Problem We Solve

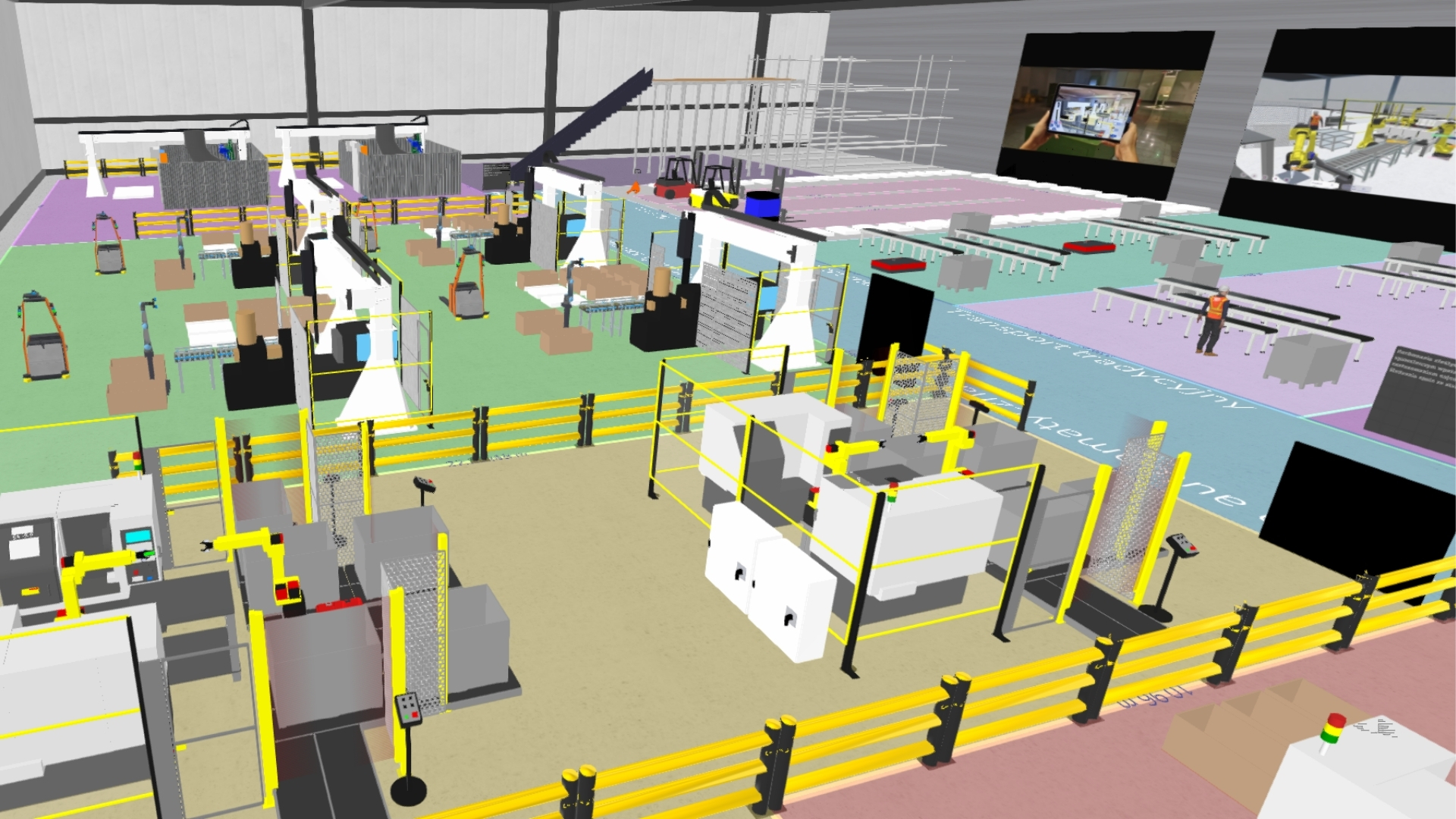

Modern production facilities and logistics centers must continuously improve their work and operational organization. However, the lack of precise data and analysis tools often limits the ability to optimize effectively. The DBR77 Digital Twin provides complete insight into process performance, enabling managers to make quick, data-driven decisions, both during optimization and daily operational management.

Results in Numbers

DBR77 Solutions

DBR77 offers comprehensive support to managers in the process of improving plant efficiency, among other things:

1. Process Analysis and Optimization

DBR77 Digital Twin enables detailed analysis of machine performance and processes, identification of inefficiencies, and simulation of optimization actions to maximize productivity.

2. Preparation of Value Stream Mapping (VSM) for Different Scenarios

DBR77 enables the creation of value stream maps (VSM) for various operational scenarios, allowing for more flexible and precise resource planning and the identification of potential areas for optimization.

3. Resource and Material Flow Planning

The simulation of flow and optimization of warehouse space and production workstations help eliminate bottlenecks and improve resource utilization, enhancing operational efficiency.

4. AI-Based Decision Making

AI-driven analysis of operational data supports accurate strategic and operational decision-making, enabling adaptation to dynamic changes in production conditions.

Advanced Simulation Environment

The DBR77 Digital Twin simulation environment enables stochastic event simulations based on various scenarios. The system generates comprehensive data sets by automatically adjusting scenario assumptions, identifying optimal decision solutions for specific conditions. AI assistants further support managers by analyzing complex tasks in real time and suggesting critical insights, enabling swift decision-making and dynamic action adaptation to changing conditions.

Why Choose DBR77?

Ease of Use and Quick Implementation

After just one hour of training, managers can effectively utilize the DBR77 platform, maximizing resource and operational efficiency. Its intuitive interface allows seamless integration into daily workflows.

Advanced Stochastic Simulation Methodology

The system precisely simulates real production processes, taking into account variability and inefficiencies. This enables the accurate identification of areas for improvement and a detailed analysis of the impact of optimization measures. It allows for in-depth analysis and effective optimization planning. DBR77 focuses on efficiency indicators such as OEE to maximize operational performance.

News

Case Study: How DBR77 Marketplace Stabilized Logistics for a Tier-1 Automotive Supplier (Ficomirrors)

In the automotive industry, where "just-in-time" production is the standard, material flow stability is the ultimate currency. Discover how...

How has the direction of robotization changed over recent years?

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes....

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely...