Problem We Solve

The lack of real-time production floor data leads businesses to lose control over their processes, making it harder to make data-driven decisions. This results in higher operational costs and reduced efficiency. DBR77 IoT provides comprehensive process monitoring, delivering precise, real-time data from every critical point in production.

DBR77 IoT

DBR77 IoT – A Comprehensive Solution for Process Monitoring DBR77 IoT is a holistic and flexible solution that offers full insight into key production and logistics operations. It gathers only the essential information needed to improve efficiency and productivity, whether on the production floor or in a logistics center.

Key Features of the DBR77 IoT System

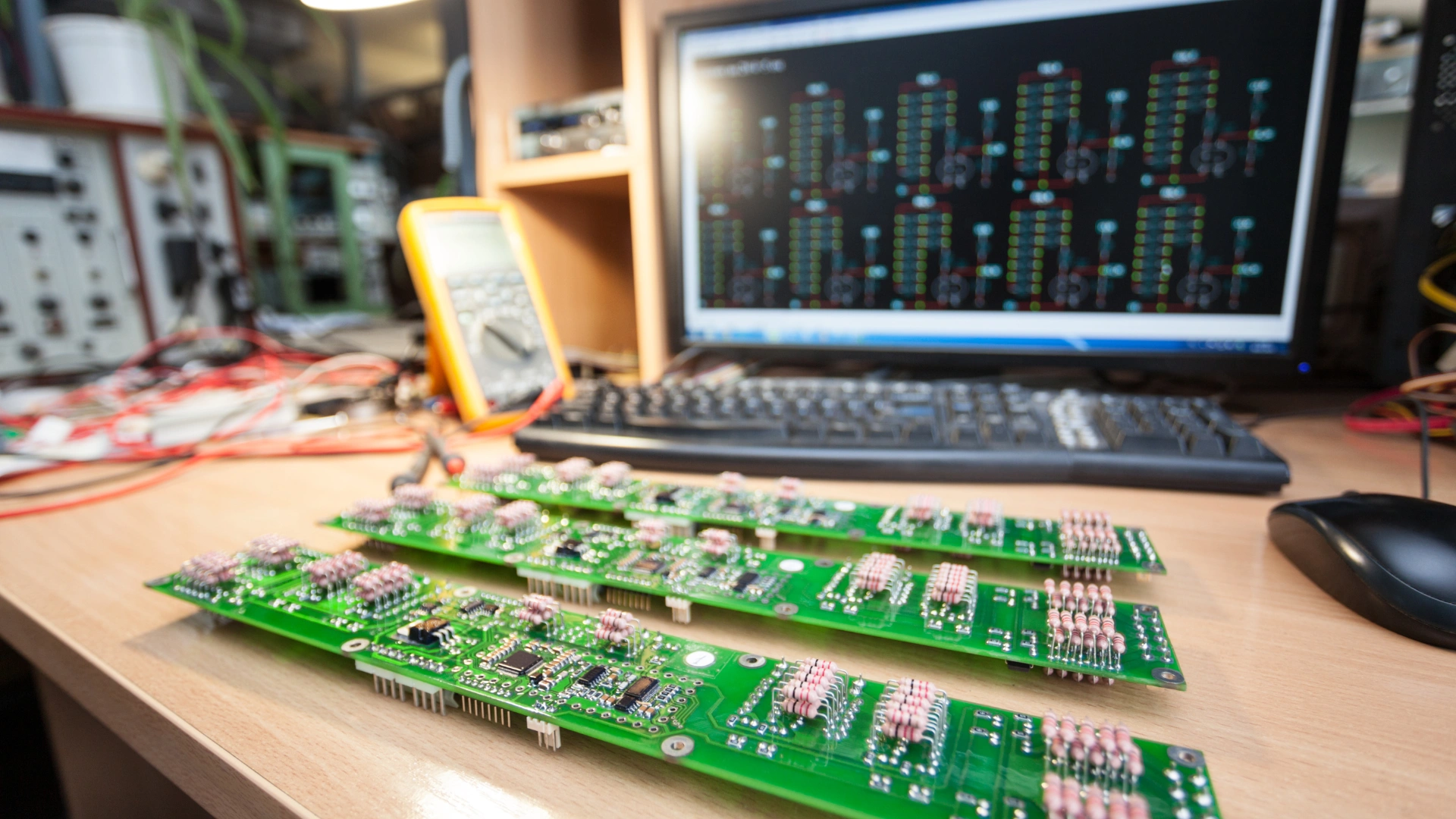

1. Data Collection System

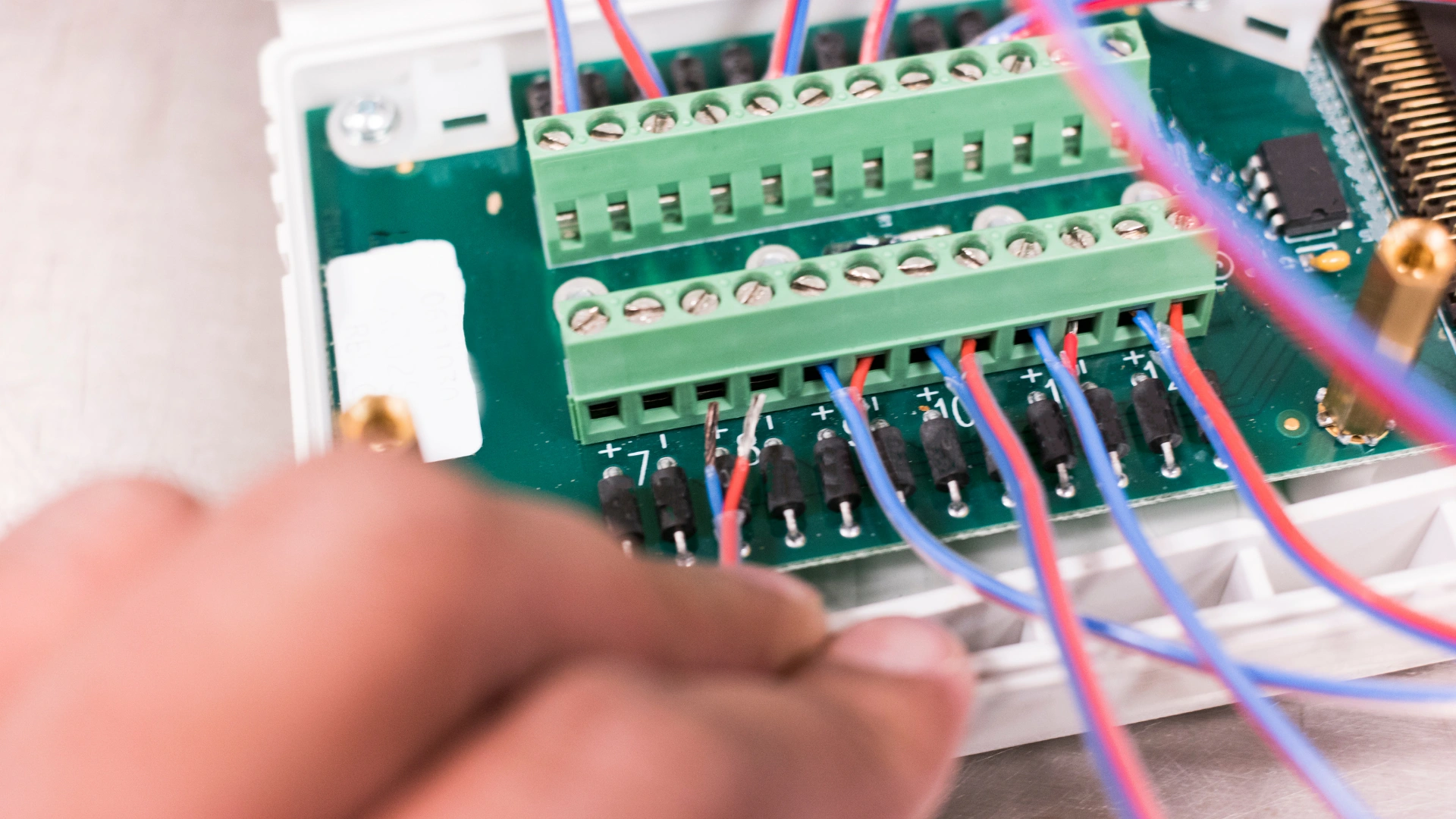

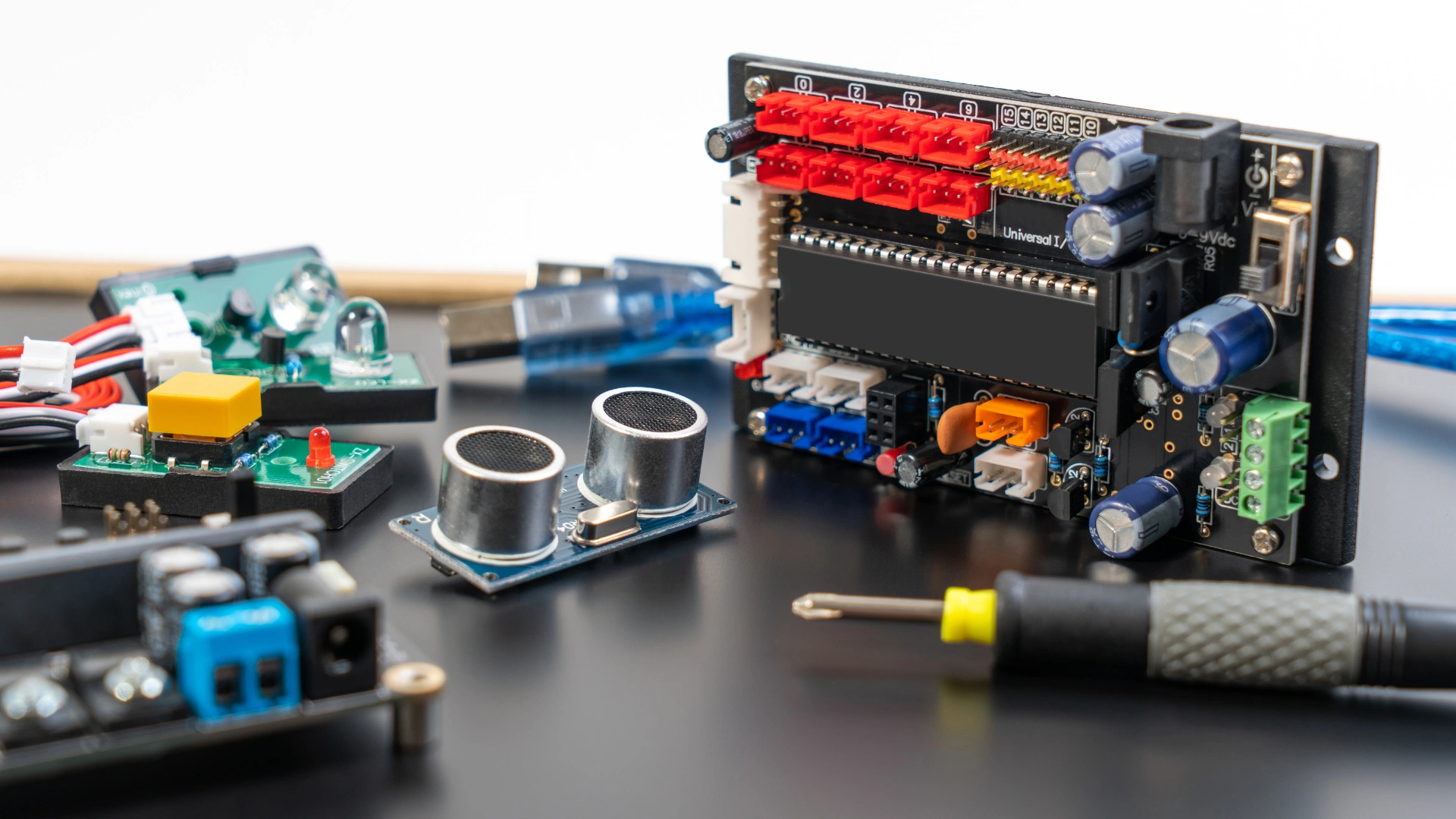

DBR77 IoT ensures full process oversight by collecting data from machines (performance, energy consumption), external sensors on assets, manual reporting decks, and a web app for entering data manually where sensor installation isn’t feasible.

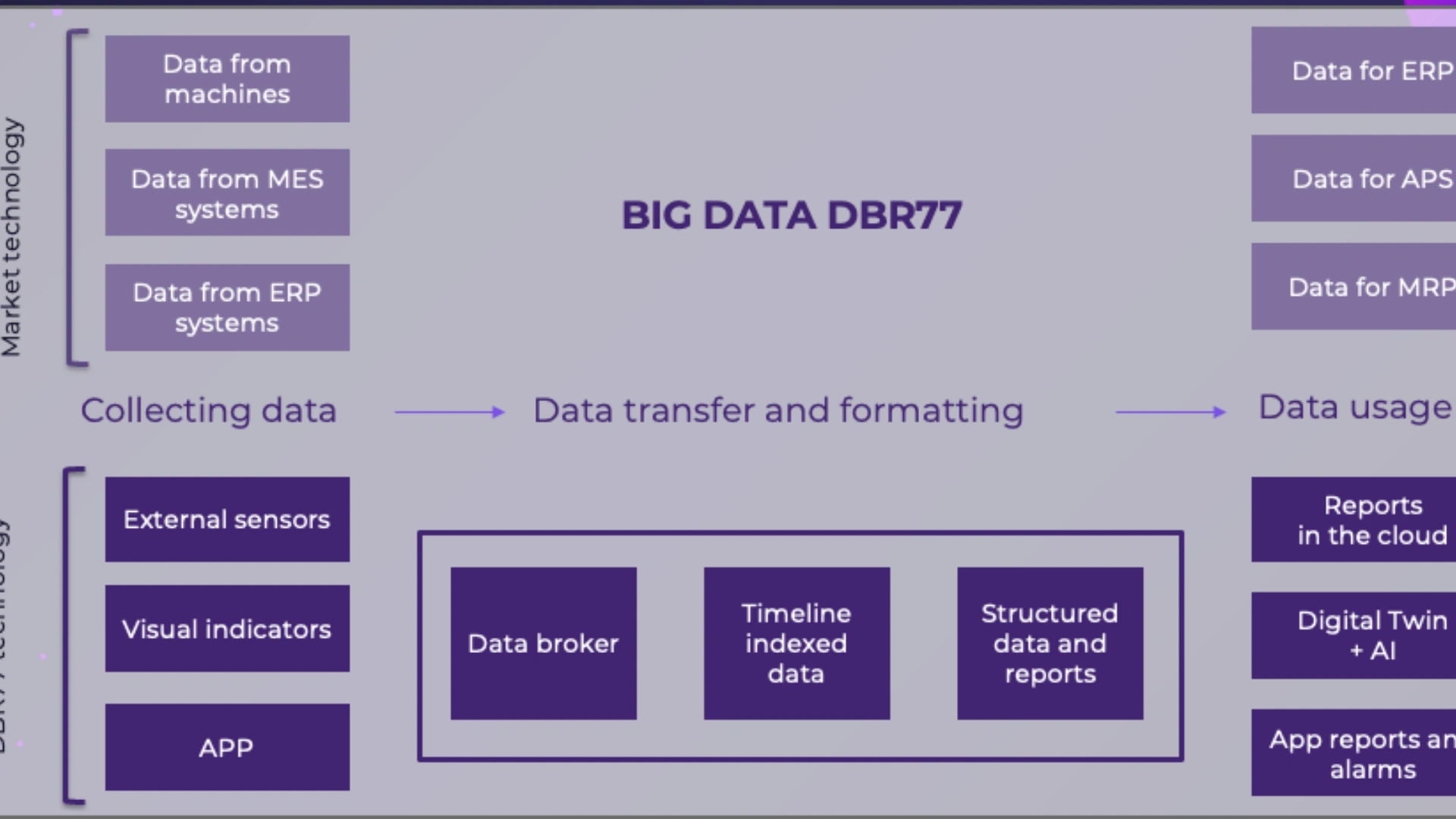

2. Data Transmission Systems

The module ensures secure and stable data transmission to the DBR77 cloud. It utilizes data brokers (physical network or Wi-Fi), SIM card connections for mobile transfer, and an autonomous self-detection system that monitors failures and threats, providing real-time issue notifications.

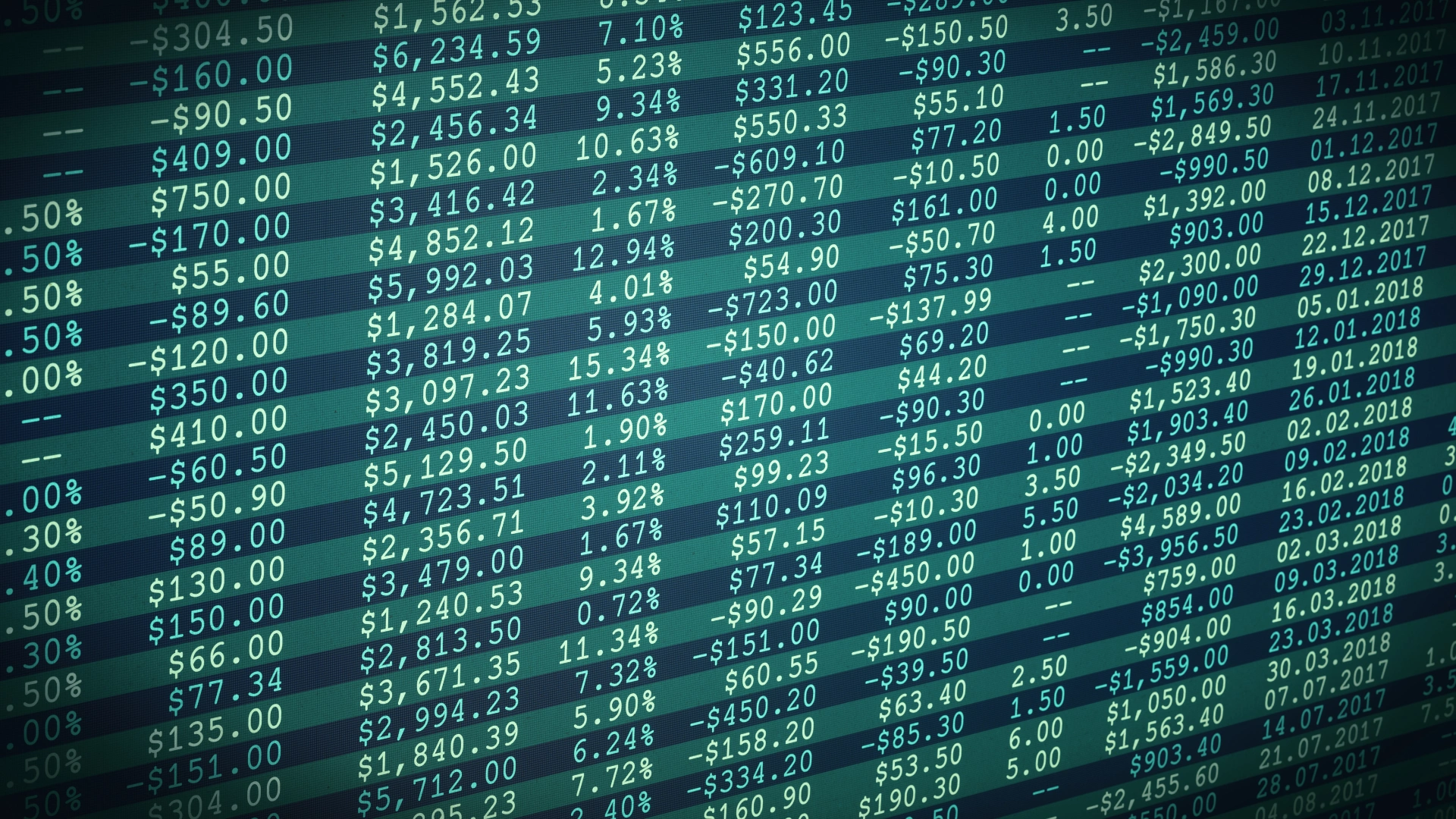

3. Data Validation and Archiving System

The DBR77 cloud system ensures data consistency and reliability. Time-series indexing allows for the validation of archive completeness and integrity, while algorithmic analysis of unusual events detects anomalies, enabling a rapid response and minimizing potential risks.

4. Data Utilization

The collected data supports process optimization and operational efficiency. It generates real-time reports and alerts, allowing for swift failure response. The system establishes operational time standards and integrates data with other systems, improving information flow within the organization.

Benefits of DBR77 IoT

How it works?

How Data is Collected

The DBR77 IoT system uses physical sensors to record performance, energy consumption, downtime, and failures. For areas without sensors, operators manually enter data through apps or reporting tools to provide a complete operational view.

Communication with the Cloud

Data is transmitted to the DBR77 cloud via a physical network, Wi-Fi, or SIM cards. The transmission module applies encryption, ensuring secure and stable data transfer, which enables continuous real-time access.

Data Storage and Analysis

Data is archived, validated, and analyzed using machine-learning-based algorithms. The system detects patterns, identifies anomalies, and predicts failures, aiding in process optimization and operational improvements.

Process Control and Optimization

The system monitors processes in real time, generating reports and alerts. The digital twin simulates scenarios and optimizes operations, enabling effective management and quick adaptation to changes.

Features and capabilities of the DBR77 IoT system

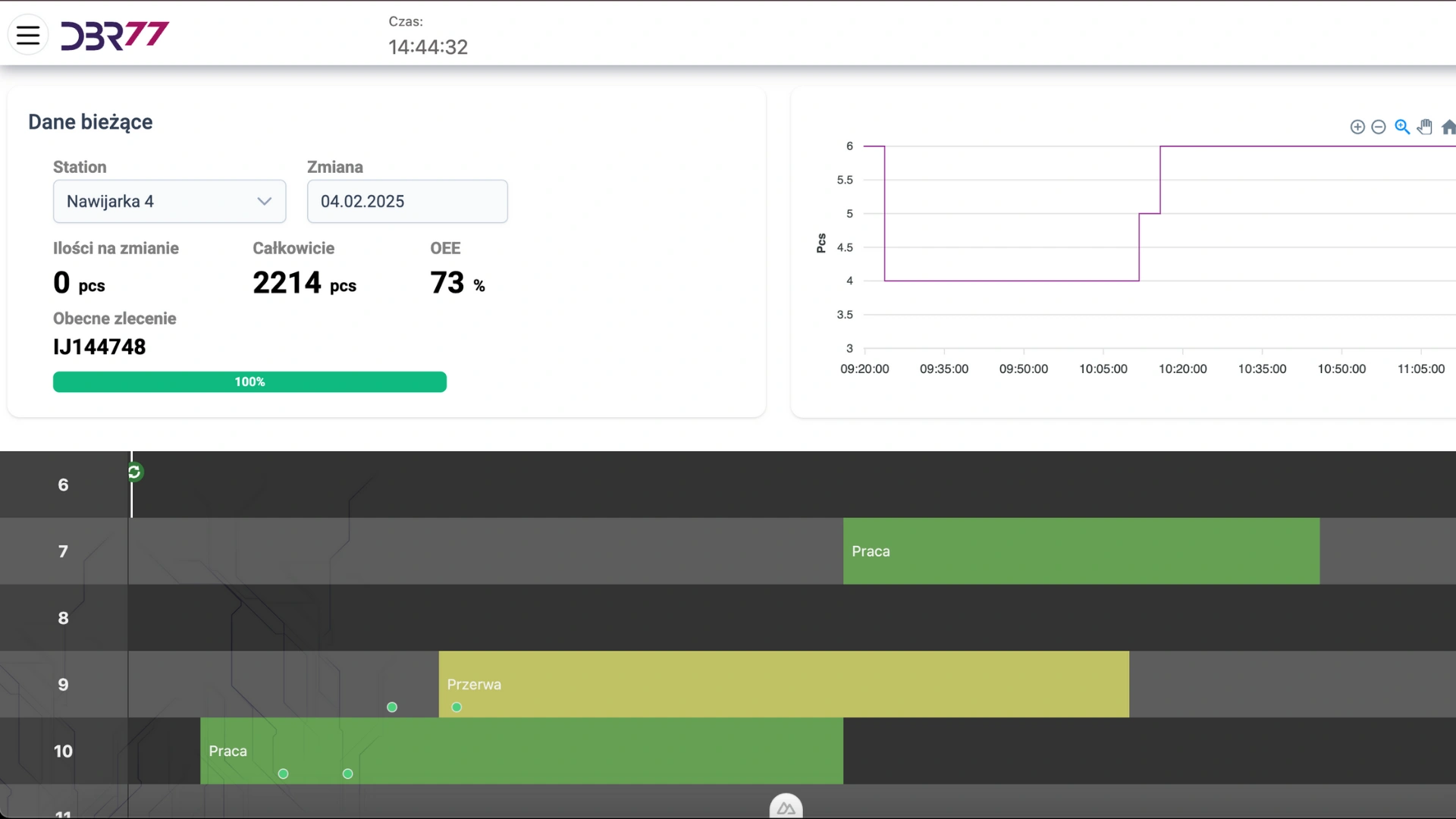

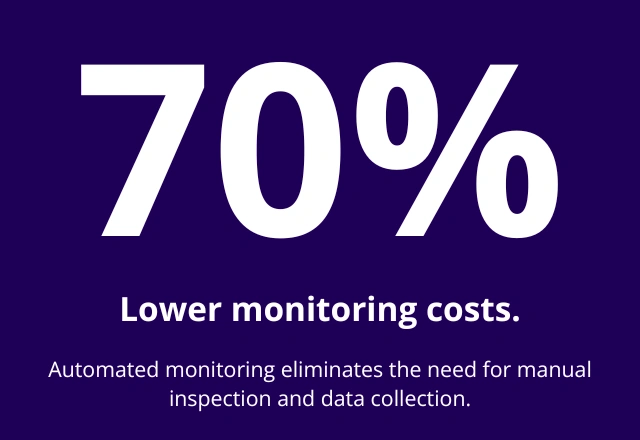

1. Automation of data collection

The system automatically collects data from machines and stations, eliminating the need for manual reporting and providing quick access to up-to-date information.

2 Monitor efficiency and optimize resources

IoT DBR77 tracks key metrics such as machine performance and energy consumption, supporting better planning and resource utilization and waste avoidance.

3. Real-Time Analysis and Reporting

Collected data is analyzed continuously, with results presented in reports. Automatic alerts on downtimes and failures facilitate a rapid response.

4. Decision Support and Digital Twin Integration

The system collaborates with the digital twin, enabling process simulation and optimization. Integration with MES and ERP systems supports data synchronization across the entire company.

Key Benefits of IoT DBR77

1. Complete Process Control

Real-time automated data collection ensures constant oversight of production and logistics, increasing operational precision and predictability.

2. Enhanced Efficiency and Performance

The system identifies areas needing optimization, eliminating losses, improving resource utilization, and boosting process performance..

3. Reduction of Operational Costs

Automated monitoring and data analysis help quickly identify issues, minimizing downtime risks and failures, ultimately reducing production costs.

4. Support in Making Informed Decisions

Through real-time analysis and reports, the system provides essential data for quick responses and strategic planning, supporting the company’s long-term growth..

Technology

DBR77 is a unique technology combining IoT, Digital Twins, and automation in one ready-to-deploy solution for industry. It enables real-time process monitoring and optimization without complex integration, offering full flexibility and scalability for various types of production. Developed by industry experts, it is intuitive and focused on addressing real operational challenges. Integration with Digital Twins enables testing changes before implementation, ensuring rapid and accurate decisions.

See how IoT DBR77 can revolutionize production management in your facility

Why Choose This Product

Immediate Access to Data – Provides continuous, real-time insights into facility operations, enabling swift decision-making.

Easy Integration – A ready-to-deploy system that requires no complex integration with existing infrastructure.

Flexibility and Scalability – Adapts to the needs of companies of various sizes and production types, supporting growth at every stage.

Decision Support with Digital Twins – Enables operational simulations, allowing for safe testing and optimization of processes before implementing changes..

News

Case Study: How DBR77 Marketplace Stabilized Logistics for a Tier-1 Automotive Supplier (Ficomirrors)

In the automotive industry, where "just-in-time" production is the standard, material flow stability is the ultimate currency. Discover how...

How has the direction of robotization changed over recent years?

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes....

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely...