Innovation versus fear: The biggest pitfall of digitization

Anyone who manages production knows this scenario all too well. You’re standing in the hall, watching the line work, and suddenly a thought about production optimization pops into your head: “What if we…?” A brilliant idea sprouts in your head for changing the layout, improving the flow, implementing new technology. It’s a vision of huge savings and a leap in productivity.

And then… reality sets in.

The brainstorming in your head quickly turns into a list of risky questions:

- How many production days will we lose due to retooling and testing?

- What if our Excel simulation did not take all variables into account?

- How can you convince management to invest when you are not 100% sure that it will work?

As a result, most brilliant ideas never make it past the PowerPoint presentation stage. Innovation loses out to the fear of costly mistakes. There is another, often overlooked pitfall: the digitization of chaos. Many companies invest in modern technologies to automate processes that are inherently unstable and wasteful. The result? Faster and more precise production of losses.

The good news? There is a way to avoid both of these pitfalls.

A partnership that puts everything in the right order

We are therefore announcing a partnership between DBR77 and FlowDynamic Project – optimization experts with over 25 years of experience in the most demanding industries. This alliance combines deep process knowledge with the most powerful simulation technology to give industrial companies a complete and secure path to operational excellence.

The key is FlowDynamic Project’s unique two-step philosophy: First stabilize. Then simulate and implement.

Stage 1: Foundations, or a process ready for the future

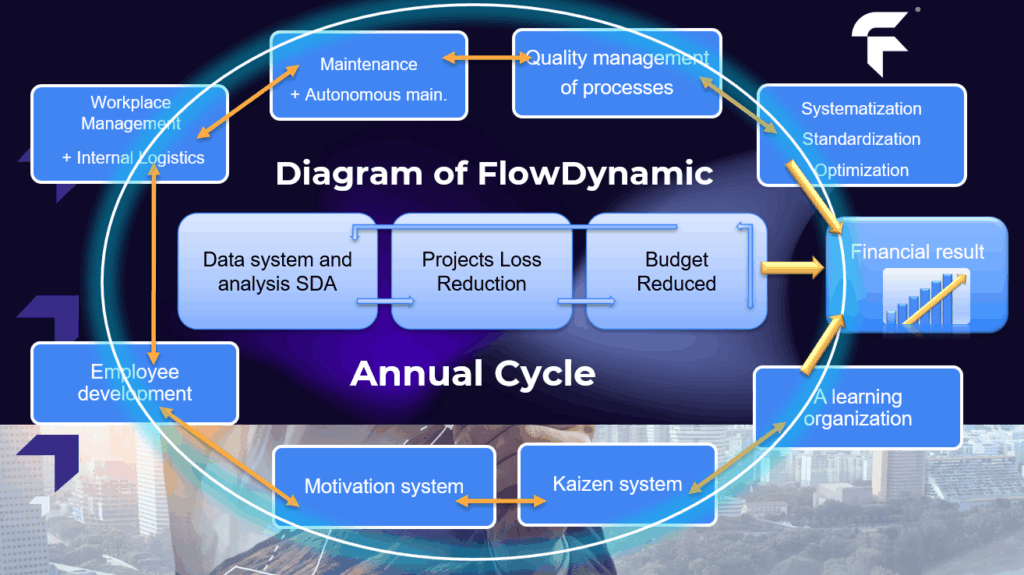

Before we even think about advanced technology, FlowDynamic Project brings order. Their proprietary FlowDynamic production management system focuses on building a solid organizational foundation. This is grassroots work that includes identifying and eliminating waste, organizing the workplace, autonomous and professional maintenance, standardization, optimizing internal logistics, and improving quality management built into the process.

The result? Processes become stable, repeatable, and waste-free. As confirmed by the FlowDynamic Project experience, companies can reduce manufacturing costs by 15% to as much as 30% at this stage alone. This approach creates a solid foundation on which to safely build a digital future. Learn more about our case studies.

Stage 2: Superpowers, or testing the future in the Digital Twin

Once the process is streamlined and efficient, the question arises: “What next? How can we be even better?” And this is where the Digital Twin from DBR77 comes into play.

It is a dynamic, virtual replica of the plant’s production and logistics processes. Instead of risky experiments on a live factory, we give FlowDynamic Project experts the world’s most powerful tool for testing the most ambitious ideas.

How does it work in practice?

Virtual replica: we create a digital copy of your already optimized production process.

The “What if?” laboratory: in this virtual environment, we implement and test FlowDynamic Project ideas: a new line, advanced robotization, a completely different logistics system, and the ergonomics of your workstation.

Hard data: within hours, not months, you get a precise answer on how a given change will affect OEE, throughput, costs, and return on investment.

No more guesswork and theoretical models. Thanks to this collaboration, you can see the future of your factory and choose the best scenario based on hard data from simulations.

A new era in industrial consulting: Certainty instead of theory

“A new era is dawning in industrial consulting,” says a representative of FlowDynamic Project. “Our customers no longer need just theory, they need certainty. The DBR77 Digital Twin gives us the ability to provide that certainty. We can verify every concept and show its real impact on the business before anyone on the shop floor picks up a tool. This is tremendous value and risk reduction that simply did not exist in the market until now.”

This partnership is truly changing the way we think about innovation in industry. Gone is the paralyzing fear of change.

Główne korzyści dla Twojej firmy – czarno na białym:

Minimizing investment risk by testing ideas in a virtual environment before implementing them on the shop floor.

Accelerate your return on investment (ROI) by choosing the most effective solutions confirmed in simulations.

Testing multiple scenarios and selecting the optimal development path without incurring additional costs.

Decisions based on hard data that accurately predict the impact of changes on key performance indicators.

Frequently asked questions (FAQ)

1. What exactly is a Digital Twin? A Digital Twin is a virtual, dynamic simulation of your real production and logistics processes. It allows you to test changes in a digital environment before they are implemented in reality, eliminating the risks and costs of experimentation.

2. Does my company need to have optimized processes in place to benefit from Digital Twin? Not necessarily. Our partnership is based on two stages. First, experts from FlowDynamic Project help stabilize and streamline current processes. Only then, on this prepared ground, do we build the Digital Twin to seek further breakthrough improvements.

3. What specific changes can I test in the simulation? Practically any. From changing the layout of the production line, through introducing new machines and robots, to testing new logistics strategies, changes in scheduling or quality management systems.

Test your idea before investing a single dollar.

Would you like to see how your best idea works in Digital Twin before investing time and money in it?