Nothing appeals to the imagination like the experience of completed projects. See what effects our products have had on HSV Poland. By using our Robot Platform (marketplace), they chose the optimal solutions (HSV Poland case study).

Case description

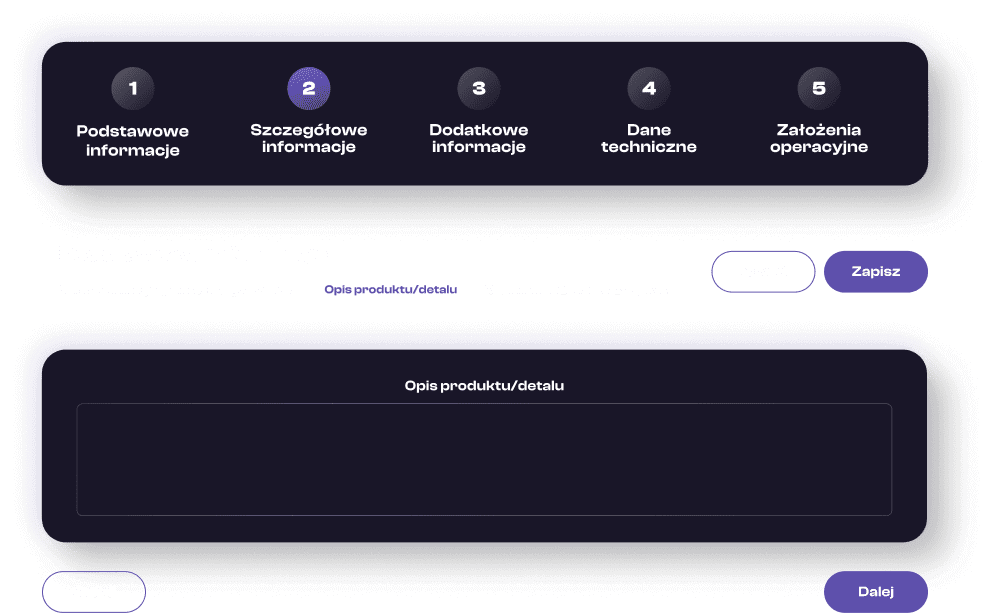

The project involved the delivery of an automated line for quality control and packaging of EPP plastic products. At that time, the first enquiry appeared on the Platform, containing all the necessary information regarding the technical requirements needed by the integrator.

Therefore, the solution concept prepared by the integrator Redhawk included a visualisation with a simulation prepared in Studio 3D. In addition, it also included an operational analysis and a financial analysis.

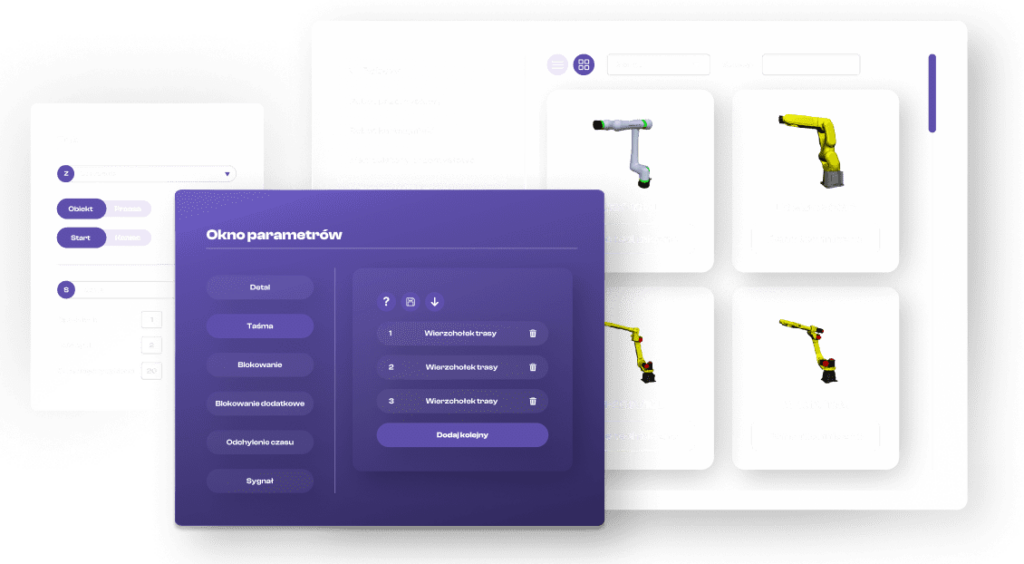

The visualisation showed the transport of the product through the dryer to the first robotic station, equipped with a vision system for locating fittings. Each time, the robot received coordinates for picking up the product. Then, it moved to the station for quality control of the product dimensions.

The compliant product was placed on a scale, after which a second robot picked up the moulding and packed it into a container according to the appropriate pattern. Thanks to animation in Studio 3D on the DBR77 Platform, a line cycle time of less than 120 seconds was confirmed for all product codes included in the project.

Suppliers involved in the project:

Fanuc

Of course, the slim-profile M-10iD/8L model is ideal for small workstations. In addition, the through-arm, wrist and robot body allow for easy and reliable compressed air cable routing. In terms of parameters: the robot has a reach of 2032 [mm] and a permissible load of 8 [kg].

Keyence

The Keyence CV-X470F vision system, controlled by a Keyence controller containing control software, proved to be excellent.

Secomea

The remote management solution for robotic and automated workstations certainly played an important role. As a gateway to the robotic workstation, the SiteManager router makes all devices available to remote users via the central GateManager server.

Results and conclusions

In summary, thanks to the DBR77 Robot Platform, an automated quality control and packaging line for EPP products was successfully implemented at HSV Polska. The project involved cooperation with the integrator Redhawk, which developed 3D visualisation, operational and financial analysis. The automation included vision systems for precise product location, robotic quality control and efficient packaging. The 3D simulation confirmed a cycle time of less than 120 seconds for all product codes, guaranteeing efficiency and reliability.

We invite you to familiarise yourself with our solutions and to contact us.

More about our marketplace – the Robot Platform – at: https://dbr77.com/marketplace/

Client’s website: https://www.hsv.pl/

See also a film about Marketplace from the DBR77 Stage at the ITM trade fair: