The Problem We Solve

CTOs in manufacturing and logistics face the challenge of selecting the right technologies to drive facility development and process optimization. The lack of comprehensive simulation tools and difficulties in verifying suppliers make it harder to choose the best solutions. In a crowded marketplace, finding technologies tailored to specific needs and reliable implementation partners is critical.

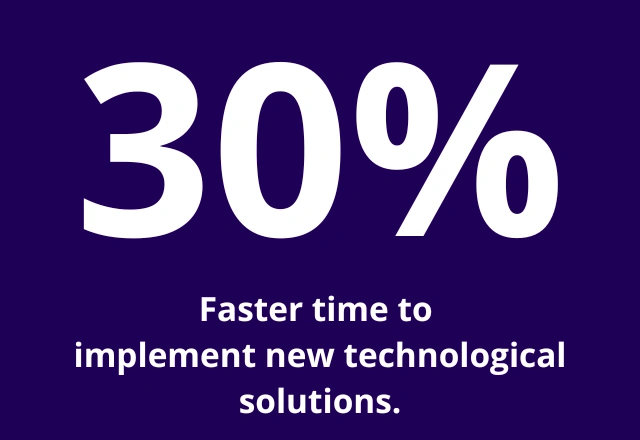

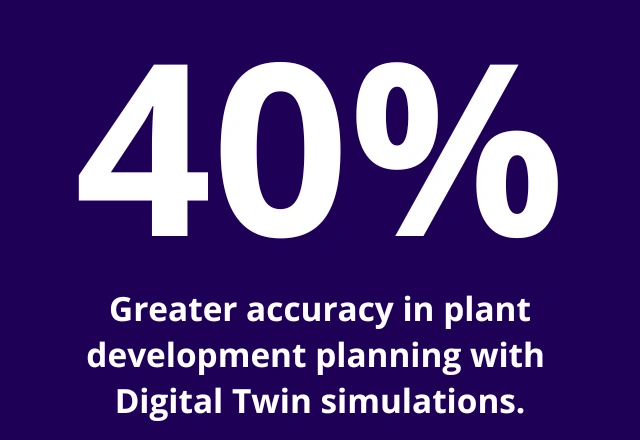

Results in Numbers

DBR77 Solutions

DBR77 provides CTOs with comprehensive support, offering:

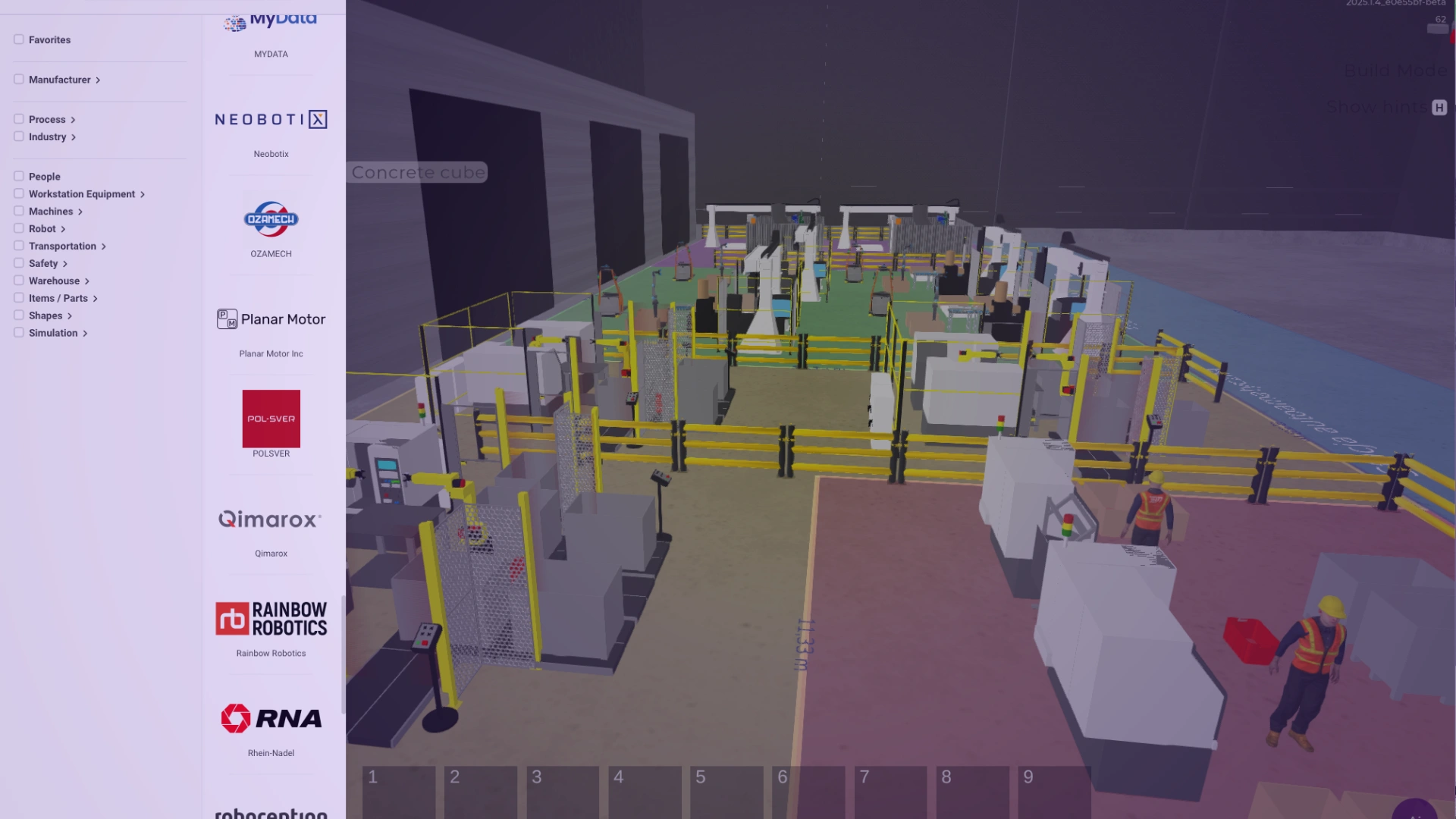

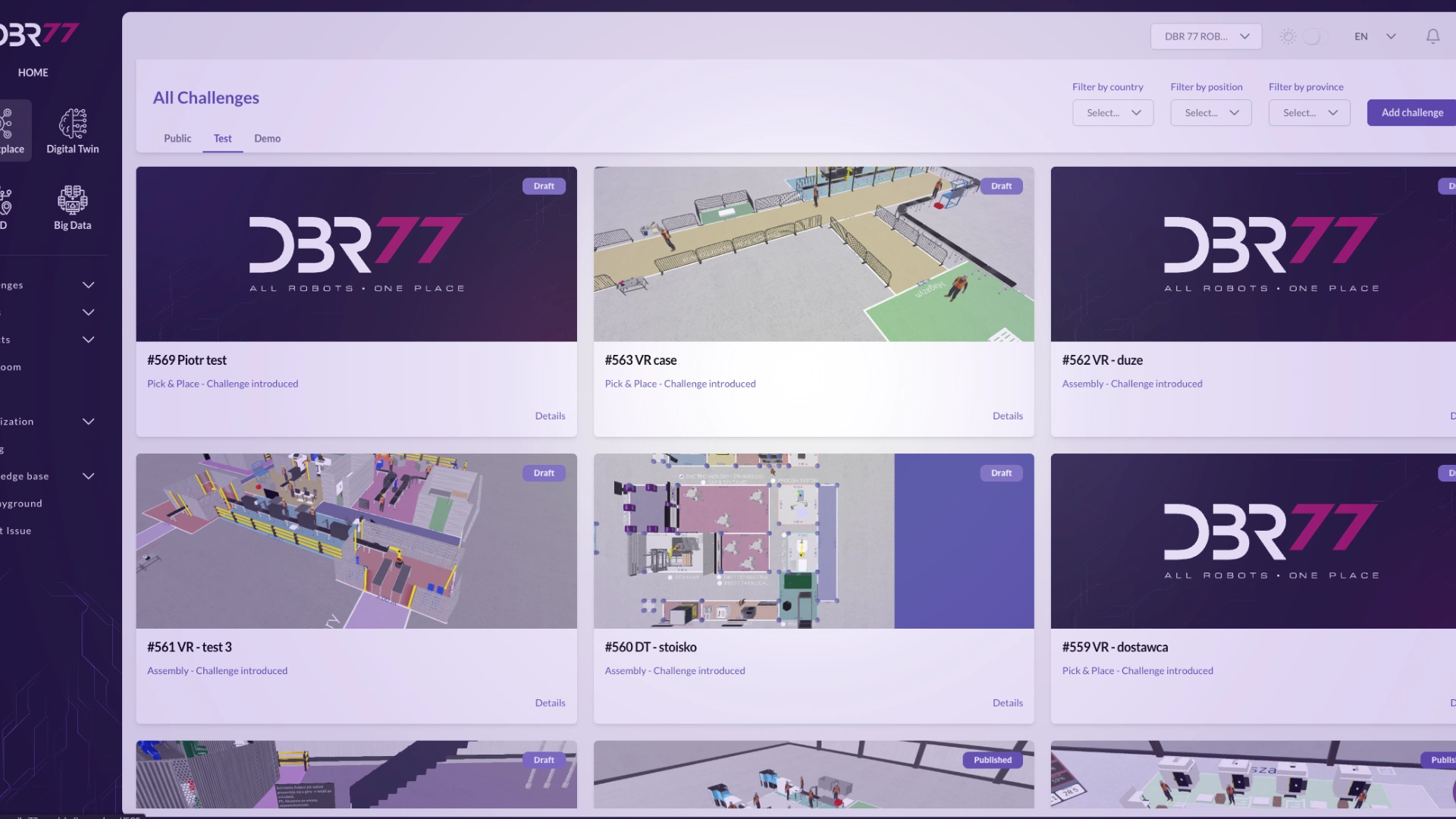

Digital Twin Simulations

Realistic process and production layout simulations allow precise planning, error elimination, and optimization in a secure virtual environment.

Access to the Best Technology Suppliers

The marketplace platform allows CTOs to quickly compare offers from leading technology providers. The selection process becomes more efficient, enabling the choice of the most advantageous solution tailored to the needs of the production facility.

Ease of Integration and Implementation

DBR77 facilitates seamless integration of selected solutions with existing IT systems and machinery. It enables rapid technology deployment, minimizing operational disruptions and reducing the time required to launch projects.

Comprehensive Solution

DBR77 provides support at every stage: from process analysis and measurement to performance improvement and advanced automation. This all-in-one tool helps CTOs optimize operations and build a modern, integrated production environment.

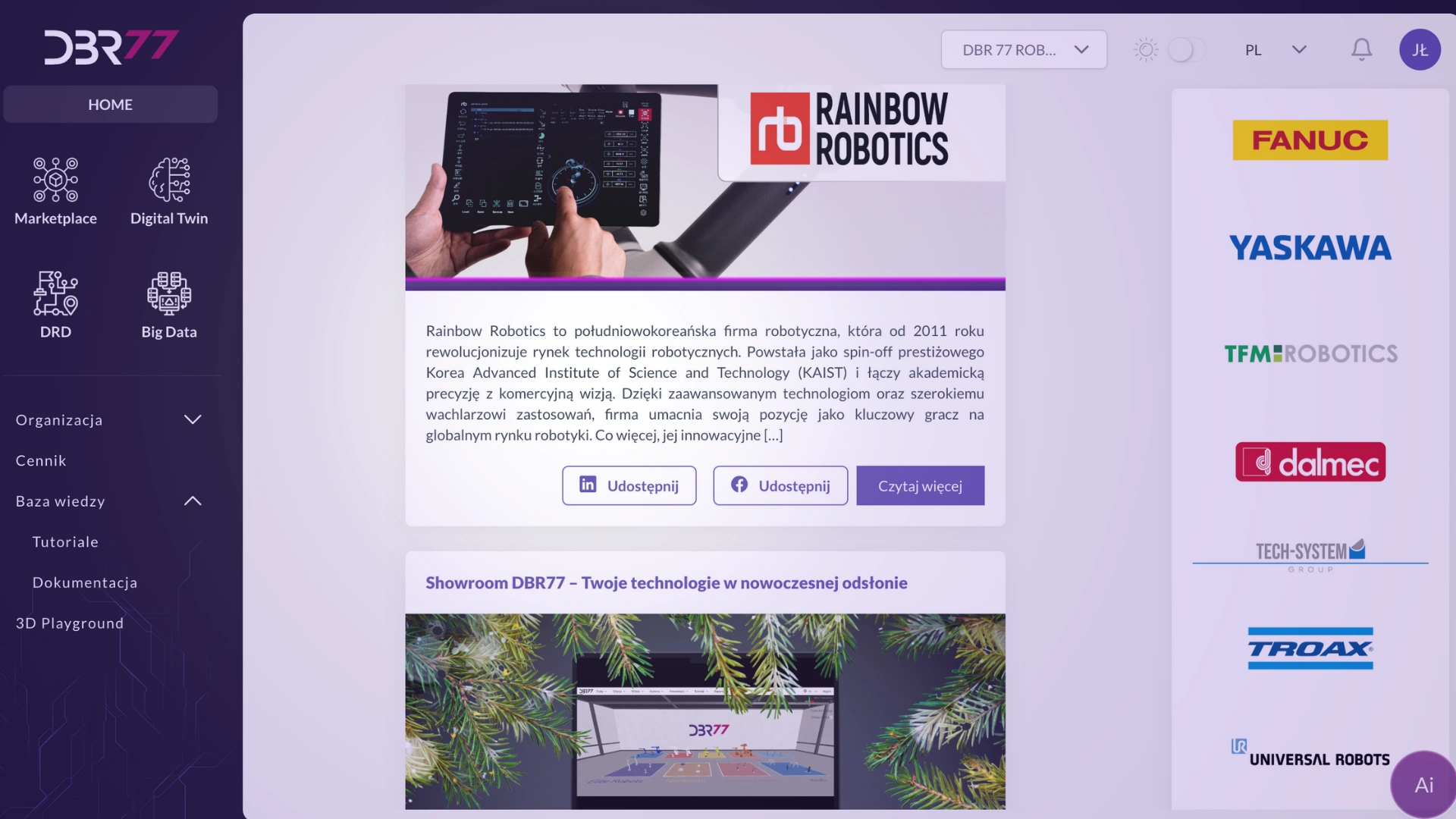

Technology

DBR77 is an integrated system consisting of three modules: data collection (IoT), efficiency improvement (Digital Twin), and automation (Marketplace), which collectively support operational transformation. The system operates in a flexible cloud environment, ensuring accessibility from any location. Its built-in AI Assistant and VR/AR functionalities enable detailed analysis and process visualization, facilitating optimal technological decision-making.

Why Choose DBR77?

Proven Technology

DBR77 is a trusted solution among global industrial leaders. It guarantees reliability, high quality, and scalability, enabling manufacturing facilities to safely adopt new technologies while maintaining operational continuity.

Precise Digital Twin Simulations

DBR77’s advanced simulation tools enable CTOs to realistically replicate production processes and factory layouts. This improves planning, optimizes resource allocation, and minimizes costs and risks by eliminating errors at the design stage.

Marketplace with Access to Leading Technology Providers

DBR77 offers an integrated platform featuring top technology suppliers. It allows for quick comparison, selection, and implementation of solutions tailored to production needs, accelerating the modernization and development of manufacturing facilities.

News

Advanced Manufacturing (ADMA): The European Path to Sustainable and Human-Centric Industry 5.0

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely...

RoadMap: Why Industrial Intelligence Begins with Measurement, Not a Robot Purchase?

Industrial Intelligence: Measure – Optimize – Automate. Path to success - Digital Development RoadMap We are entering 2026, a year where technology...

DBR77 Global Deployment: From Tokyo to Charlotte. Leading the AI Industrial Revolution in January 2026

January 2026 marks a historic milestone for DBR77 Global Deployment. In a simultaneous global push, our team is deploying on three fronts: opening...