Problem We Solve

We live in a world of immense volatility, where every production facility and logistics center operates under the pressure of short deadlines, uncertain orders, and limited resources. This new reality demands rapid responses and constant adaptation. To remain competitive, businesses must continually refine their production methods and optimize decisions in real time. But how can this be done quickly and cost-effectively?

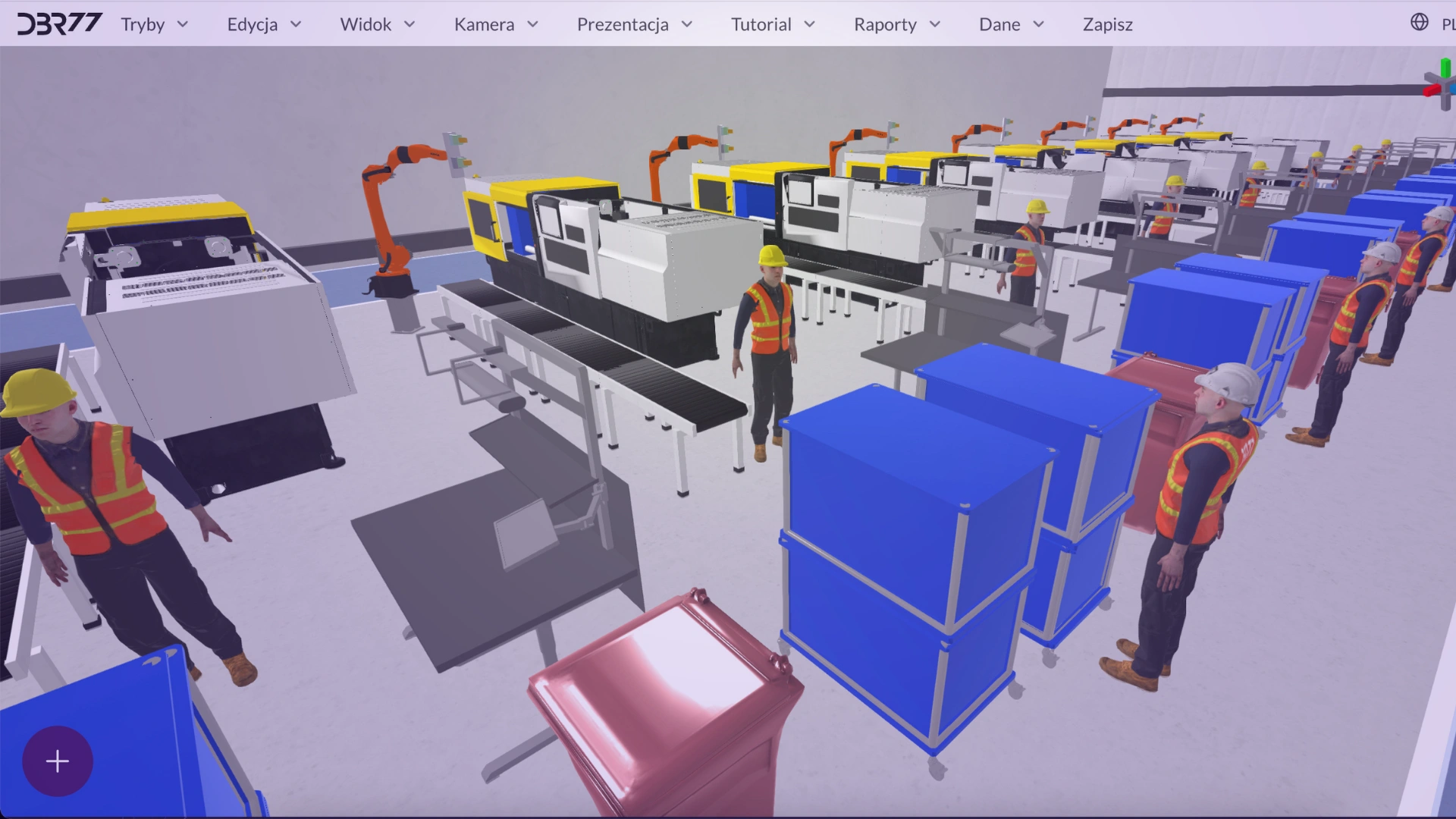

DBR77 Digital Twin – Virtual Representation of Your Operations

DBR77 Digital Twin is an advanced tool that enables precise modeling of production and logistics processes in a virtual environment. It allows you to simulate, analyze, and optimize operations, minimizing risks and maximizing efficiency. By leveraging real-time data, the Digital Twin enables the testing of various scenarios and supports better decision-making.

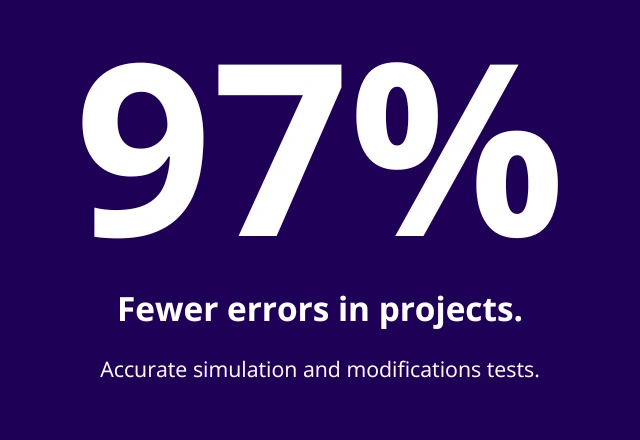

Key Benefits in Numbers

How Does DBR77 Digital Twin Work?

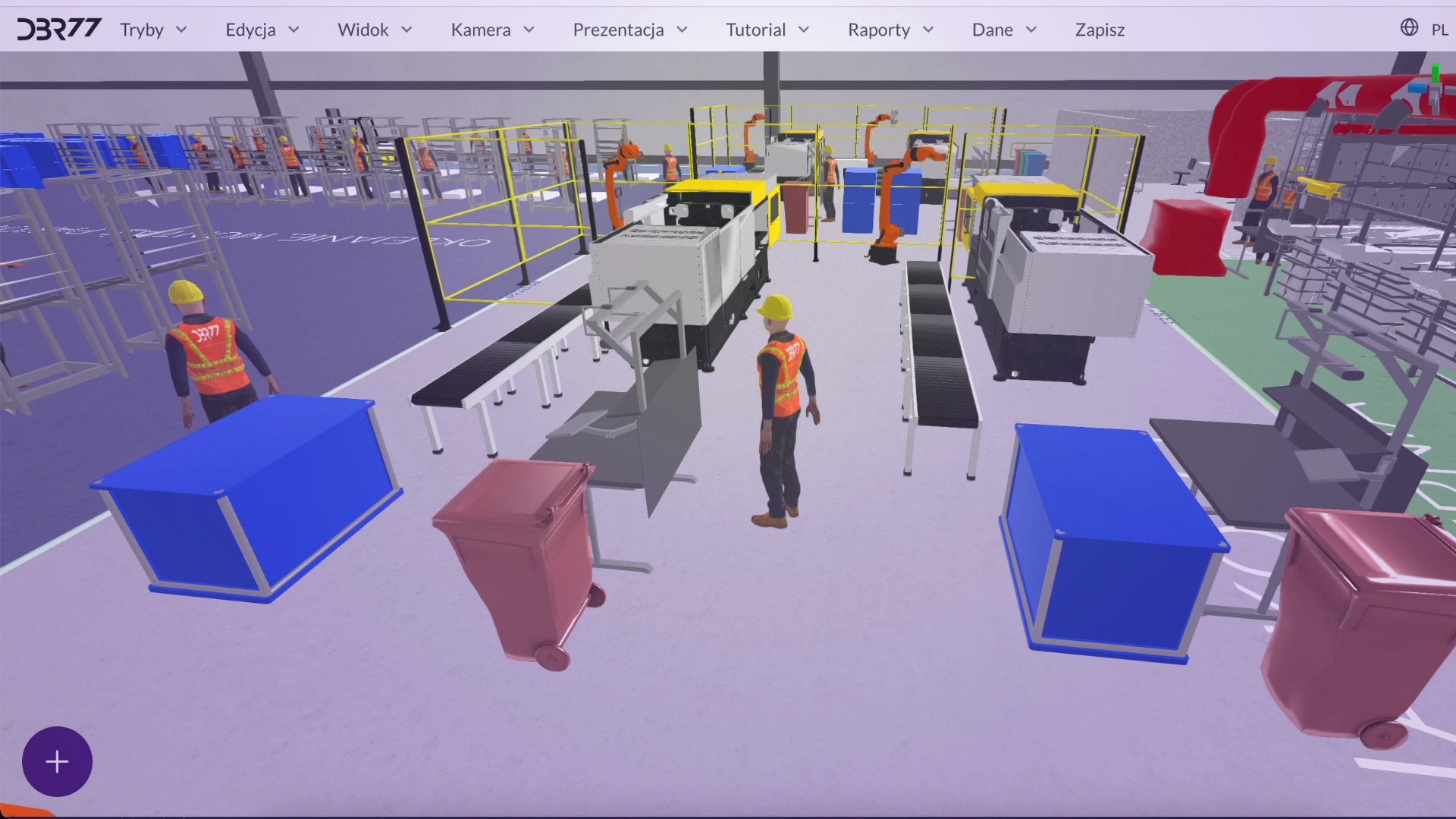

Virtual Process Representation

DBR77 Digital Twin creates a digital model of your facility, replicating machines, production lines, and resources. This enables a 3D view of operations and analysis without disrupting ongoing work.

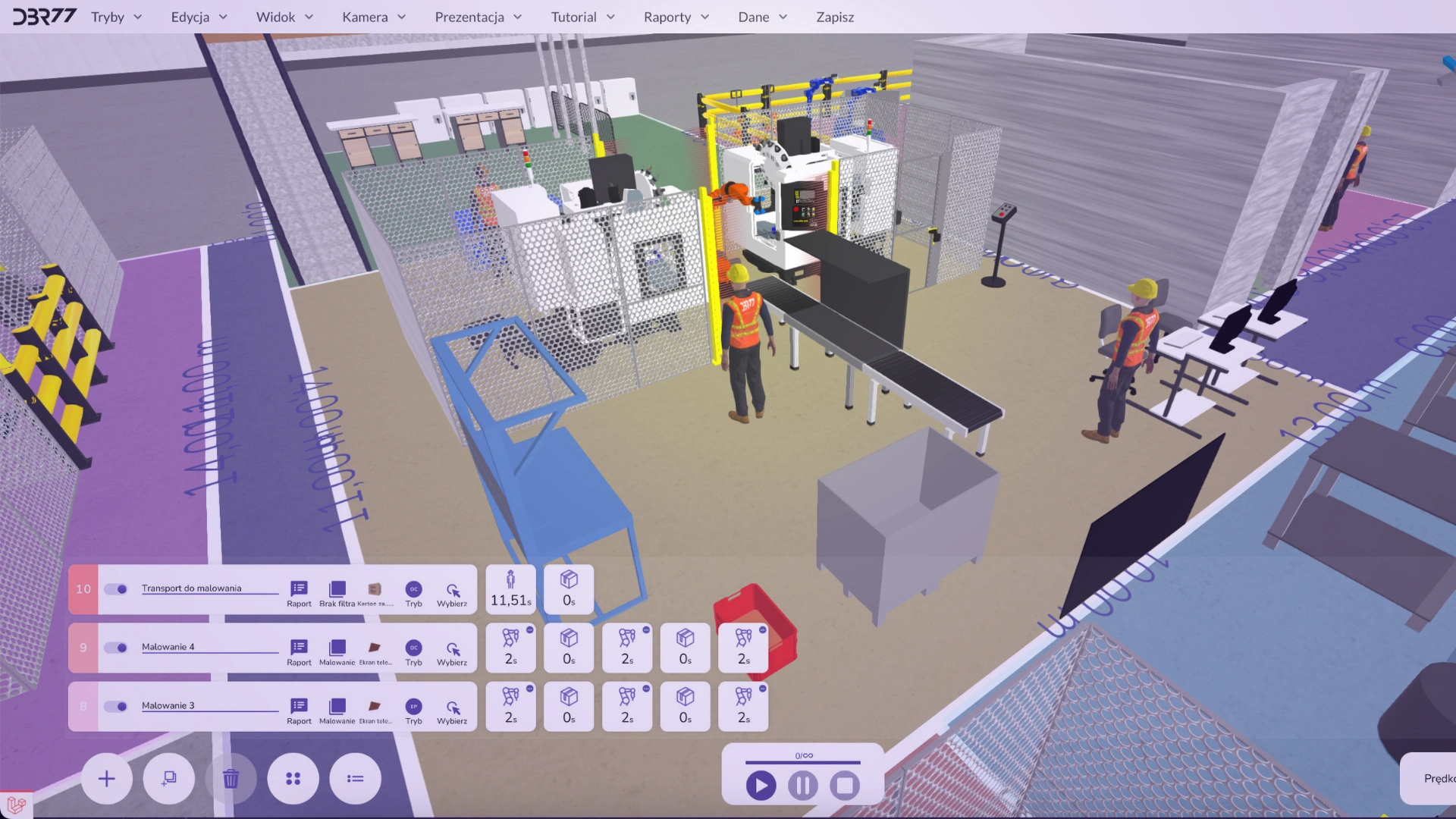

Simulation and Scenario Testing

The system simulates various scenarios, such as layout changes or testing new configurations. Artificial intelligence analyzes the effects of these changes, assessing their impact on costs and efficiency.

Optimization and Decision Automation

DBR77 analyzes data, generates reports, and supports real-time optimization, focusing on key indicators such as OEE, energy consumption, and task completion time. The system helps quickly respond to changes in resources and orders, maximizing efficiency.

Support for Digital Transformation

The platform facilitates the implementation of Industry 4.0 principles by offering tools for change management, including a digital twin, operational scenario simulations, and analytical modules that support strategic and operational decision-making. Regular updates and flexible subscriptions ensure compliance with modern standards.

Features and capabilities

1. Visualization and Capacity Analysis

DBR77 Digital Twin provides realistic 3D visualizations of production lines, warehouses, and facilities. This is a critical tool when designing new investments or making layout changes, allowing for better planning and management of operational space.

2. Dynamic Process Analysis and Simulations

The system analyzes production processes, intralogistics, and warehousing, identifying areas that require optimization. It conducts organizational scenario simulations, tests operational strategies, and supports optimization through value stream mapping (VSM) and controlled testing of changes.

3. Algorithmic Decision Support

The system supports real-time decision-making, which is crucial for facilities with high production variability. Algorithms assist in managing operations and responding to dynamic changes. The tool assesses the potential for automation and robotics, highlighting areas where investments will yield the highest benefits.

Discover how DBR77 Digital Twin can solve your challenges

Benefits of Implementing DBR77 Digital Twin

Better Planning and Risk Mitigation

Simulating various options in a virtual environment allows companies to make informed decisions and reduce operational costs. DBR77 enables safe implementation of automation and changes, eliminating risks of production disruptions and failed deployments, increasing operational efficiency and stability.

Flexibility and Digital Transformation Support

The system enables dynamic adaptation to changes in orders and resources, enhancing competitiveness. DBR77 Digital Twin implements Industry 4.0 and Lean 4.0 principles, facilitating digital transformation. As a result, companies become more innovative and better prepared for future technological challenges.

Unique DBR77 Digital Twin technology

1. Advanced Stochastic Scenario Analysis

Leveraging DBR77’s unique 3D technology, the system enables advanced scenario analysis, accounting for variables and random events, facilitating the testing of optimal solutions in a virtual environment.

2. Comprehensive Facility Analysis

DBR77 provides a full analysis of processes and material flow using mission management. The technology replicates all objects’ actions and interactions within the facility, enabling a detailed view of their behavior and efficiency.

3. Deviation Modeling

Na podstawie danych historycznych zbieranych przez IoT, bliźniak cyfrowy tworzy statystyczne modele odchyleń w zrealizowanych procesach. Symulacje mogą odwzorowywać realne nieefektywności, co pozwala dokładniej prognozować rzeczywiste warunki pracy i zwiększać skuteczność analiz.

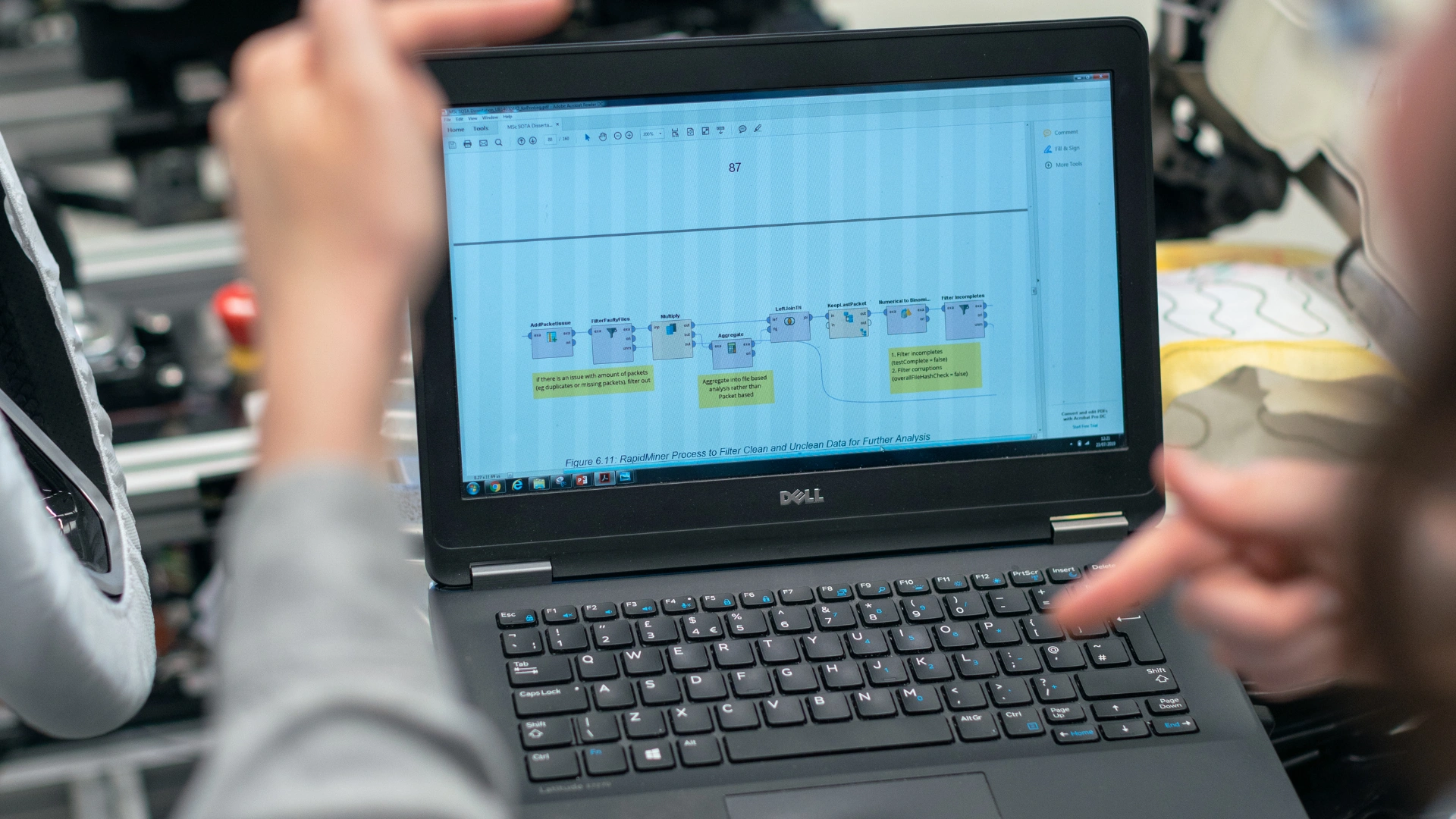

4. Artificial Intelligence

DBR77 utilizes AI algorithms, including automated scenario simulations, result analysis through language models, and machine learning for decision support. These tools assist experts responsible for production process organization and operations managers, enabling more precise and dynamic management.

Discover how DBR77 Digital Twin can solve your challenges

Why choose the DBR77 Digital Twin?

1. Ease of Deployment and Scalability

The DBR77 Digital Twin features a low entry barrier – pilot deployment requires just a few hours of training, and the system operates on a subscription-based model. The solution can be scaled across all facility areas, expanding the reach of digital management without significant upfront costs.

2. Precise Simulation of Real-World Conditions

DBR77 replicates real production and operational processes, allowing scenario testing without disrupting ongoing work. Simulations enable informed decision-making, in-depth analysis, and process optimization, resulting in cost savings and efficiency gains.

3. Versatility and Compatibility

DBR77 integrates with IoT systems and supports robotics through a marketplace offering modern automation technologies. Everything is managed from a single platform, simplifying operations and increasing adaptability in changing conditions.

4. AI-Powered Work Support

An intelligent AI assistant helps users interpret data, plan, and optimize processes. The system automates analyses and generates insights, enabling more effective operations management and long-term strategic decision-making.

News

Case Study: How DBR77 Marketplace Stabilized Logistics for a Tier-1 Automotive Supplier (Ficomirrors)

In the automotive industry, where "just-in-time" production is the standard, material flow stability is the ultimate currency. Discover how...

How has the direction of robotization changed over recent years?

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes....

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely...