In the automotive industry, where “just-in-time” production is the standard, material flow stability is the ultimate currency. Discover how Ficomirrors Polska utilized the DBR77 Marketplace platform to identify the ideal AGV technology provider and eliminate logistical bottlenecks.

The Challenge: Decoupling the Process from Human Factors

Ficomirrors Polska Sp. z o.o., a Tier-1 manufacturing facility belonging to the Ficosa International group, faced the critical challenge of stabilizing internal transport between production lines and warehouse zones. The primary issue was the logistical process’s heavy dependence on the immediate availability of manual operators, which led to downtime and performance fluctuations. Additionally, implementing solutions that guaranteed the highest safety standards was mandatory in zones shared by humans and machines.

The Solution: The Selection Process on DBR77 Marketplace

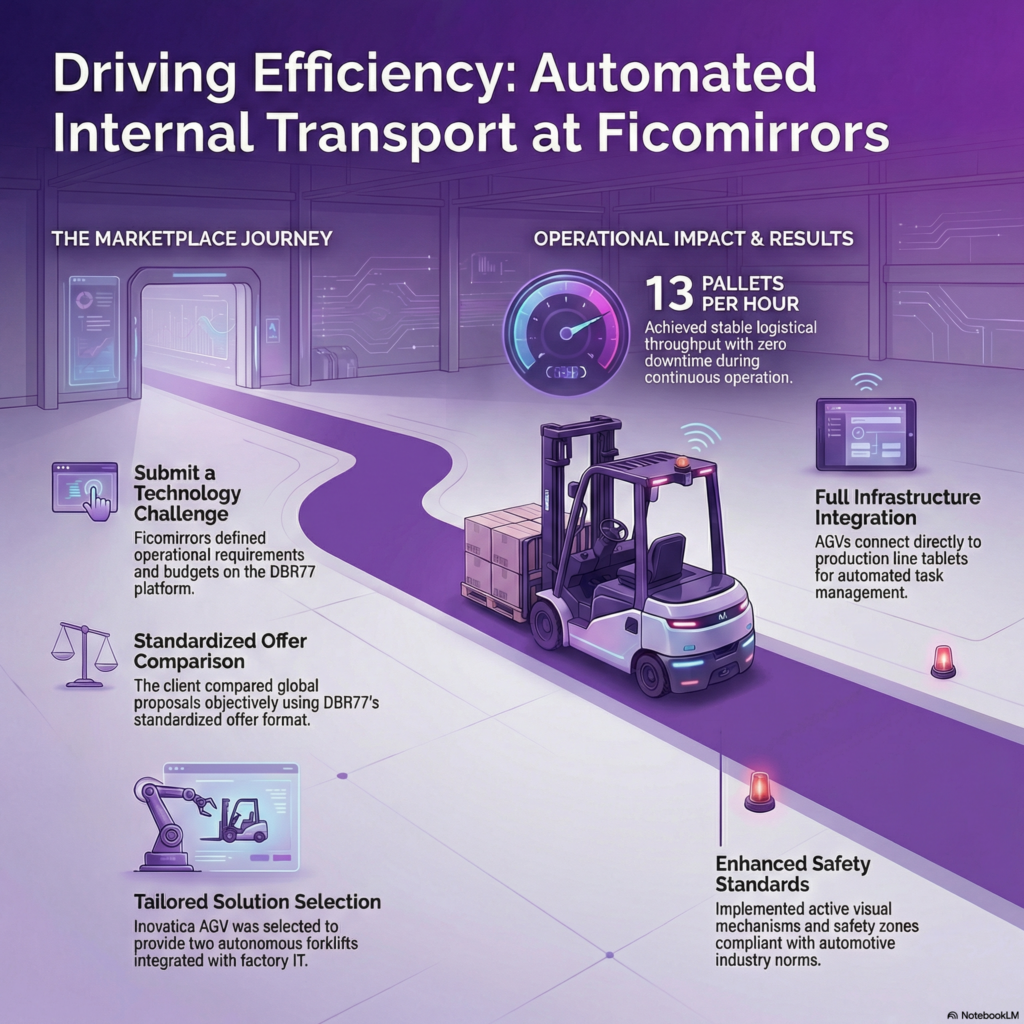

Instead of a traditional, time-consuming supplier search, Ficomirrors leveraged the digital ecosystem of the DBR77 Marketplace. The process followed three key steps:

1. Posting the “Technology Challenge” The company defined its operational needs and budget by publishing a specific “Technology Challenge” on the platform. This allowed for a precise specification of requirements, such as integration with existing IT infrastructure and the specific handling of pallets weighing up to 250 kg.

2. Comparing Standardized Offers Thanks to the platform’s mechanisms, Ficomirrors received proposals from various integrators in a unified, standardized format. This is a key advantage of the DBR77 Marketplace—the client could objectively compare offers based on functionality, costs, and system compatibility, avoiding the interpretative chaos often found with differing commercial proposal formats.

3. Selecting the Best Fit – Inovatica AGV From the submitted proposals, the solution from Inovatica AGV was selected as the best fit for the plant’s specific needs. The implementation included a system of two autonomous forklifts, fully integrated with tablets at the production lines and the master system.

Implementation Results

By selecting the right provider through the Marketplace, Ficomirrors achieved measurable business and operational benefits:

• Process Stability: The system handles up to 13 pallets per hour in continuous mode, eliminating downtime resulting from transport unavailability.

• Safety: Active visual mechanisms and dynamic safety zones were implemented, allowing for secure coexistence of robots and humans.

• Resource Optimization: Employees were relieved from heavy physical tasks, and the automated circulation of empty packaging organized traffic on the shop floor.

• Scalability: The system was designed to allow for easy expansion with additional AGVs or production lines without the need for hall reorganization.

Summary

The Ficomirrors case demonstrates that the key to successful robotization is not just purchasing a machine, but the technology selection process itself. The DBR77 Marketplace enabled the client to move from problem definition to solution implementation in a transparent, fast, and data-driven manner.