The Advanced Manufacturing (ADMA) methodology represents a paradigm shift in how we evaluate industrial progress, moving away from a purely technocratic view toward a holistic vision that integrates sustainability and human talent. For European manufacturers, particularly Small and Medium-sized Enterprises (SMEs), ADMA is not just an assessment tool; it is a strategic blueprint for becoming a “Factory of the Future” by aligning digital adoption with the emerging principles of Industry 5.0.

What is ADMA and How Does it Work in Practice?

In the crowded landscape of digital maturity models, ADMA stands out by rejecting the notion that technology is the sole driver of competitiveness. Originating from the European Commission’s initiative, ADMA was designed specifically to address the unique challenges of the European manufacturing sector, which is characterized by high labor costs, strict environmental regulations, and a reliance on skilled craftsmanship rather than mass, low-cost labor.

The methodology operates on the premise of “seven transformations.” Unlike other models that might group criteria into “IT” and “OT,” ADMA treats the factory as a living organism where social innovation is just as critical as technological innovation. In practice, an ADMA assessment begins with a “Scan” – a comprehensive diagnostic process that evaluates the company across these seven diverse axes.2 This is not merely a checklist of machines owned; it is an inquiry into the organization’s philosophy. For instance, it asks not only if you have robots but whether those robots are making work safer and more meaningful for your employees.2

This approach resonates deeply with the transition to Industry 5.0, where the focus shifts from “efficiency at all costs” to “resilient and sustainable production.” By using ADMA, companies essentially stress-test their operations against future regulatory pressures (like the EU Green Deal) and labor market shifts (the shortage of skilled workers), ensuring that their digital transformation is robust and future-proof.3

The Seven Transformations: A Deep Dive into the Factory of the Future

To truly understand the value of ADMA, one must dissect its seven core transformation areas. Each represents a pillar of a mature, modern enterprise.

1. Advanced Manufacturing Technologies

This pillar assesses the “hard” assets of the factory. However, ADMA distinguishes itself by looking beyond off-the-shelf purchases. It evaluates a company’s ability to adapt and engineer its own technological solutions to create a competitive moat. A mature company in this area doesn’t just buy a 3D printer; it integrates additive manufacturing into its supply chain to reduce lead times for spare parts.4 It explores whether the company is leveraging state-of-the-art hardware like collaborative robots (cobots) or advanced photonics to solve specific production bottlenecks rather than following hype cycles.

2. Digital Factory

Here, the focus is on the “digital thread” – the seamless flow of data from the top floor to the shop floor. ADMA evaluates the integration of physical and digital systems. Is the company using a Digital Twin to simulate products before production? Are paper-based work orders replaced by real-time digital dashboards? The goal is to eliminate information silos, ensuring that the design department, the production line, and the ERP system are speaking the same data language.1

3. ECO Factory

This is ADMA’s most distinct differentiator. While other models might treat sustainability as a “nice-to-have,” ADMA places it at the core. It assesses energy management, carbon footprint reduction, and circular economy practices.5 A mature ECO Factory views waste not just as trash but as a resource inefficiency. This includes recovering heat from compressors, recycling water, and designing products for easy disassembly. In an era of rising energy costs and carbon taxes, high maturity in this area directly correlates with long-term financial viability.

4. End-to-End Customer Focused Engineering

The days of “push” manufacturing are over. This area measures how deeply customer needs are integrated into the engineering process. It looks at the ability to offer mass customization without destroying profit margins. Mature companies use digital tools to co-create value with customers, allowing them to configure products online and feeding that data directly into production planning. This responsiveness is critical for SMEs competing against mass-market giants.

5. Human-Centered Organization

Perhaps the most “Industry 5.0” aspect of ADMA, this transformation evaluates how technology serves the worker. It asks: Is the company investing in upskilling? Are digital tools used to reduce cognitive load (e.g., Augmented Reality instructions) or physical strain (e.g., exoskeletons)? It promotes a culture where innovation is driven by the shop floor, fostering high levels of employee autonomy and engagement. This is crucial for retention in a tight labor market.2

6. Smart Manufacturing

This refers to the intelligence of the production system itself. It goes beyond automation to “autonomation” – systems that can self-correct and optimize. This involves the use of AI and machine learning for predictive maintenance (anticipating breakdowns before they happen) and adaptive scheduling. A Smart Factory reacts to changes in demand or material availability in real-time without manual intervention.2

7. Value Chain Oriented Open Factory

Finally, ADMA recognizes that no factory is an island. This area assesses the company’s openness to the ecosystem. It encourages “Open Innovation” – collaborating with universities, research centers, and even other companies in the supply chain to solve complex problems. It measures the digital integration with suppliers and logistics partners to create a transparent, responsive value network.2

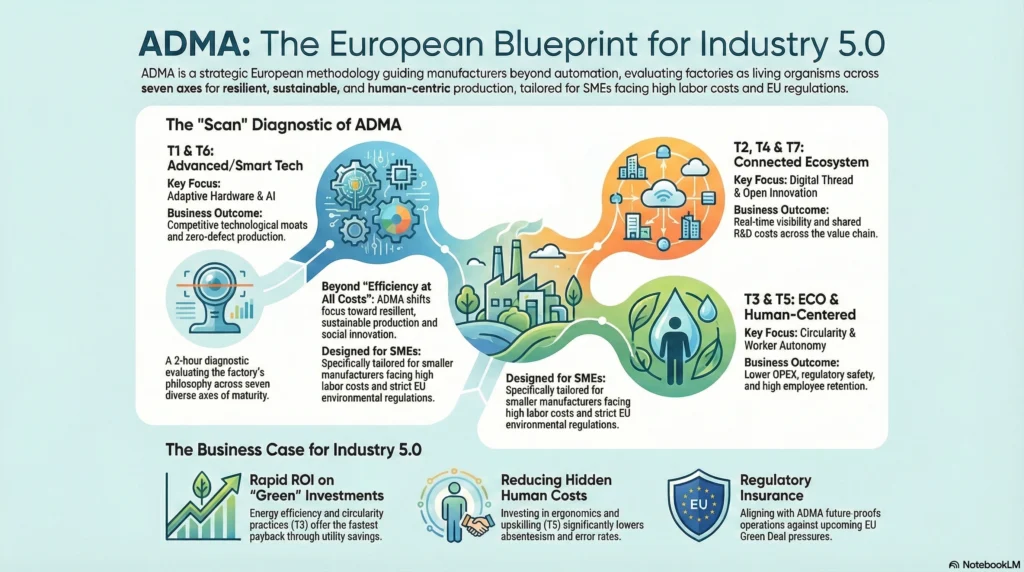

Figure 1: Beyond Automation. ADMA serves as a strategic guide for European manufacturers, shifting the focus from pure efficiency to resilience and sustainability to meet strict EU regulations.

ADMA vs. The Competition: Strategic Considerations

When a CEO considers ADMA, they are often weighing it against other options.

ADMA vs. Traditional Audits: Traditional consulting audits often focus heavily on financial metrics or lean process efficiency (waste reduction). While valuable, they often miss the “digital readiness” aspect. ADMA combines operational excellence with technological potential.

ADMA vs. Purely Technical Models: Unlike models that strictly count sensors and servers, ADMA provides a narrative about how technology is used. It prevents the common pitfall of investing in expensive technology that the workforce rejects or that harms the environment.

The Hidden Risks of ADMA

While robust, ADMA is not without its challenges.

- Subjectivity: The initial “Scan” is often a self-assessment. Without an external “TranS4MEr” (certified expert) to validate the answers, companies often overestimate their maturity, leading to a “false positive” diagnosis.7

- Breadth vs. Depth: Because it covers seven huge areas, it may not provide the granular technical architectural advice that a dedicated IT audit would. It tells you that you need a Digital Twin, but not necessarily which software architecture to use.

- The “Soft” Factor: Engineering-led organizations sometimes struggle with the “Human-Centered” and “Eco” pillars, viewing them as HR or PR issues rather than core operations. This cultural resistance can derail the implementation of the roadmap.6

Financial Implications: The Cost of Transformation

A common fear is that “Human-Centric” and “Eco” means “Expensive.” However, the ADMA logic flips this.

- Cost of Assessment: The scan itself is often low-cost or subsidized through EU Digital Innovation Hubs (DIHs), making it highly accessible to SMEs.8

- ROI of Eco: Investments in energy efficiency (T3) often have the fastest payback periods due to savings on utility bills.

- ROI of Human: Investments in ergonomics and digital support (T5) reduce absenteeism, turnover, and error rates, which are massive hidden costs in manufacturing.

Table 1.1: The 7 ADMA Transformations at a Glance

| Transformation Area | Key Focus | Outcome for the Business | Industry 5.0 Alignment |

| T1: Advanced Tech | Proprietary/Adapted Hardware | Competitive technological moat | Resilience |

| T2: Digital Factory | Connectivity & Paperless | Real-time data visibility | Efficiency |

| T3: ECO Factory | Sustainability & Circularity | Lower OPEX, Regulatory safety | Sustainability |

| T4: Customer Engineering | Mass Customization | Higher margins, Customer loyalty | Personalization |

| T5: Human-Centered | Autonomy & Upskilling | Retention, Innovation culture | Human-Centricity |

| T6: Smart Manufacturing | AI & Self-Optimization | Agility, Zero-defect production | Resilience |

| T7: Open Factory | Ecosystem Collaboration | Shared R&D costs, Supply chain agility | Resilience |

FAQ: Navigating the ADMA Journey

No, it was specifically designed for SMEs. The language and criteria are tailored to companies that may not have huge IT departments but need to modernize to survive.1

Yes, while it aligns with EU standards, the principles of sustainability and human-centricity are global. However, finding a certified “TranS4MEr” might be harder outside Europe.9

The initial Scan takes about 2-3 hours. The development of a full Transformation Plan with an expert usually takes 2-4 weeks of collaborative work.7

It helps you decide if and where you need robots (T1/T5). It prevents you from buying robots for the wrong reasons, but it is not a procurement platform itself.10

Why Choose ADMA in 2026?

If your organization perceives digital transformation not just as a hardware upgrade but as a cultural and strategic overhaul, ADMA is the superior choice. It ensures that your journey to digitalization does not leave your workforce or the planet behind. By aligning with the “Factory of the Future” standards, you are essentially purchasing an insurance policy against future regulatory and labor market shocks.

Author: Tomasz Jankowski, R&D Specialist, DBR77

R&D Specialist at DBR77, focusing on IT development, Digital Twin technology, and automation. He has a strong background in managing EU projects and conducting research work. A graduate of Nicolaus Copernicus University in Toruń, he combines scientific precision with the implementation of technological innovations.

Cited works

- 1. ADMA: European Advanced Manufacturing Support Centre – North Sea Region, NorthsearegionADMA: European Advanced Manufacturing Support Centre, Interreg VB North Sea Region Programme

- 2. ADMA Scan: Evaluate the Digital Maturity of Your Business – ImFactory, ComADMA Scan: Evaluate the Digital Maturity of Your Business – ImFactory

- 3. D7.1 ADMA-LCAMP FRAMEWORKS INTEGRATION, Lcamplcamp.eu/wp-content/uploads/sites/53/2024/07/D7.1-ADMA-LCAMP-FRAMEWORKS-INTEGRATION.-Final-Version-1.pdf

- 4. The Seven Categories of Additive Manufacturing Technologies – Altair, AltairThe Seven Categories of Additive Manufacturing Technologies

- 5. MEET THE ADVANCED MANUFACTURING CHAMPIONS – ADMA TRANS4MERS, Trans4merstrans4mers.eu/assets/content/attachments/20210702-ADMA-booklet_final.pdf

- 6. Meet our Factories of the Future: EMS-Electra SRL – ADMA TRANS4MERS, Trans4mersMeet our Factories of the Future: EMS-Electra SRL | ADMA

- 7. ADMA TranS4MErs SCAN, Trans4mersADMA TranS4MErs SCAN | ADMA

- 8. Transformation Programme – ADMA TRANS4MERS, Trans4mersTransformation Programme | ADMA

- 9. Open Call 2 – AFIL, Afilafil.it/wp-content/uploads/2023/04/ADMA_TranS4MErs_D4.1C_GuideForApplicants_V2.05.pdf

- 10. Transformation and Implementation Plan – ADMA TRANS4MERS, Trans4merstrans4mers.eu/assets/content/Resources/ADMA_TranS4MErs_Sample_Transformation_Plan.pdf