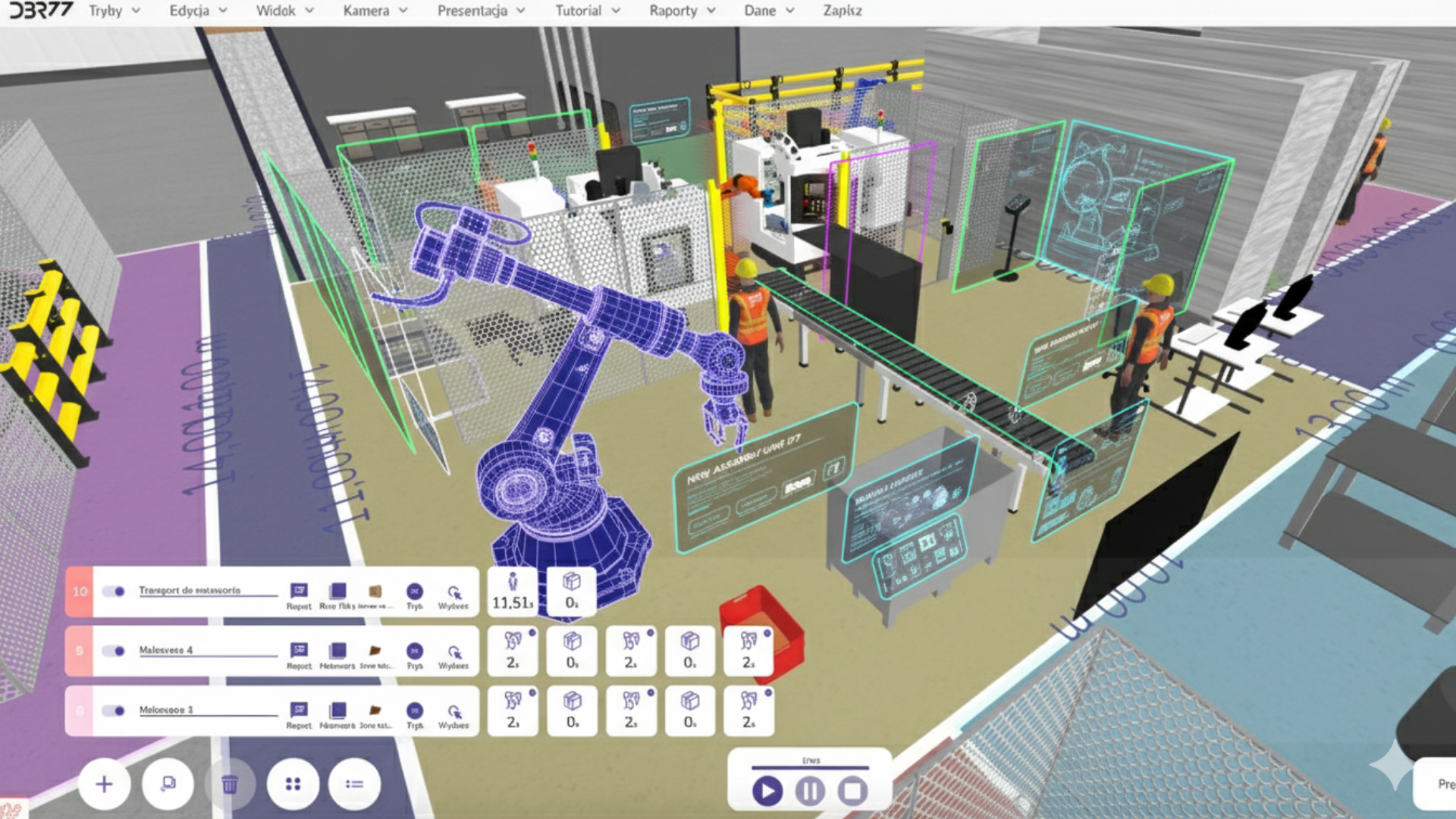

DT – Digital Twin

A digital twin of a production plant enables testing and optimization of processes in a virtual environment.

- Modeling of production lines and material flows.

- Simulations of “what-if” scenarios before implementation in reality.

- Analysis of the impact of changes on OEE, costs, and timeliness.

- AI accelerates model calibration and recommends optimal settings.

IRIS77 allows you to make decisions based on simulation rather than intuition.

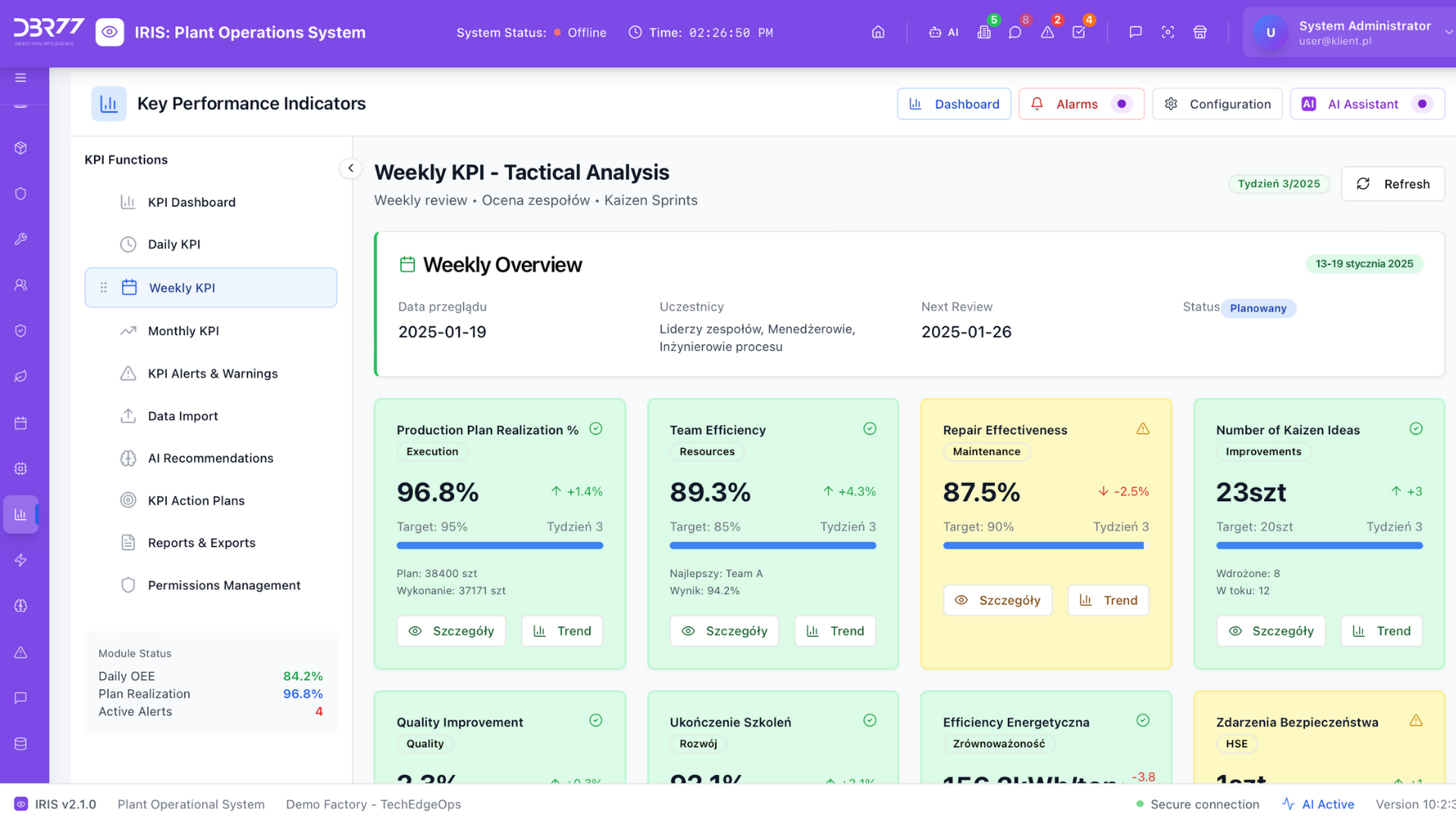

KPI – Key Performance Indicators

A system for reporting and monitoring key performance indicators in real time.

- Tracking OEE, quality, productivity, and timeliness.

- Visualization of results on management dashboards.

- Alarms and notifications of deviations from the norm.

- AI analyzes trends and identifies areas for improvement.

IRIS77 ensures transparency and full control over production results.

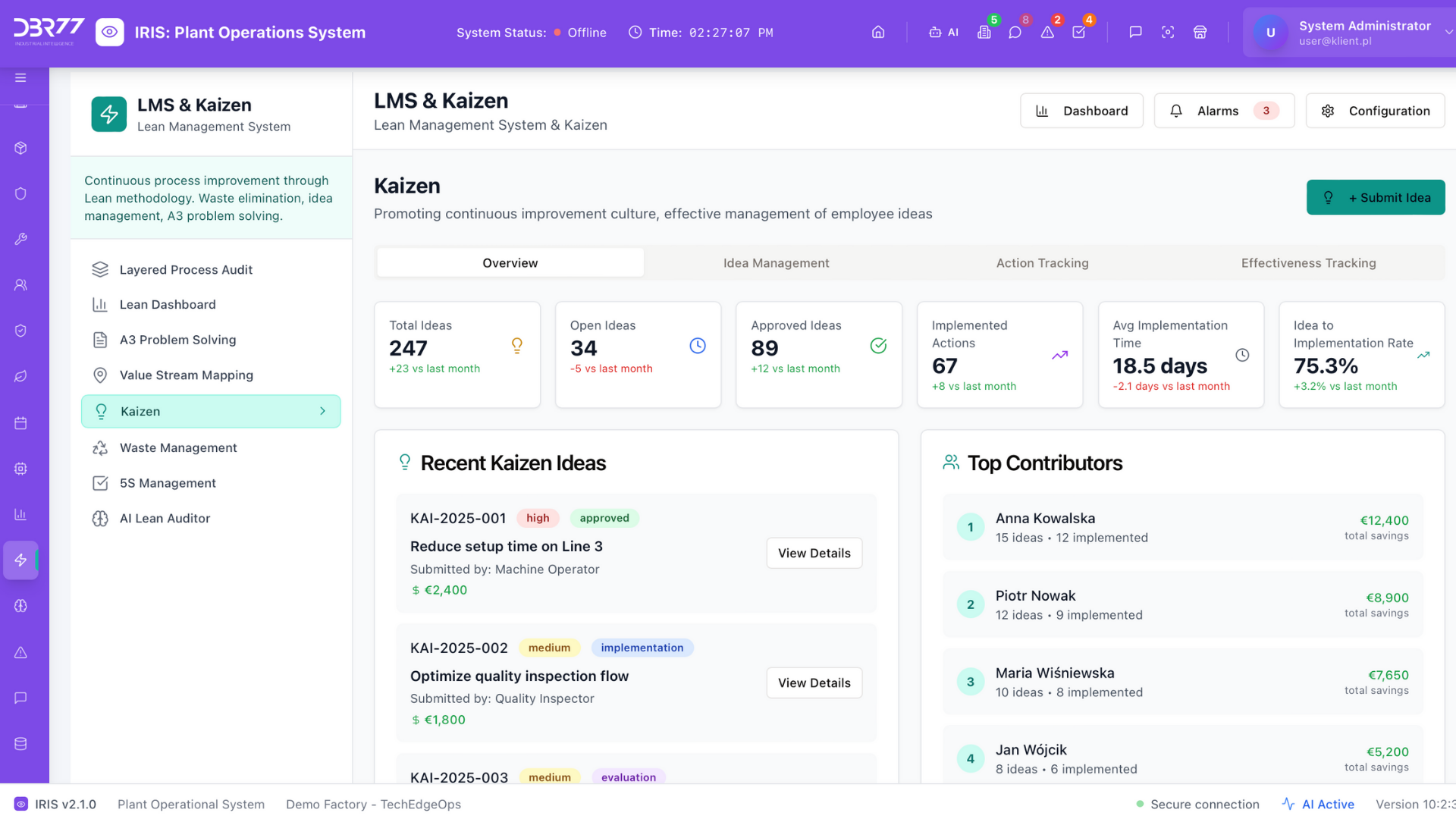

LMS – Lean Management System

A system supporting process improvement based on Lean methodology.

- Layered Process Audit (LPA): systematic process audits, monitored in real time.

- A3 Problem Solving: a structured approach to problem solving.

- Value Stream Mapping: mapping the value stream to eliminate waste.

- Kaizen and Waste Management: identifying and eliminating waste with the help of AI Lean Auditor.

IRIS77 integrates Lean methods into a digital environment where AI supports analysis and proposes improvement measures.

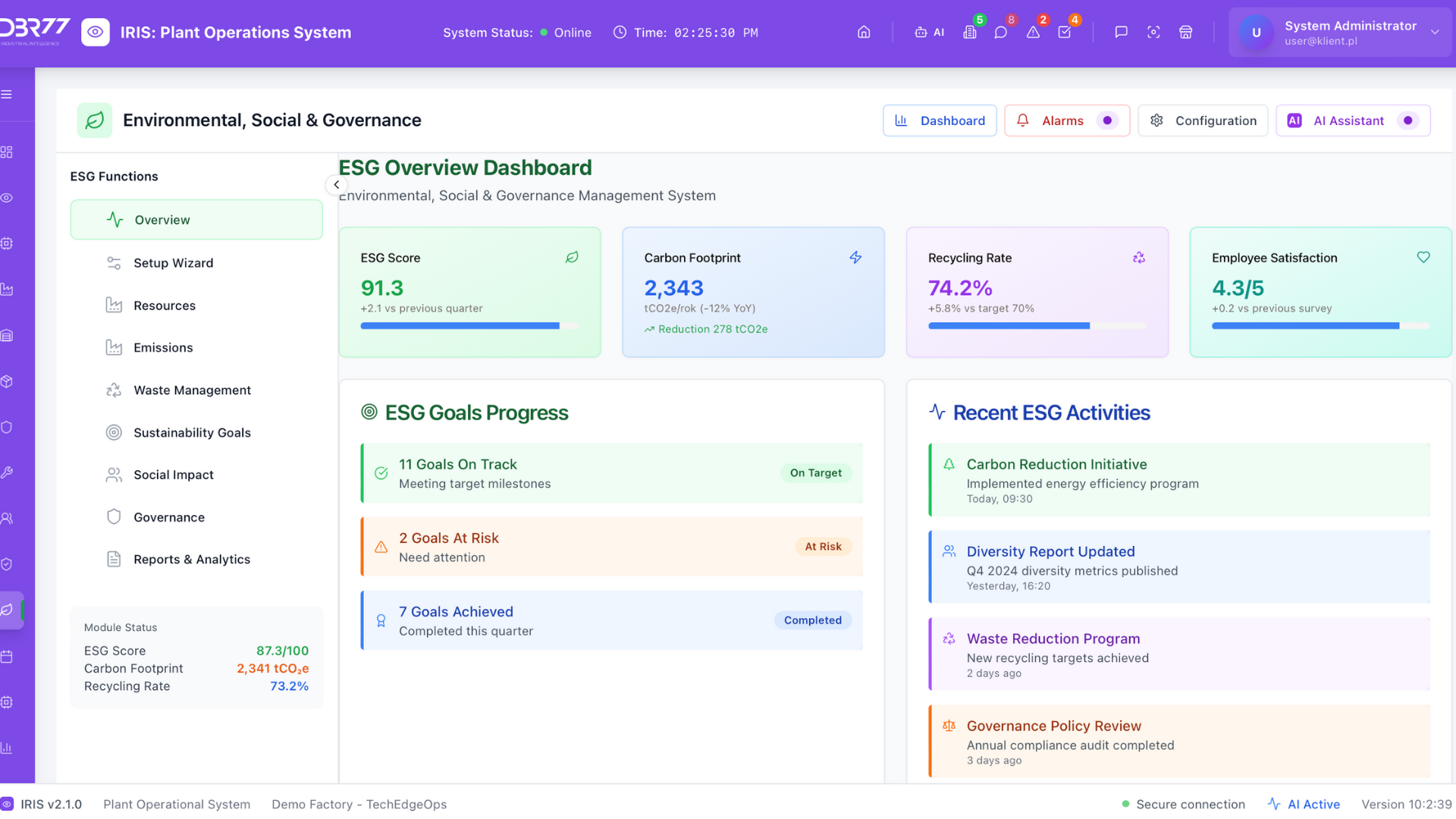

ESG – Environmental, Social & Governance

A tool for monitoring and reporting on sustainable development.

- Tracking energy and water consumption and CO₂ emissions.

- Monitoring occupational safety and social indicators.

- Automatic reports compliant with ESG standards.

- AI analyzes environmental data and suggests actions to reduce your carbon footprint.

IRIS77 supports companies in meeting ESG requirements and building sustainable production.

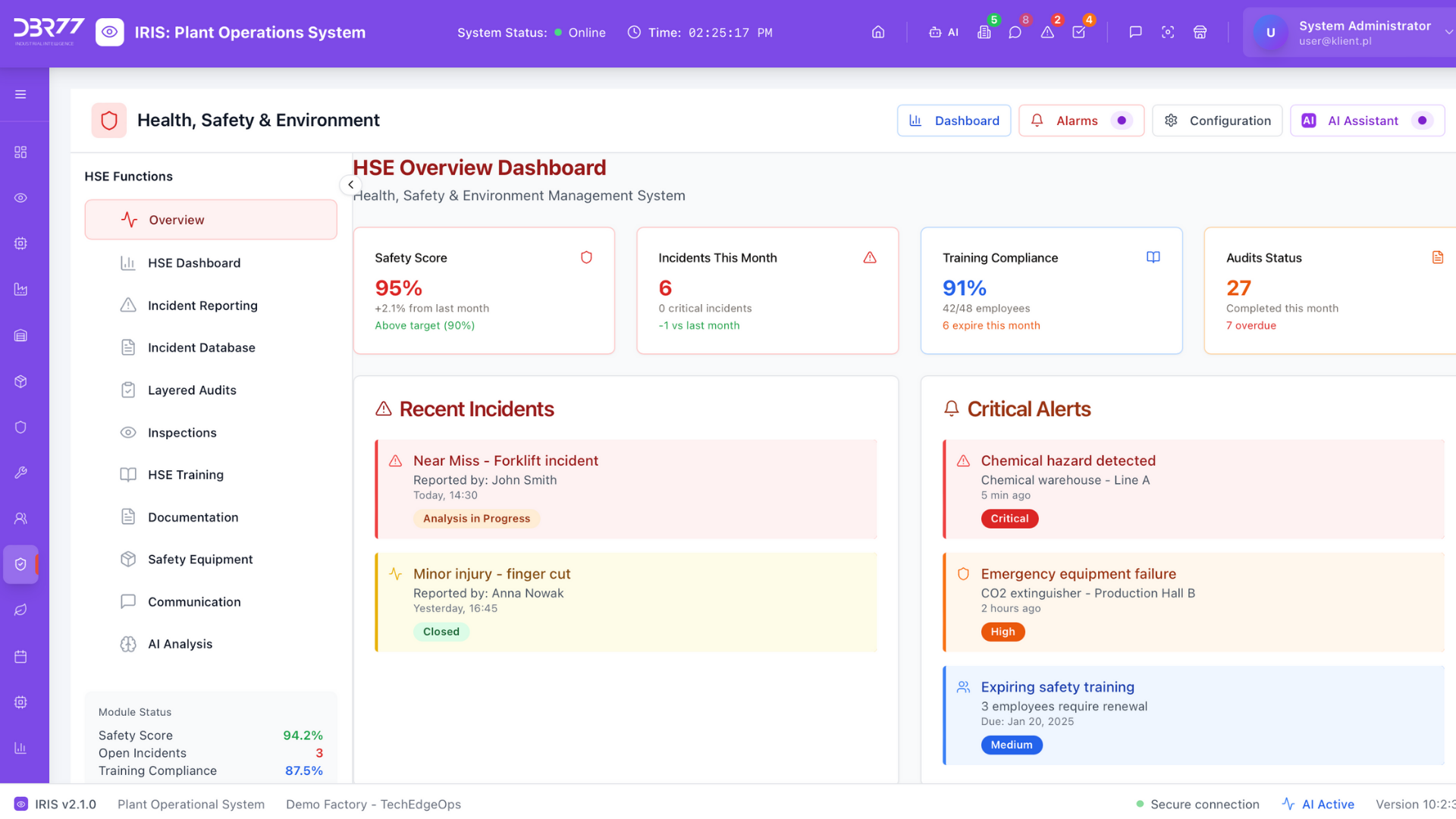

HSE – Health, Safety & Environment

Occupational health and safety management system.

- Recording of accidents and incidents.

- Monitoring of environmental conditions in the hall (noise, temperature, emissions).

- Automatic checklists and safety procedures.

- AI analyzes event data and predicts potential hazards.

IRIS77 protects employees and minimizes environmental risks.

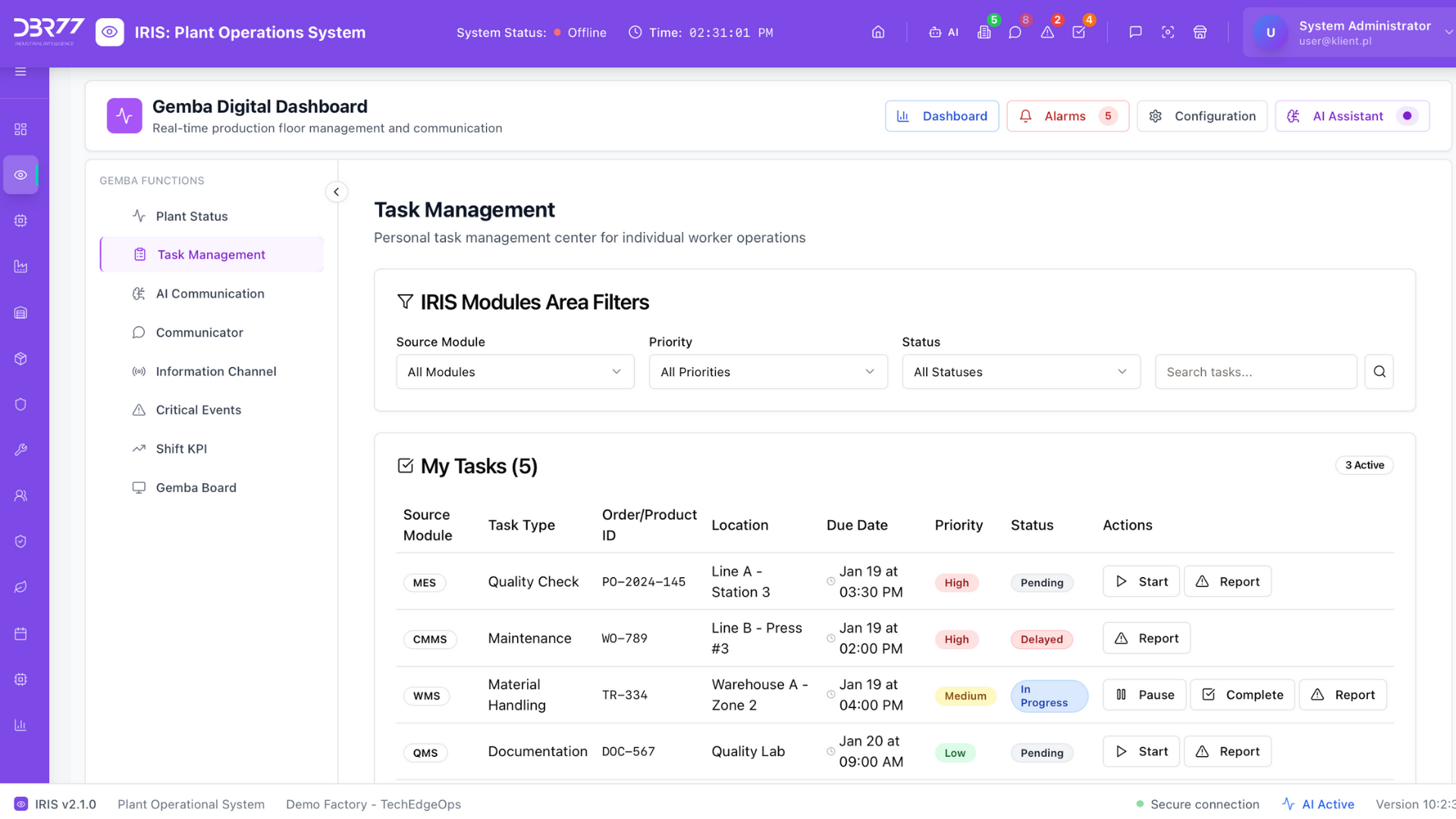

Task Management System

A central system for assigning and monitoring tasks for people, machines, robots, and transport. Every element of the factory knows what to do and when.

- Automatic generation of tasks based on plant logic (production, warehouse, quality, maintenance).

- Assignment and prioritization with the possibility of delegation.

- AI analyzes data and recommends optimal task allocation.

- Real-time monitoring and progress tracking.

IRIS77 turns data into tasks and tasks into results – the foundation of an autonomous factory.

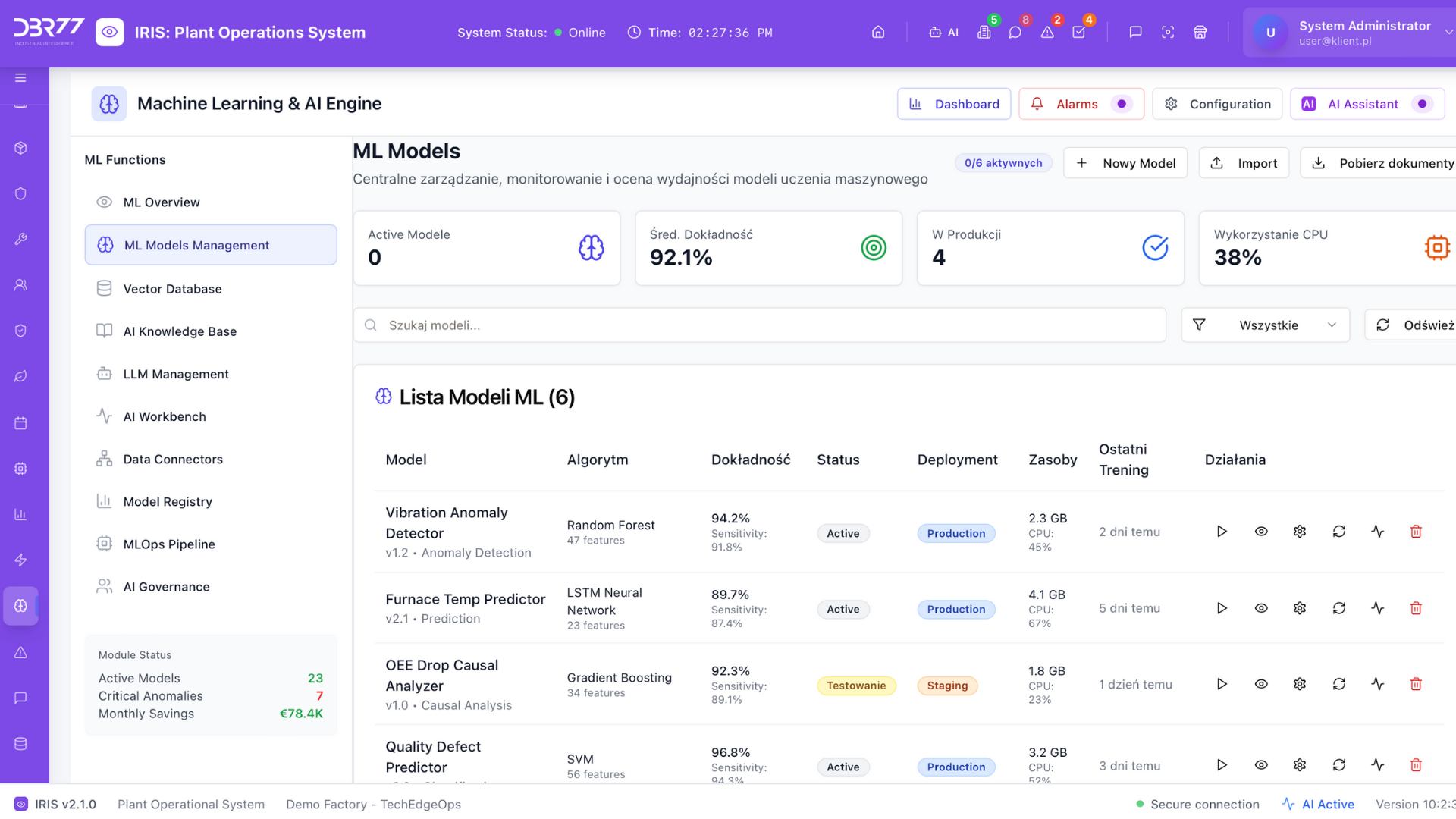

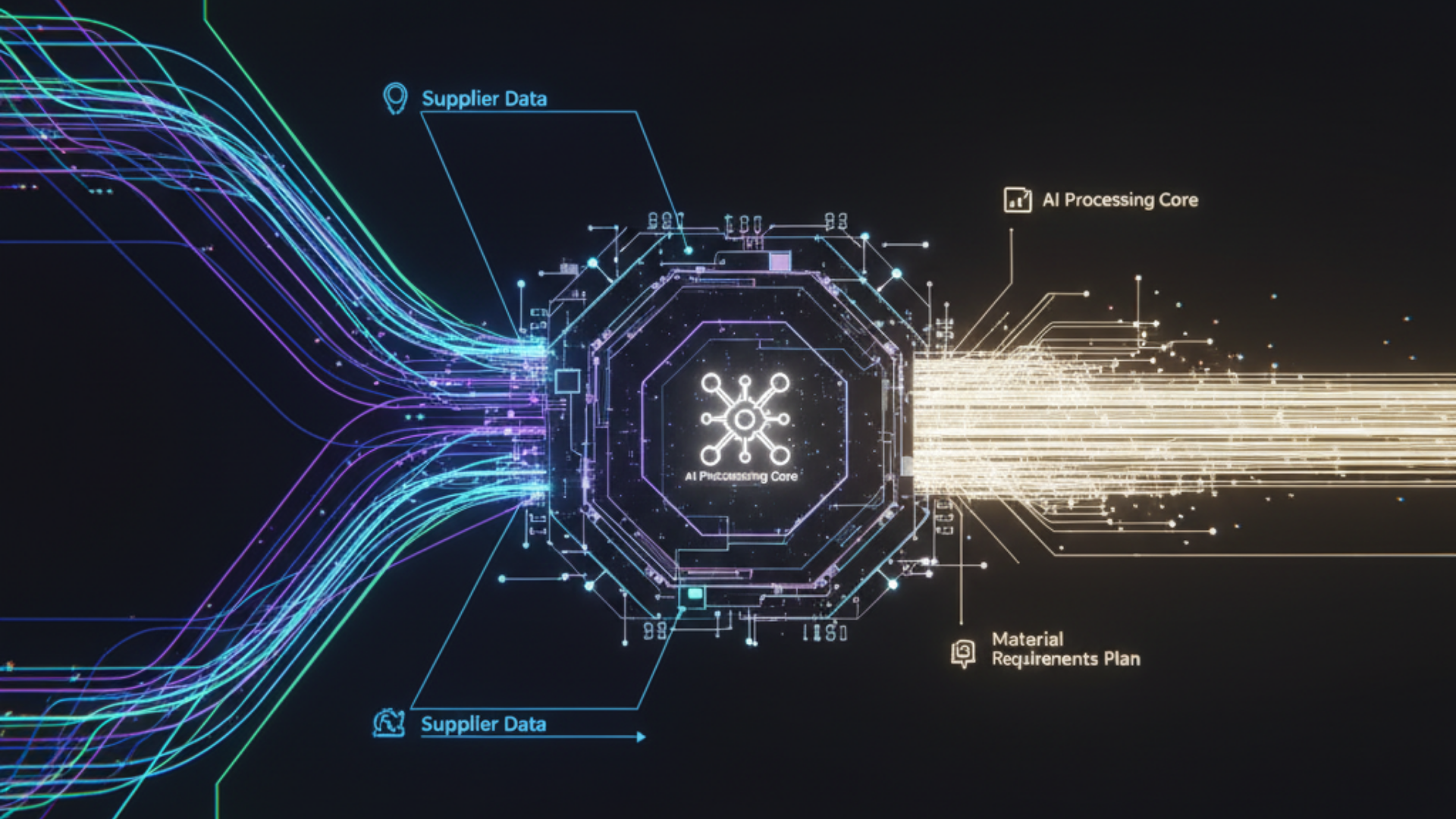

AI – Artificial Intelligence Core

At the heart of IRIS is artificial intelligence, which analyzes data and supports decisions across the organization.

- Machine learning for predicting downtime and demand.

- Digital Twin for simulating “what-if” scenarios.

- Language models (LLM) to support communication and reporting.

- Automatic recommendations for optimization measures.

IRIS77 uses AI to turn data into concrete decisions and business results.

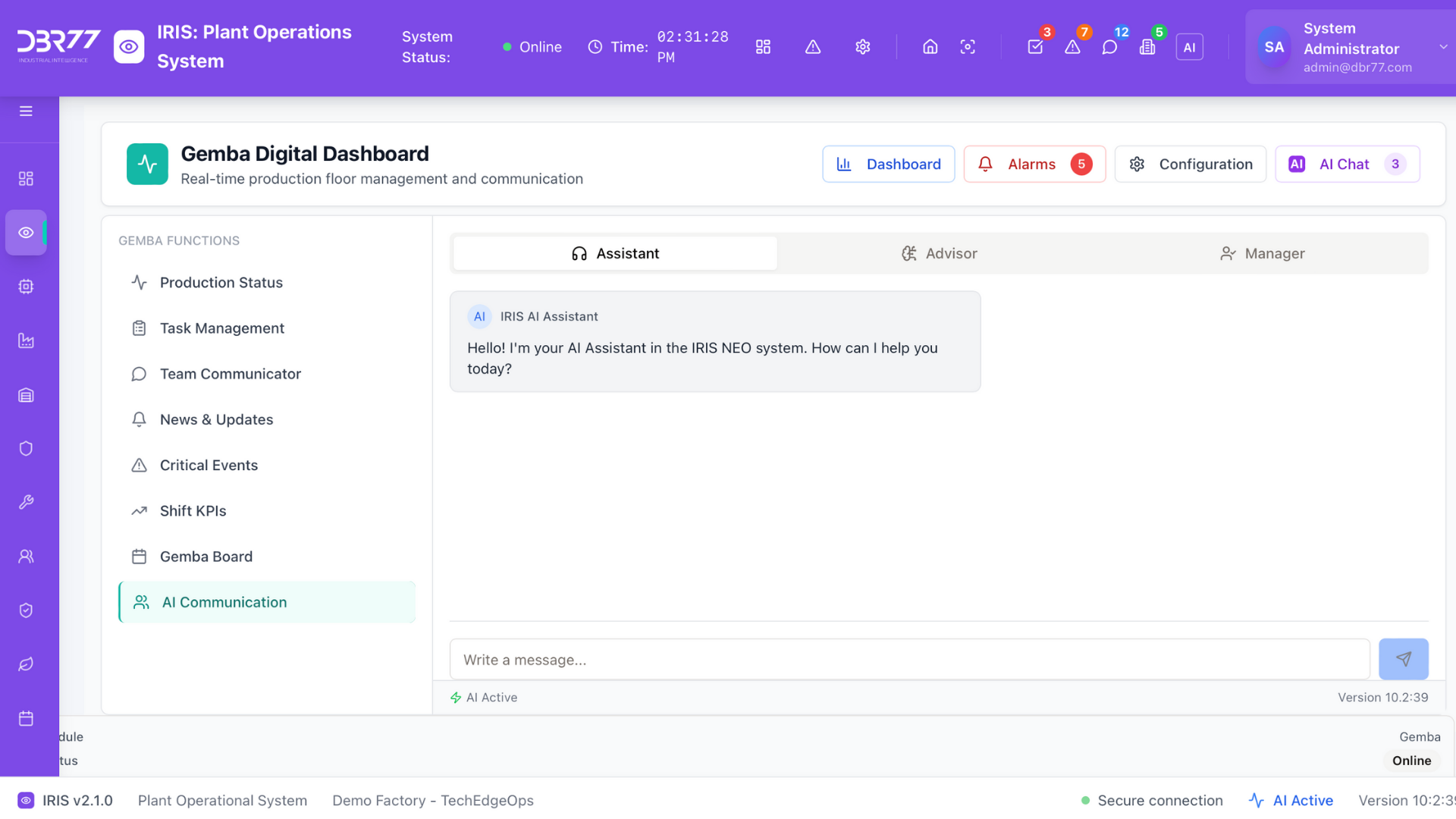

Communication within the organization

The communication system connects operators, managers, and machines in real time.

- Mobile applications and operator panels for employees.

- Integration with email, Teams, and other corporate channels.

- Task assignment and transfer based on production data.

- AI translates data into clear messages for different levels of the organization.

IRIS77 eliminates information gaps – the right information always reaches the right person at the right time.

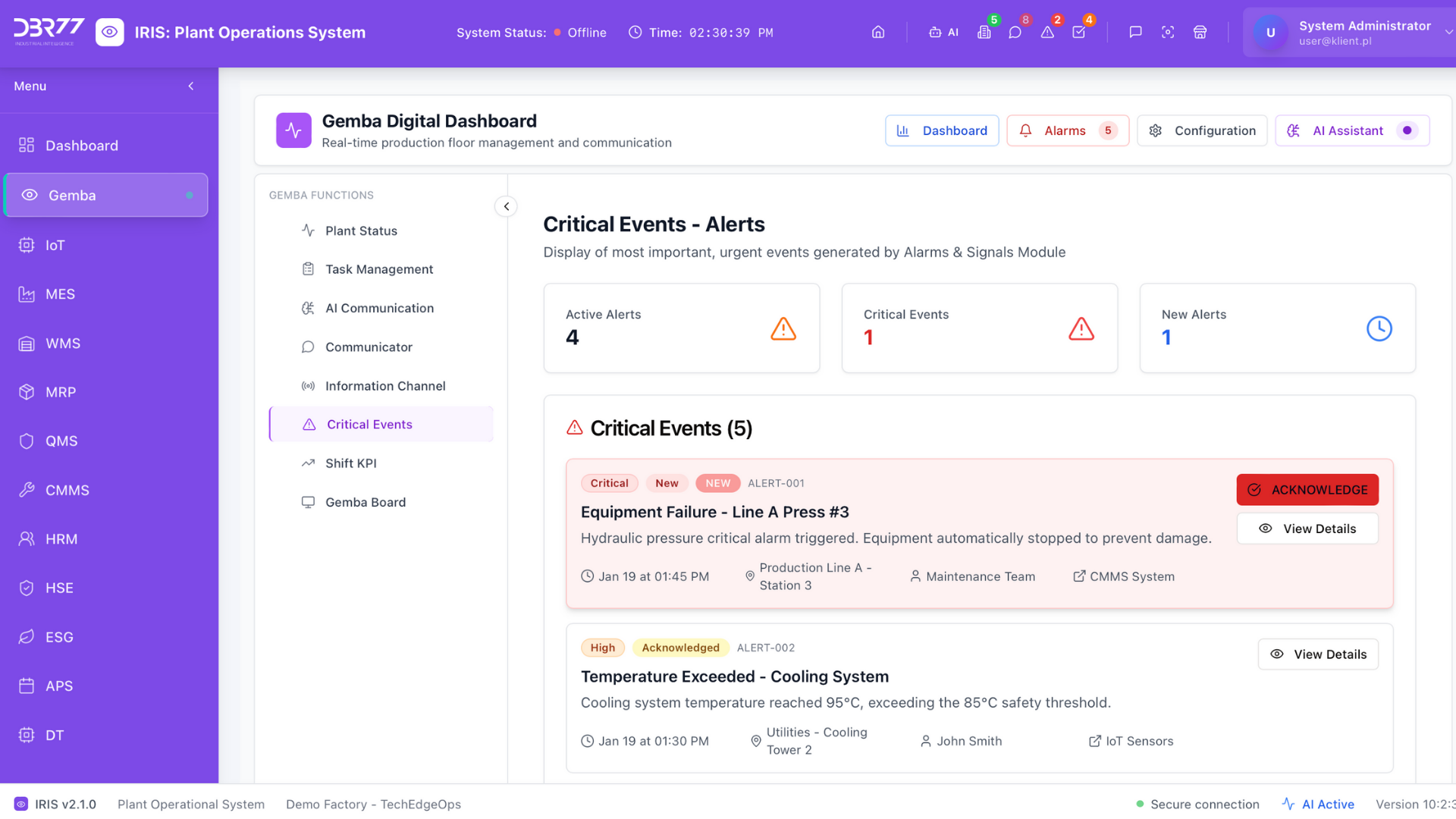

Alarm and notification system

A real-time response module that informs you about critical events.

- Alerts about machine downtime and failures.

- Notifications about quality and deadline deviations.

- Integration with IoT – alarms from sensors.

- AI classifies events and prioritizes notifications.

IRIS77 turns your alarm system into an intelligent production assistant – it warns you before a problem becomes critical.

Why is artificial intelligence a foundation rather than an addition in IRIS?

IRIS was designed from the outset as an AI Operating System for factories. Each module of the system—from MES, WMS, and QMS, through CMMS and HRM, to Digital Twin—has its own AI component that analyzes data, formulates recommendations, and generates insights.AI in IRIS works in practice:

- The system’s recommendations can automatically create optimization tasks that are initially accepted by humans and eventually become fully automated.

- ML models learn from real-world processes and are able to optimize production in ways that were previously impossible.

- Digital Twin allows you to create simulations of plants and processes that are yet to be built, generating synthetic data also for training algorithms.

IRIS uses vector databases, so decisions are always based on current data and the specific context of a given plant.

Thanks to its extensive integration capabilities and the use of MCP (Manufacturing Communication Protocol), IRIS analyzes all process variants in their real context – connecting people, machines, and data into a single ecosystem.

As a result, IRIS not only reports, but actively controls factory optimization, leading it step by step to full autonomy.

See how IRIS77 can solve your challenges

Benefits in numbers

How much does it cost? – Transparent pricing model

IRIS operates in a SaaS model scaled to the size and needs of your organisation.

- Start– for several users and one module. Ideal for starting your digital transformation in a small area.

- Growth– add more processes, modules and users as your needs grow.

- Enterprise– full transformation and global implementation, with an on-premise option for strategic data.

You only pay for what you actually use. As the system grows, all customers benefit from new features and innovations.

Translated with DeepL.com (free version)

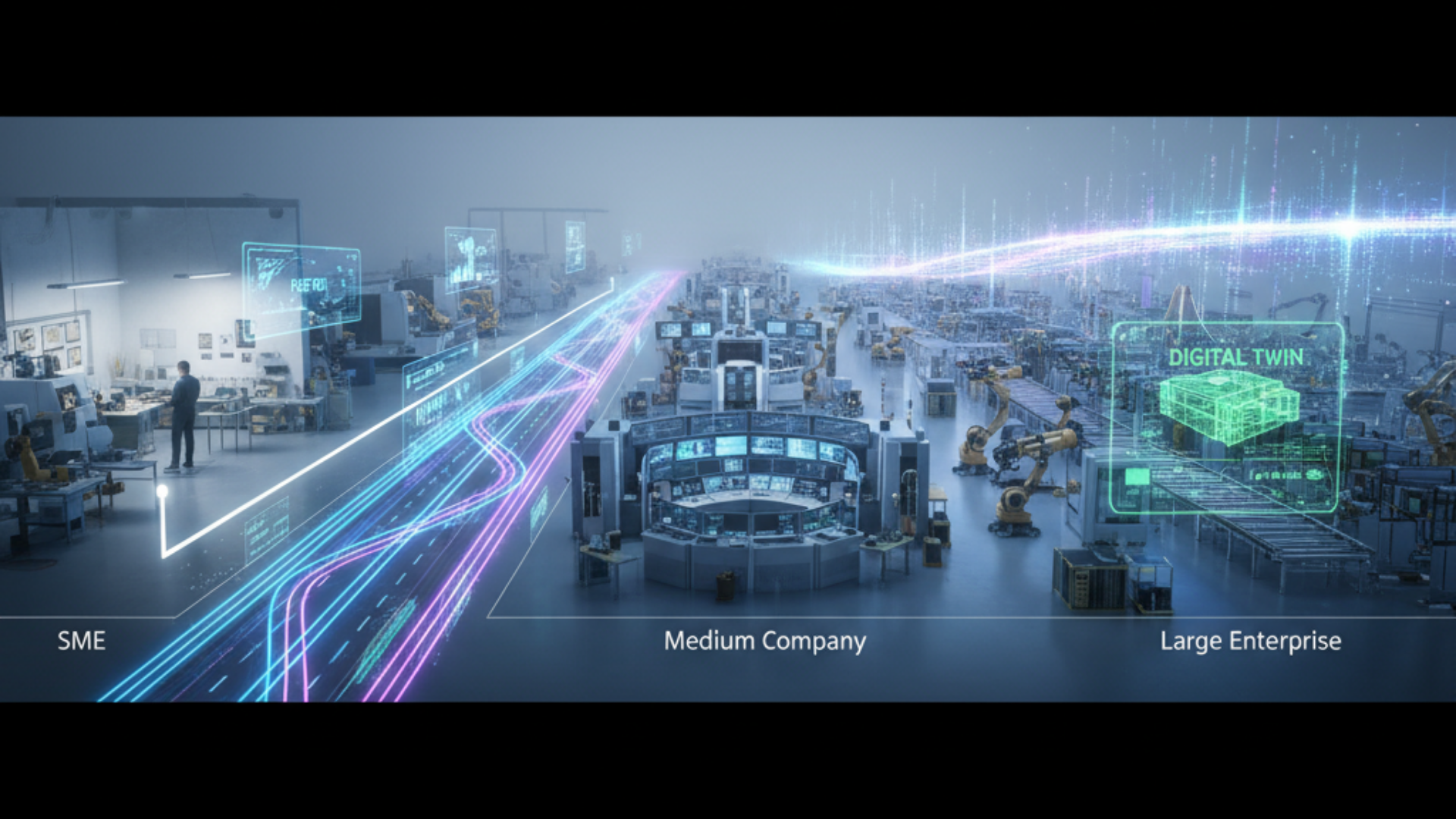

For which companies is IRIS intended?

IRIS supports the development of manufacturing companies at every stage of digitization:

- SMEs – they start with us with simple implementations, quickly achieve ROI, and at the same time grow in knowledge and digital competencies.

- Medium-sized companies – gain full control over their data, manage production precisely, and systematically improve operational efficiency.

- Large enterprises and corporations – use the most advanced tools: Digital Twin, APS, and AI to scale, standardize, and develop autonomous factories.

IRIS is the path to your company’s growth – from the first steps in digitization to full production autonomy.

IRIS supports key roles in the production plant and at headquarters:

- SME owner – fast ROI, full control over costs.

- Production manager – real-time data on OEE, KPIs, and downtime.

- Maintenance Department – failure prediction and tasks for technicians.

- CFO – transparent costs and ROI on every investment.

- CTO – secure implementation and integration with ERP/IT-OT.

- Corporate Plant Manager – standardized data for reports to headquarters.

Why now?

- The market won’t wait– customers expect flexibility and immediate delivery. Whoever responds faster wins.

- Technology gives you an advantage– factories that implement AI earlier will gain lasting dominance over their competitors.

- AI is changing the rules of the game– digital transformation is no longer the future, it is the present.

Your competitors are already investing. Don’t let them get ahead of you.

Schedule a demo and see how IRIS can transform your production.

What does implementation look like? – “Zero risk, full scalability”

1. Small start – quick launch

The first step is a simple entry into the world of IRIS – you start with a single line, workstation or process and see the results immediately.

- Module installation in days, not months.

- Intuitive applications for operators and managers.

- First OEE indicators available immediately.

Translated with DeepL.com (free version)

2. Initial data – immediate value

You will see a real return on your investment within the first few weeks. Real-time data changes the way decisions are made.

- Real-time monitoring of machines and processes.

- AI identifies losses and suggests quick improvements.

- Savings and better planning from the first month.

3. Expansion – step by step

IRIS grows with your company – new modules and processes are added at a pace that you choose.

- Scaling from a single module to an entire factory.

- Seamless integration with existing systems.

- Full control over scope and costs.

4. AI and Digital Twin – intelligence development

Over time, IRIS moves from observation to autonomous optimisation. AI and Digital Twin suggest the best decisions.

- Analysis and simulation of ‘what-if’ scenarios.

- Automatic generation of optimisation recommendations.

- Synthetic data supporting future innovations.

5. Autonomous Plant – a vision of the future

The final stage is a factory that learns on its own and operates virtually autonomously.

- Full automation of task and process management.

- Continuous optimisation based on real-time data.

- An unbeatable competitive advantage.

FAQ

How does IRIS differ from MES, WMS, or ERP systems?

IRIS is a Plant Operation System (POS) that combines all processes into a single ecosystem. MES, WMS, and QMS are only elements of it—IRIS integrates them into a single whole and adds a layer of AI.

Does implementing IRIS involve high risks and costs?

No. IRIS operates on a SaaS model and is implemented in modules. You can start with a single line and scale the system gradually, without the risk of multi-million dollar investments.

Does IRIS integrate with my ERP (SAP, Oracle, Comarch, Dynamics)?

Yes. IRIS does not replace ERP, but connects to any system, providing operational data to the financial and administrative layer of ERP.

How quickly will I see results after implementation?

The first results (e.g., reduction in downtime, increase in OEE) appear within a few weeks of implementing the IoT and task management module.

Is my data secure?

Yes. IRIS works both in the cloud (SaaS) and on-premise. Critical data and AI models can remain within your infrastructure.

Is IRIS suitable for small businesses?

Yes. IRIS can be implemented even in a company with a few users and a single production line, and then developed alongside the organization.

Is IRIS ready to work with robots and automation?

Yes. IRIS manages people, machines, processes, and in the future also robots and humanoid robots, creating a fully autonomous plant.

News

Case Study: How DBR77 Marketplace Stabilized Logistics for a Tier-1 Automotive Supplier (Ficomirrors)

In the automotive industry, where "just-in-time" production is the standard, material flow stability is the ultimate currency. Discover how...

How has the direction of robotization changed over recent years?

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes....

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely...