Without full visibility into production processes, companies make decisions based on incomplete or outdated information-leading to wasted time, resources, and money. Real-time access to key data like OEE (Overall Equipment Effectiveness) and cycle times is now essential for effective manufacturing management. In this post, we’ll explain why real-time data matters, how IoT and virtual dashboards are transforming production oversight, and how DBR77 supports this new level of transparency.

Why Is Process Visibility So Important?

When you lack up-to-date data, operational problems are often detected too late-sometimes only after significant losses have occurred. Full process visibility enables:

- Ongoing monitoring of production performance

- Rapid identification of downtime, errors, and bottlenecks

- Reliable planning and forecasting

With real-time transparency, you can respond to issues as they happen, not just analyze the consequences after the fact.

How IoT Collects OEE and Cycle Data

IoT (Internet of Things) uses sensors mounted on machines to gather information about:

- Machine operating and downtime

- Number of units produced and rejected

- Average cycle times

This data is automatically sent to analytics systems, where OEE and cycle times are calculated and visualized in real time. The result is a live, accurate picture of what’s happening on the shop floor-no more waiting for manual reports or discovering problems after they’ve grown.

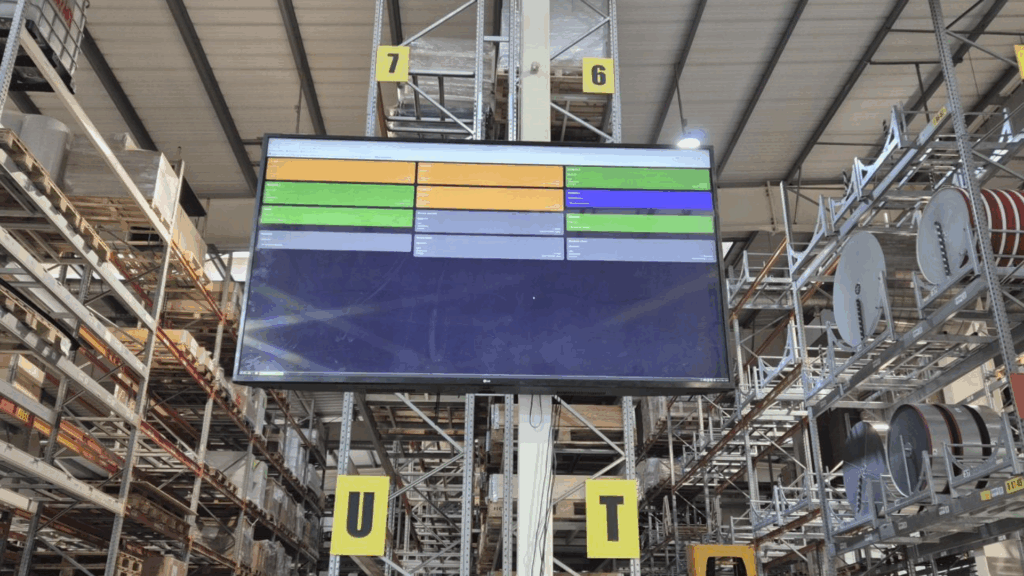

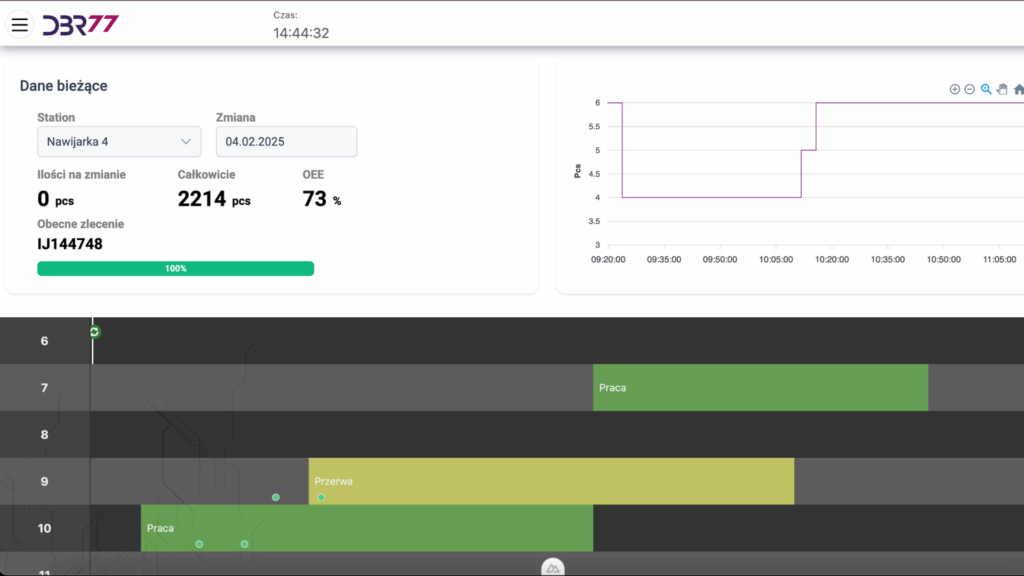

The Role of Virtual Dashboards

Virtual dashboards present key production indicators in a clear, visual format. Managers and operators can instantly track:

- Real-time OEE

- Machine status (running, stopped, failure)

- Critical quality and quantity metrics

Dashboards enable quick diagnosis and decision-making, removing the need for time-consuming manual reporting. With all the essential data in one place, teams can act faster and more confidently.

Real-World Results from Enhanced Visibility

- An automotive parts manufacturer increased OEE by 12% in six months after implementing IoT sensors and dashboards.

- A beverage plant reduced average downtime by 20% through real-time machine cycle monitoring.

- A textile factory improved response speed to breakdowns by 30% after deploying virtual dashboards.

How DBR77 Delivers Real-Time Data

DBR77 integrates data from its own IoT sensors and existing production systems, making it instantly available through advanced dashboards. The platform automatically calculates OEE, cycle times, micro-downtime, and other key operational metrics. With the use of a digital twin, DBR77 can even simulate future scenarios based on current data, supporting proactive decision-making and continuous improvement.

Benefits of Full Process Transparency

- Faster detection and elimination of operational issues

- Increased efficiency for production and maintenance teams

- More accurate production and resource planning

- Better forecasting of costs and delivery dates

- Stronger customer and partner trust thanks to operational stability

Challenges in Data Integration

Achieving real-time visibility isn’t without its hurdles. Companies may face:

- Different communication standards between older and newer machines

- The need for robust data security (encryption, access controls)

- Adapting workflows and team habits to leverage live data instead of relying on periodic reports

Practical Steps to Boost Visibility

- Identify which KPIs to monitor (e.g., OEE, cycle time, downtime)

- Install IoT sensors on key machines and lines

- Deploy a data collection and analytics platform

- Build virtual dashboards tailored to user roles (operator, manager)

- Train teams to interpret and use data in daily operations

- Continuously refine metrics and processes based on ongoing data analysis

Impact on Decision-Making

With real-time, fact-based insights, decisions become faster, more precise, and less risky. Production management becomes more agile and resilient to market changes, giving companies a competitive edge through better process control and adaptability.

Ready to see your entire production process in real time?

Discover how DBR77’s IoT platform and digital dashboards can give you the transparency and control you need to optimize your operations. Visit our IoT DBR77 solutions page to learn more.

Finally, we invite you to listen to our podcast, where we discuss the latest trends and practices in data-driven manufacturing. Subscribe to us on your favorite streaming platform so you don’t miss future episodes where we share inspiration, expert interviews and practical tips for production leaders.

Subscribe to stay up to date

https://factoryonair.buzzsprout.com

Book a free session with a DBR77 expert and see how our platform works in action.

Let’s talk: Book a meeting

Until we hear from you!