The Problem We Solve

Industrial education requires access to practical tools that prepare students for the realities of the modern job market. In the era of digitalization and automation, universities often face challenges in effectively teaching students how to manage production processes, analyze production capacity, or design robotic solutions. DBR77 provides a digital environment that combines advanced industrial functions with user-friendly design, making it an ideal tool for educational purposes.

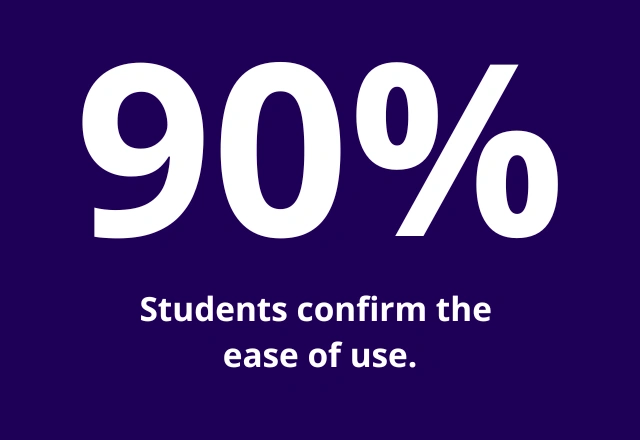

Results in Numbers

DBR77 Solutions

DBR77 offers comprehensive educational support to universities and institutions training future industry leaders:

Access to a Digital Work Environment

Universities gain access to realistic simulation tools. With AR and VR technology, students experience production processes in practice without leaving the classroom.

Dedicated Courses and Training

Specialized educational modules cover factory design, capacity analysis, and process automation. These programs prepare students for real challenges in modern industry, developing their technical and analytical skills.

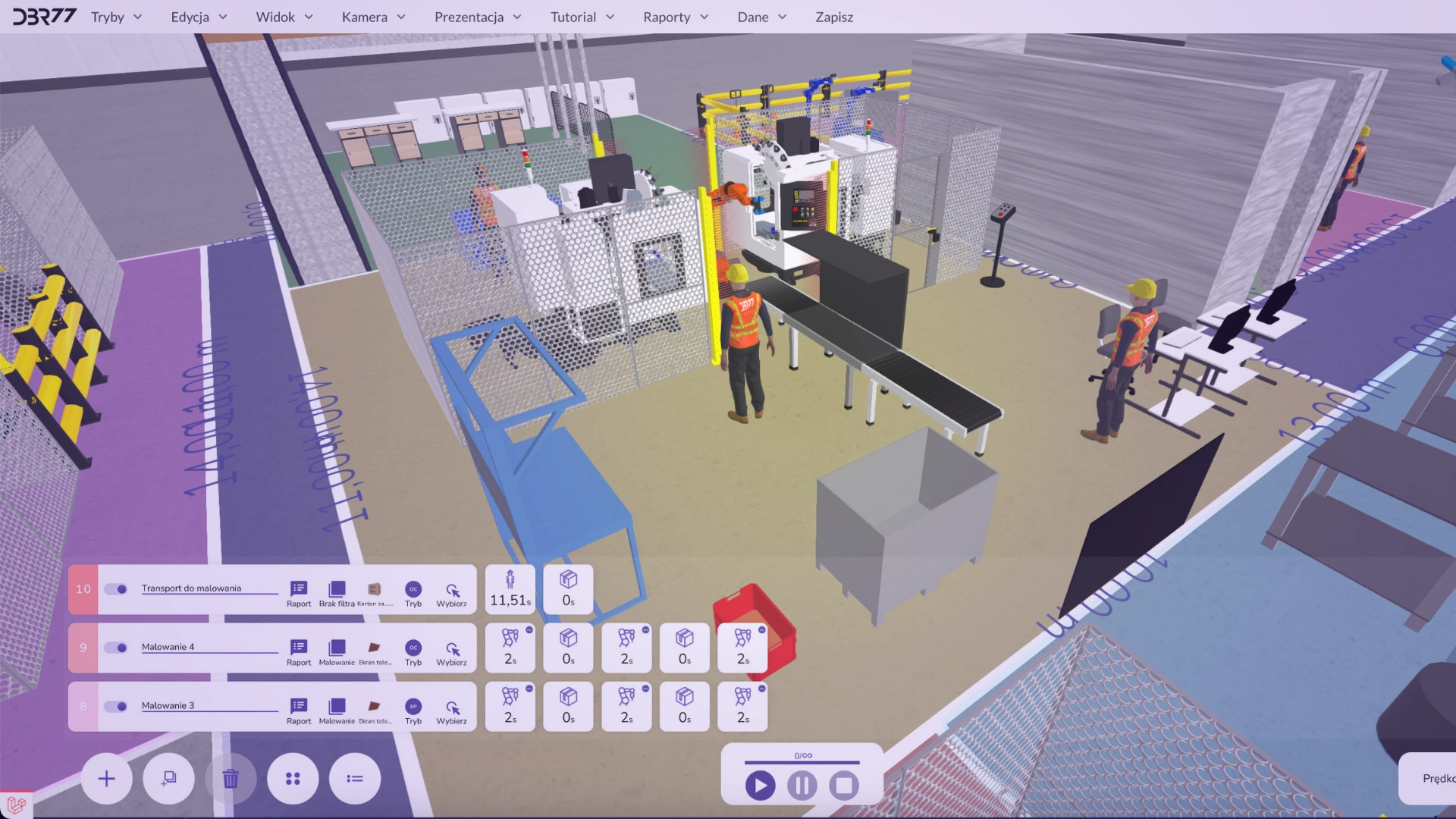

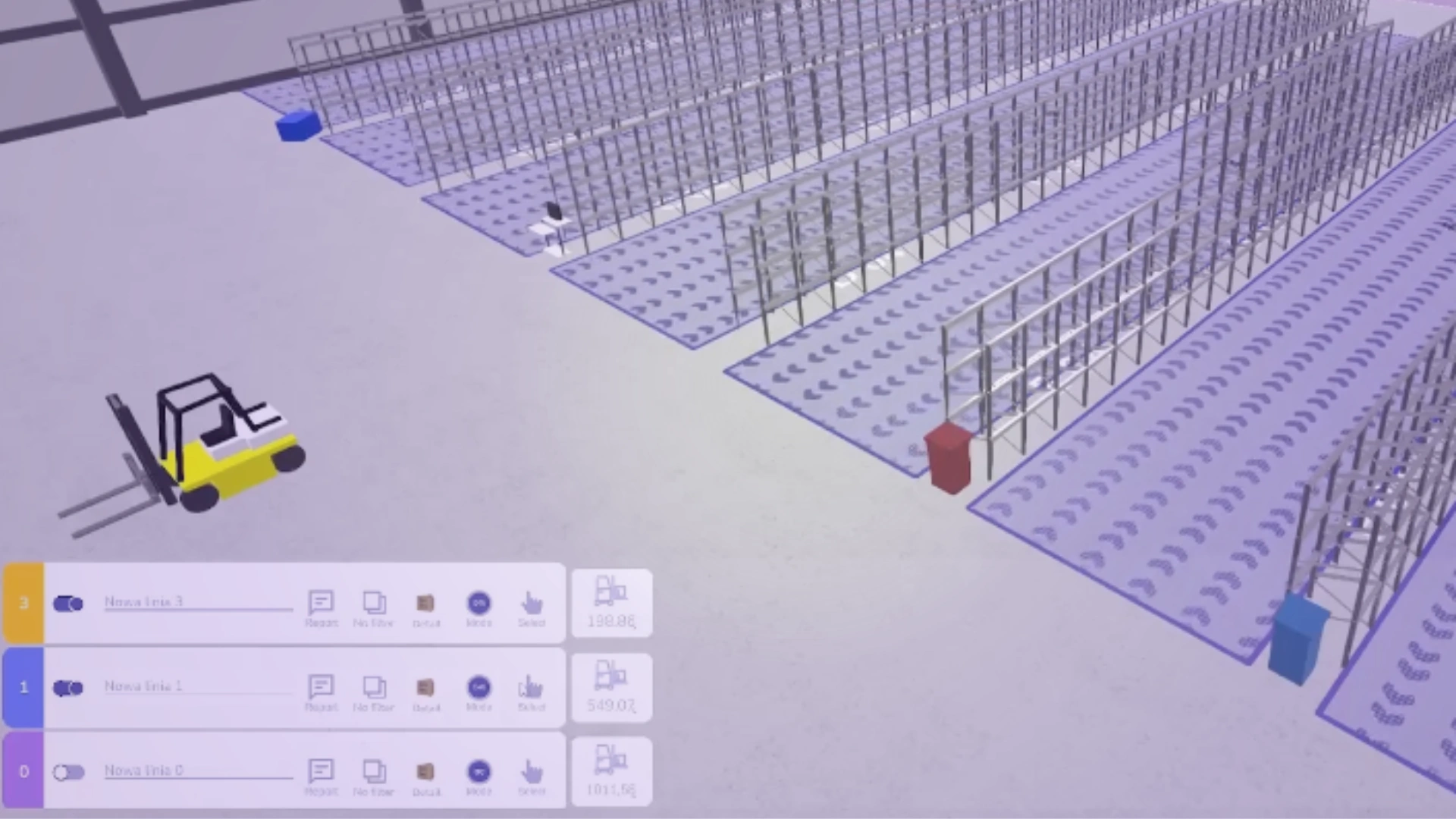

3D Studio for Simulation and Visualization

Our advanced studio allows students to design, test, and analyze manufacturing plants in a virtual environment. This tool also supports thesis projects, offering hands-on experience in optimizing production processes.

Advanced DBR77 Technologies for Education

DBR77 is an intuitive educational tool for technical universities and industrial programs. IoT and Digital Twin technologies enable process modeling, while the 3D Studio provides realistic simulations. VR/AR supports the analysis and design of production layouts, developing hands-on skills.

Why DBR77?

An Industrial Environment Designed for Education

DBR77 is designed for simplicity and accessibility, allowing students to quickly understand and utilize modern industrial solutions during both theoretical and practical classes.

Comprehensive Access to Advanced Features

Students have access to technologies such as Digital Twin, IoT, and 3D Studio. These tools enable simulation, analysis, and testing of real industrial processes, preparing participants for the challenges of modern industry.

Training and Courses Tailored to University Needs

The DBR77 platform offers ready-made educational modules that can be adapted to academic curricula. The courses cover process analysis, work optimization, and technology management, equipping students with practical skills essential for their professional careers.

Case studies

Berlin – SRH University of Applied Sciences Berlin

In collaboration with DBR77, SRH University in Berlin implemented a pioneering educational project based on Digital Twin technology. As part of this partnership, a dedicated platform was created for students, enabling them to navigate projects freely and complete practical tasks.

To effectively integrate this new technology into the learning process, instructors underwent comprehensive training on the platform’s operation. This allowed them not only to conduct lessons and exams on the platform but also to teach practical applications of the Digital Twin.

During the course, students designed production lines and processes, diagnosed errors and worked to minimize downtime. Each student created their own Digital Twin according to the instructor’s guidelines, completing a series of practical tasks on it.

With the advanced capabilities of the Digital Twin DBR77 and the 3D studio work of the DBR77, participants had the opportunity to:

– improve the efficiency of production lines,

– analyze process performance,

– reduce design errors,

– simulate events,

– design and edit production lines based on real data,

– observe their projects in virtual (VR) and augmented reality (AR).

The entire educational process, including exams, was conducted using DBR77’s Digital Twin technology. Additionally, as part of the collaboration, Dr. Piotr Wiśniewski, CEO of DBR77, delivered a lecture titled “Digital Leader in a Digital World,” introducing students to the challenges and opportunities of digital transformation.

News

DBR77 Signs Strategic MoU with Saudi Ministry of Industry to Support “Future Factory” Program and Vision 2030

Riyadh / Berlin / Warsaw / Charlotte - December 2025. It is a defining moment for our global expansion. DBR77 has officially signed a strategic...

IEX 2025 Recap: DBR77’s Historic Charlotte Launch Ignites “From Lean to AI” Conversation

Thursday, October 16th, 2025, marked a historic milestone for DBR77. Inside a packed PORTAL Atrium at UNC Charlotte, the inaugural IEX: Innovation...

More than a Pin on the Map: Why DBR77 chose North Carolina as Our Gateway to American Manufacturing

This week, our leaders laid out a bold vision. Torian Richardson spoke of building a true Makers Network, and our CEO, Piotr Wiśniewski, Ph.D.,...