by Tomasz Jankowski | Feb 23, 2026 | Blog

In the high-stakes world of global manufacturing, intuition is no longer enough. Decisions involving millions of dollars in CAPEX require rigorous, data-backed justification. Enter the Smart Industry Readiness Index (SIRI) – a framework that has transcended its...

by Tomasz Jankowski | Feb 16, 2026 | Blog

The direction of robotization has shifted radically: from simply replacing muscle power to integrating AI-supported decision-making processes. Today, the competitiveness of your plant no longer depends solely on the number of robots you have, but on the intelligence...

by Tomasz Jankowski | Feb 9, 2026 | Blog

The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely technocratic view toward a holistic vision that integrates sustainability and human talent. For European manufacturers,...

by Tomasz Jankowski | Sep 25, 2025 | News, News

This week, our leaders laid out a bold vision. Torian Richardson spoke of building a true Makers Network, and our CEO, Piotr Wiśniewski, Ph.D., explained the global strategy behind our American launch. But one question remains: Why North Carolina? The answer is...

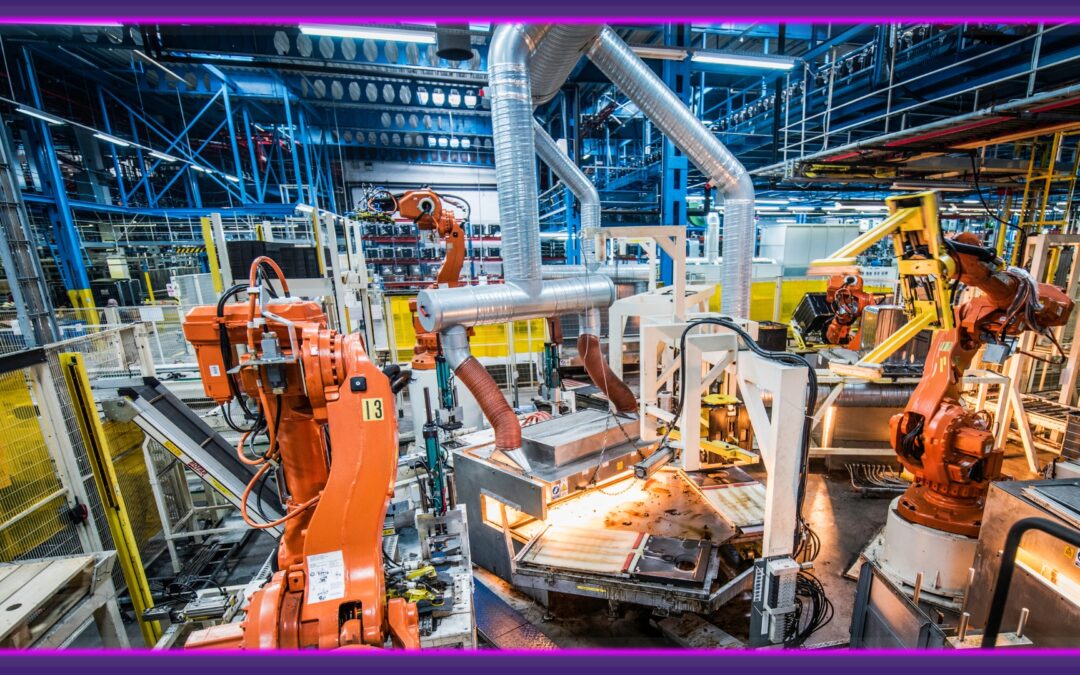

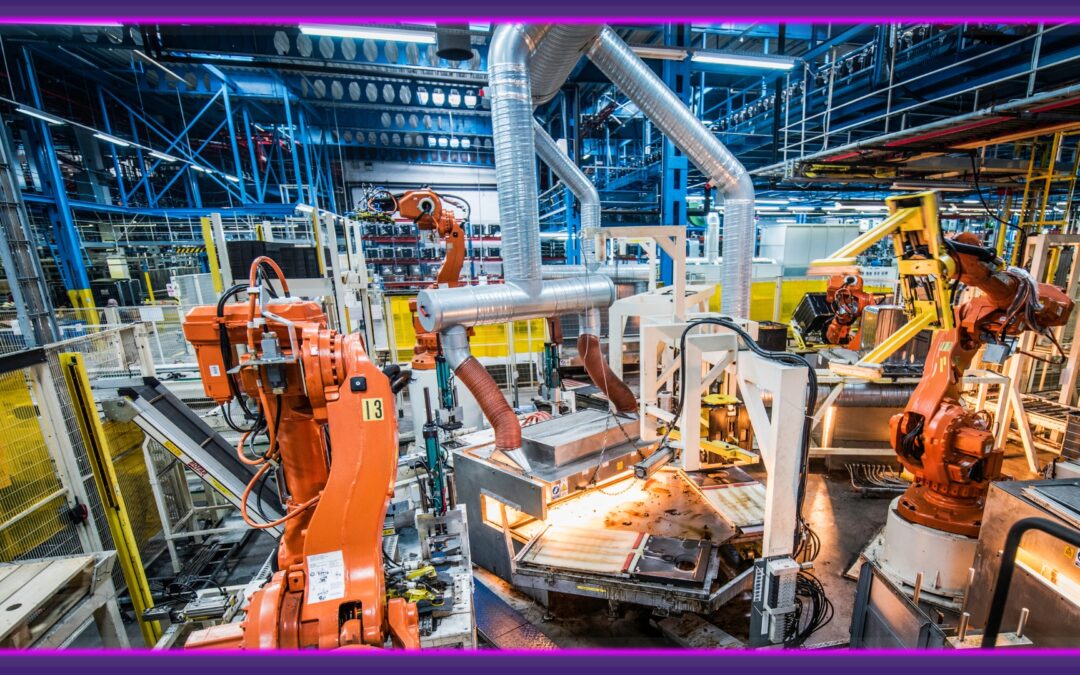

by Tomasz Jankowski | Aug 10, 2025 | Blog

Accurately determining production capacity and establishing realistic work standards are critical for efficient manufacturing. Without precise data, companies risk overloading resources, missing deadlines, or underutilizing equipment. This post explores how...

Recent Comments